Leakproof rubber ring for gas pipeline

A gas pipeline and rubber ring technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve the problems of reduced sealing performance of the rubber ring and the connection is not particularly close, so as to prevent obstruction, the structure is simple, and it is easy to realize. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

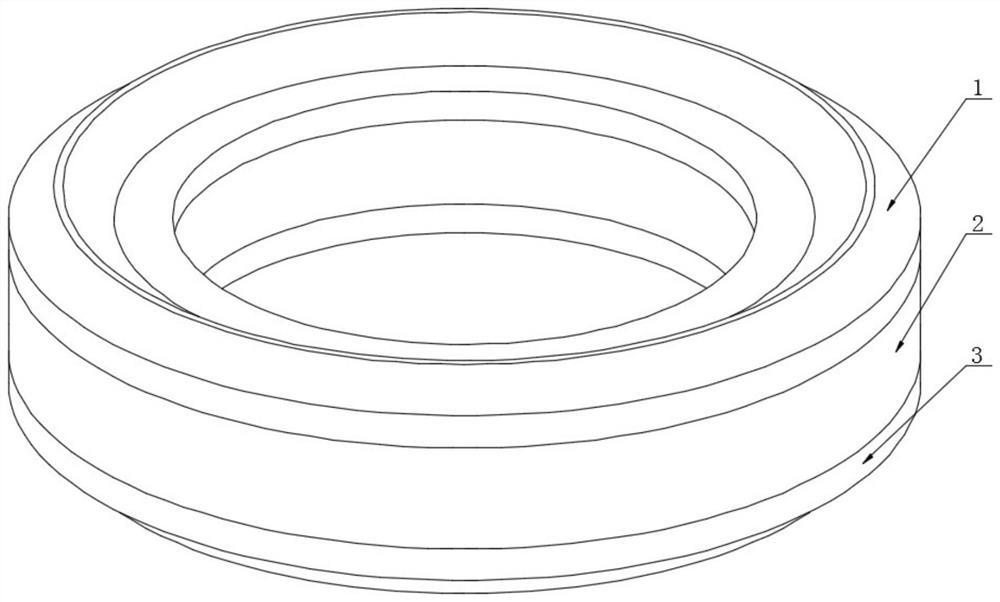

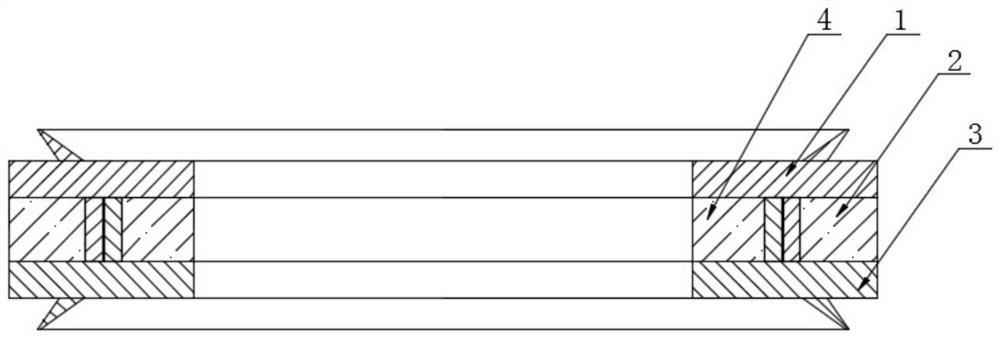

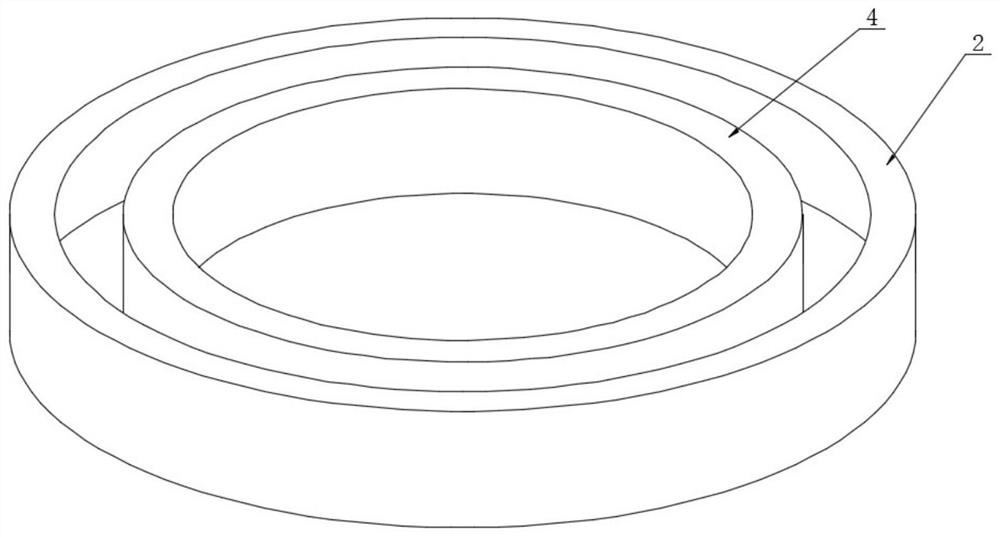

[0027] like Figure 1-5 As shown, an anti-leakage gas pipeline rubber ring includes a first sealing ring 1, a second sealing ring 3, an outer limiting ring 2 and an inner limiting ring 4, and the outer limiting ring 2 and the inner limiting ring 4 are located at Between the first sealing ring 1 and the second sealing ring 3, the first sealing ring 1 and the second sealing ring 3 are detachably connected, the first sealing ring 1 is provided with a first suction cup 101 and a first connecting ring 102, and The middle position of the first sealing ring 1 is provided with a first through hole 103, the second sealing ring 3 is provided with a second suction cup 301 and a second connecting ring 302, and the middle position of the second sealing ring 3 is provided with a second through hole 303; the inner wall of the first connecting ring 102 is provided with internal threads, and the outer wall of the second connecting ring 302 is provided with external threads, and the first conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com