Gas mixer applicable to low-pressure gas

A gas mixing device, low-pressure gas technology, applied in the directions of gas and gas/vapor mixing, mixer, mixing method, etc., can solve the problems of increased fluid resistance, high production cost, increased investment, etc., to solve the mixing problem, Low resistance and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

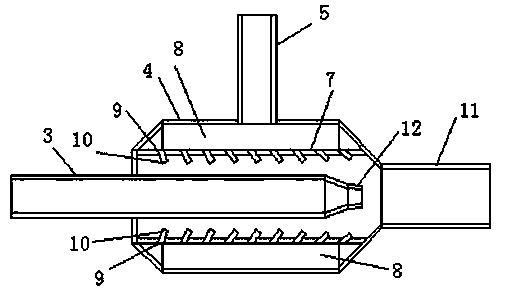

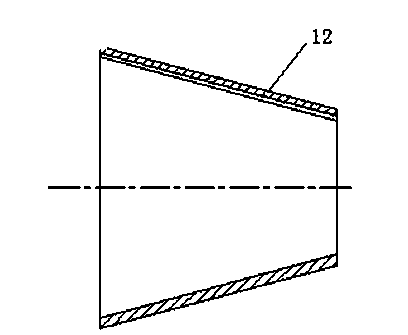

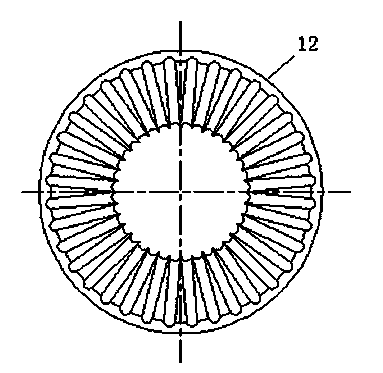

[0041] A gas mixing device suitable for low-pressure gas, comprising a jet mixer 1, a fan 2, the mixed gas outlet of the jet mixer 1 is connected to the inlet of the fan 2, and the jet mixer 1 includes a Venturi jet tube 3, a mixer The casing 4, the nozzle part of the Venturi jet tube 3 is located in the mixer 1, and the mixer casing 4 is provided with an air inlet pipe 5 at an angle of 90 degrees to the Venturi jet tube 3.

Embodiment 2

[0043] A gas mixing device suitable for low-pressure gas, comprising a jet mixer 1, a fan 2, the mixed gas outlet of the jet mixer 1 is connected to the inlet of the fan 2, and the jet mixer 1 includes a Venturi jet tube 3, a mixer The casing 4, the nozzle part of the Venturi jet tube 3 is located in the mixer 1, and the mixer casing 4 is provided with an air inlet pipe 5 at an angle of 90 degrees to the Venturi jet tube 3.

[0044] The Venturi jet tube 3 is a low-pressure gas inlet tube.

Embodiment 3

[0046]A gas mixing device suitable for low-pressure gas, comprising a jet mixer 1, a fan 2, the mixed gas outlet of the jet mixer 1 is connected to the inlet of the fan 2, and the jet mixer 1 includes a Venturi jet tube 3, a mixer The casing 4, the nozzle part of the Venturi jet tube 3 is located in the mixer 1, and the mixer casing 4 is provided with an air inlet pipe 5 at an angle of 90 degrees to the Venturi jet tube 3.

[0047] The Venturi jet tube 3 is a low-pressure gas inlet tube.

[0048] A flow meter 6 and a regulating valve are arranged at the inlet of the Venturi jet pipe 3 , and a flow meter 6 is arranged at the inlet of the fan 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com