Highly-closed fireproof check valve

A check valve, airtight technology, applied in the direction of control valve, safety valve, balance valve, etc., can solve the problems of fire protection delay, unfavorable normal smoke exhaust, etc., and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

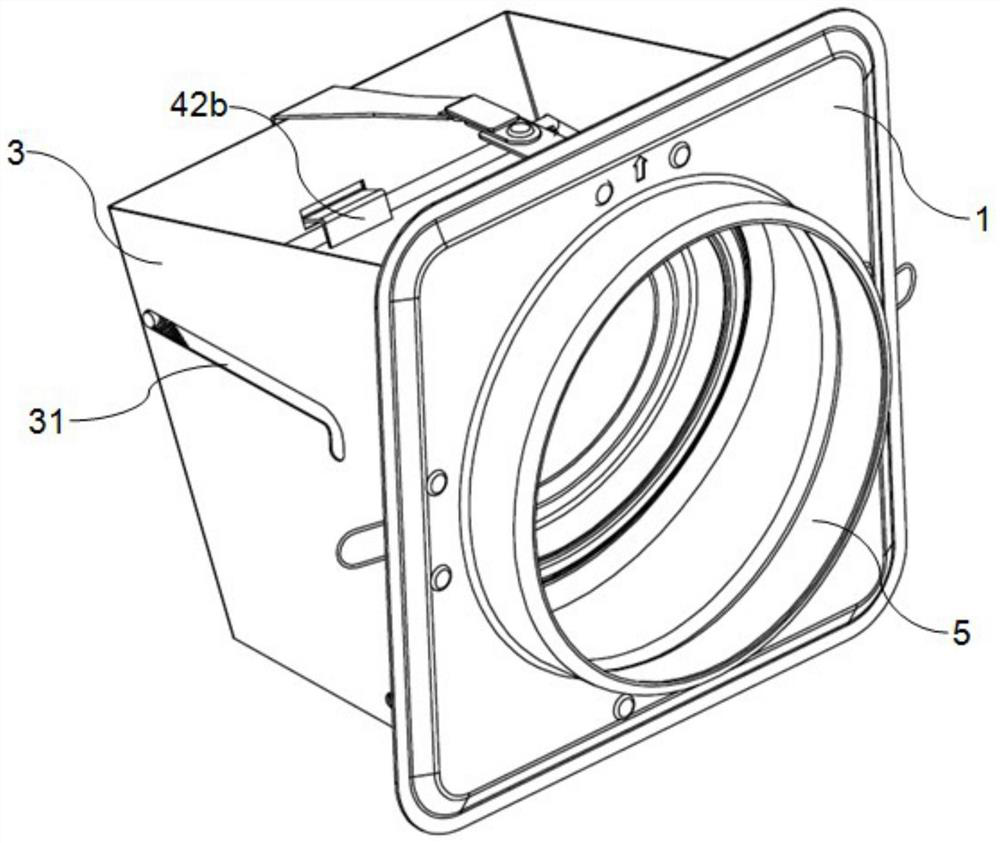

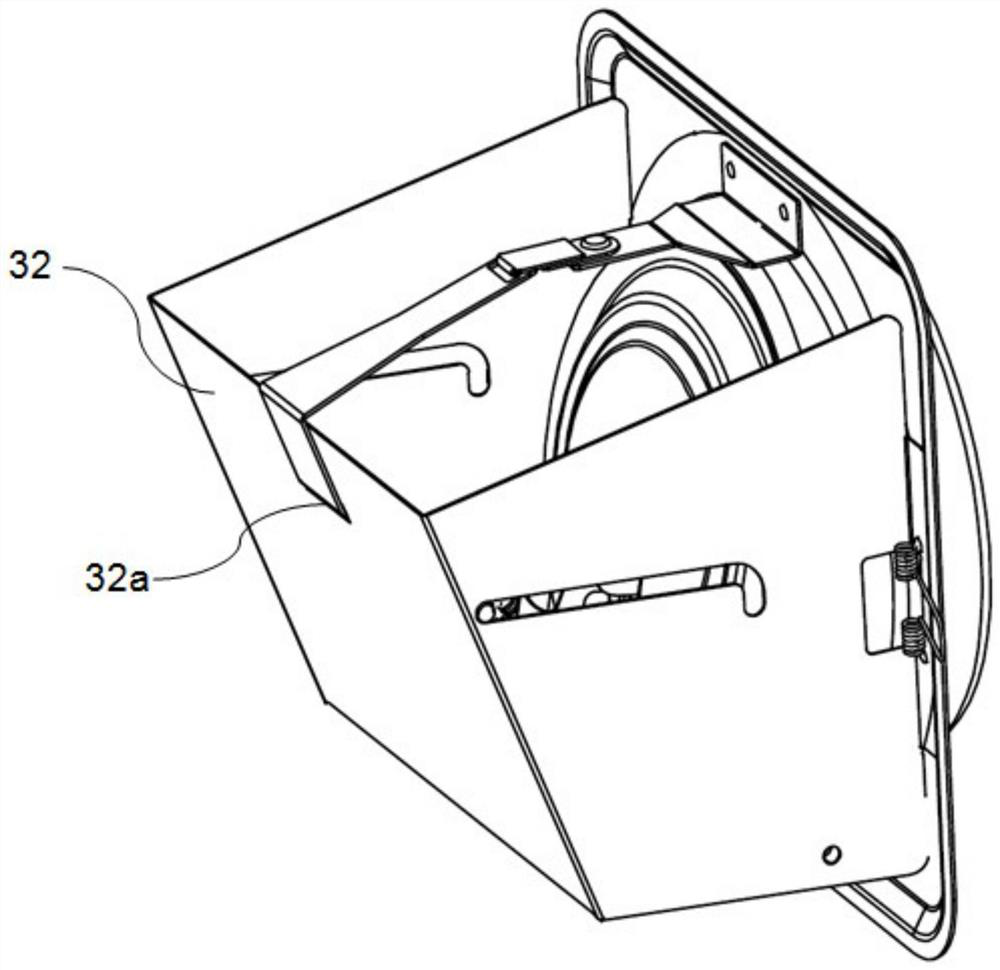

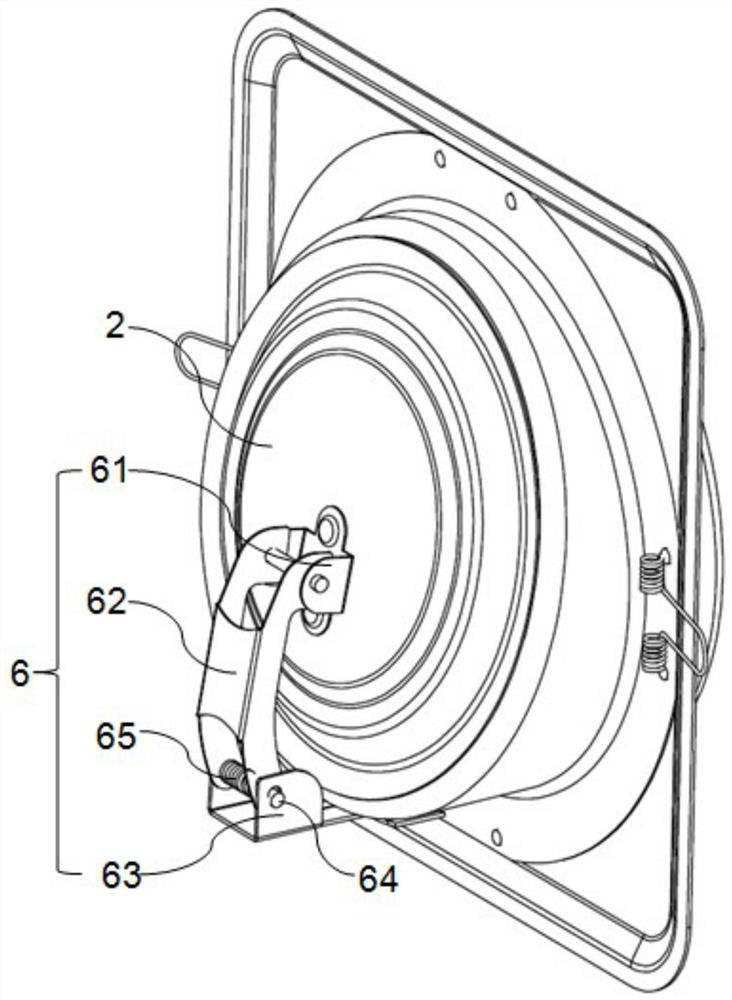

[0027] like Figure 1 to Figure 6 As shown, the embodiment of the present invention discloses a high airtight fireproof check valve, including a valve body 1, a valve plate 2, a deflector 3 and a fusing closure assembly 4. The materials of these parts can be 304 stainless steel to improve safety. coefficient. Both sides of the valve body 1 are respectively provided with an air inlet and an air outlet. The valve plate 2 is covered at the air outlet. The valve plate 2 always has a tendency to close. The upper end of the valve plate 2 is inclined towards the direction close to the valve body 1 , so that the valve plate 2 can cover the air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com