A rotary hearth furnace screw discharge device

A technology of spiral discharge and rotary hearth furnace, which is applied in the direction of furnaces, furnace types, hearth type furnaces, etc., can solve the problems of blade wear, rotary hearth furnace pellet breaking, pulverization, etc., to reduce the stress on blades and slow down The effect of blade wear speed and prolonging the service life of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

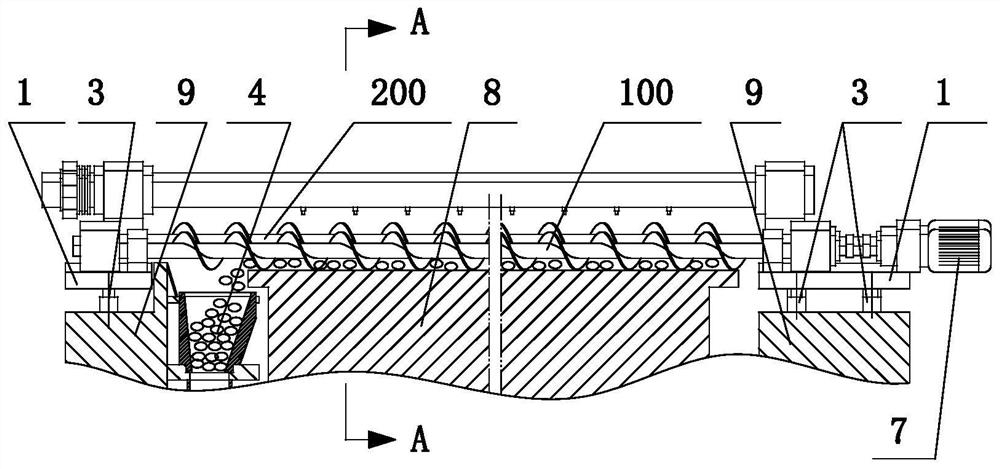

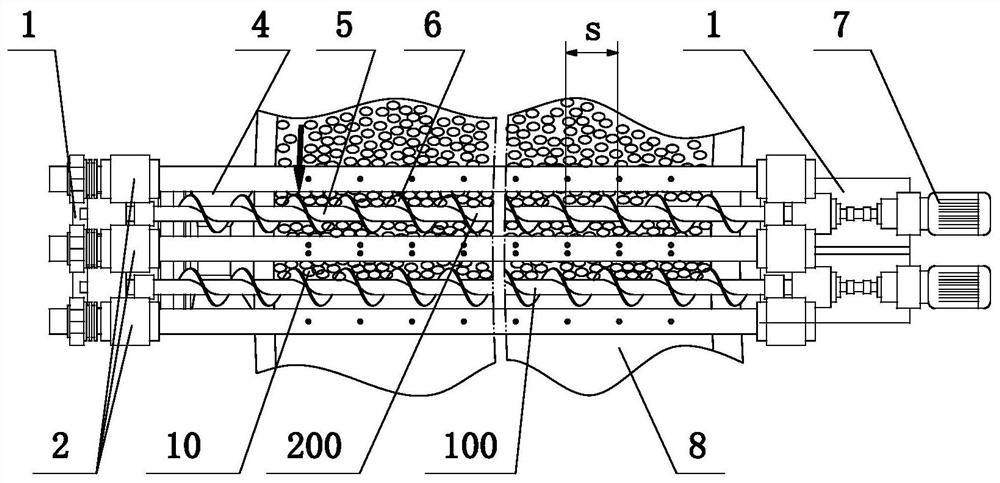

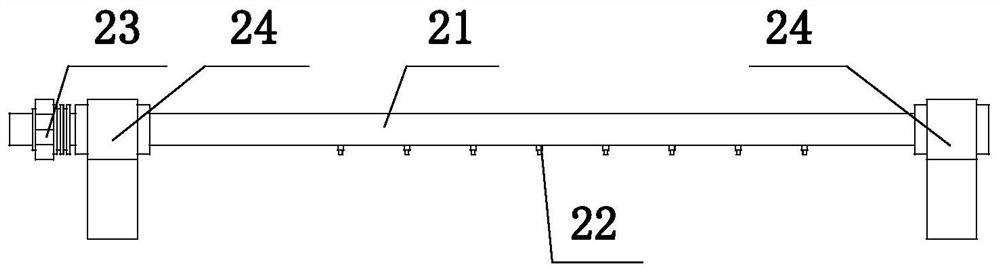

[0024] like Figures 1 to 4 As shown, the rotary hearth furnace screw discharging device according to an embodiment of the present invention includes a first screw discharging machine 100 arranged above the hearth 8 of the rotary hearth furnace, and also includes a first screw discharging machine 100 arranged on the first screw discharging machine 100. The second screw feeder 200 on the inlet side of the 2000 , the two ends of the first screw feeder 100 and the second screw feeder 200 are respectively arranged on the lifting platform 1 . The lifting platform 1 is lifted and lowered by the hydraulic cylinder 3 fixed on the system base 9 to compensate for the wear of the blades 6 of the first screw feeder 100 and the second screw feeder 200 . Preferably, each of the first screw feeder 100 and the second screw feeder 200 is driven by a separate mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com