Composite sheet

A composite sheet and release sheet technology, which is applied in the manufacture of synthetic resin layered products, electrical components, and printed circuits, can solve problems such as poor thermal conductivity, and achieve excellent thermal conductivity and excellent cushioning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

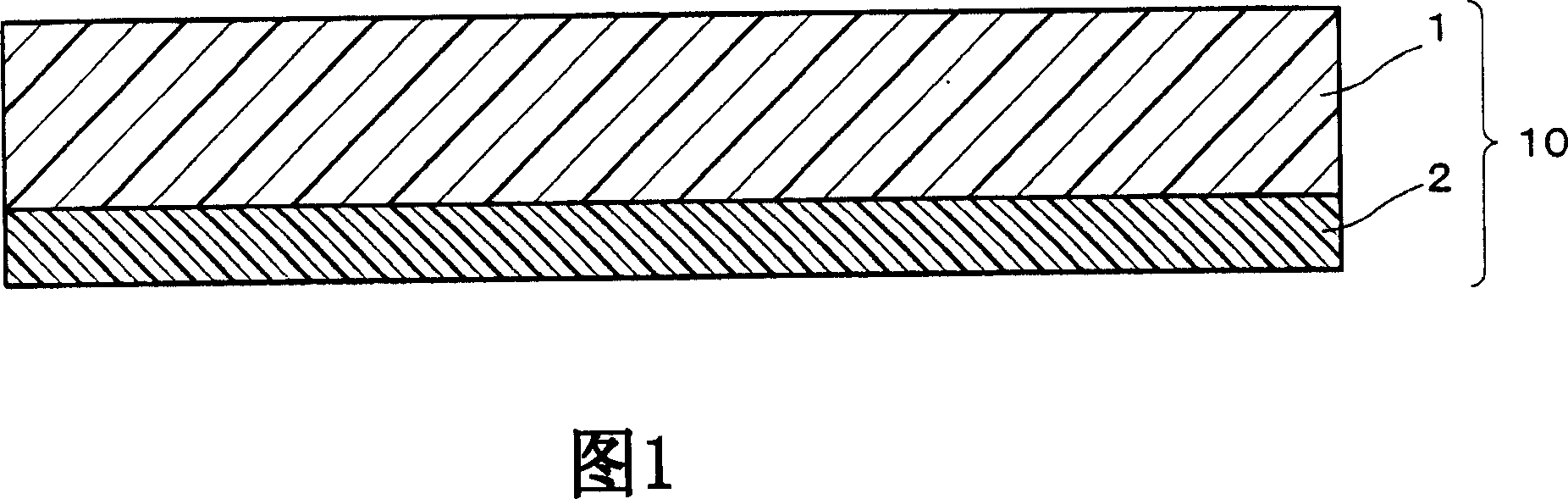

[0029] Silicone gel paste (X-32-2129 manufactured by Shin-Etsu Silicon Co., Ltd.) is applied to a PTFE film after one main surface has been bonded, that is, a bonded PTFE film (No. .901, thickness: 25μm) on the bonded surface. Afterwards, heat at 120° C. for 1 hour to solidify the applied silicone gel paste to form a silicone gel sheet with a thickness of 200 μm to obtain a composite sheet with a total thickness of 225 μm. In this example, the above-mentioned PTFE film corresponds to the release sheet.

Embodiment 2

[0031] In addition to using PTFE-impregnated glass cloth that has been bonded on one main surface, bonded PTFE-impregnated glass cloth (Nitto Denko Co. Except for No. 901 manufactured by Japan Co., Ltd., a composite sheet having a total thickness of 250 μm was obtained in the same manner as in Example 1 above. In this example, the above-mentioned PTFE-impregnated glass cloth corresponds to the release sheet.

Embodiment 3

[0033] Except using the PTFE porous membrane (NTF1026 manufactured by Nitto Denko, thickness: 25 μm) to replace the bonded PTFE membrane (No.901 manufactured by Nitto Denko), all the other operations are the same as in the above-mentioned embodiment 1 to obtain a total thickness of 225 μm. Composite sheet. In this example, the above-mentioned porous PTFE membrane corresponds to a release sheet.

[0034]Any one of the silicone gel sheets in the composite sheets in the above-mentioned Examples 1 to 3 has an adhesive force to glass specified in JIS A5759 within the range of 35 g / cm or more, and the JIS- A hardness is in the range of less than 10. In addition, the penetrations specified in JIS K 2207 are all in the range of 150 to 20 mm / 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com