A method for repairing hydraulic columns of waste mining machinery and equipment parts

A technology of hydraulic columns and mechanical equipment, applied in heat treatment equipment, furnaces, manufacturing tools, etc., can solve problems such as damaged parts and insufficient repair of equipment parts, and achieve the effects of prolonging service life, dense tissue, and rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] A method for repairing a hydraulic column of waste mining machinery and equipment, comprising the following steps:

[0022] 1) Determine the damage area of the hydraulic column, measure the size of the surface of the hydraulic column, and inspect the curvature at the same time to obtain the wear thickness D and runout M;

[0023] 2) Whether the wear thickness d in the judgment step 1) exceeds 45% of the wear thickness D of the original chrome-plated layer, enter the runout judgment after the wear thickness judgment is completed, and judge whether the absolute value of the difference between the runout m and the original runout M is Greater than 0.4mm;

[0024] 3) When the wear thickness d>45% of the original chrome-plated wear thickness D, and the absolute value of the difference between the run-out m and the original run-out M≤0.4mm, enter step 4); when the wear thickness d≤45% of the worn thickness D of the original chrome plating layer, and the absolute value of t...

experiment example

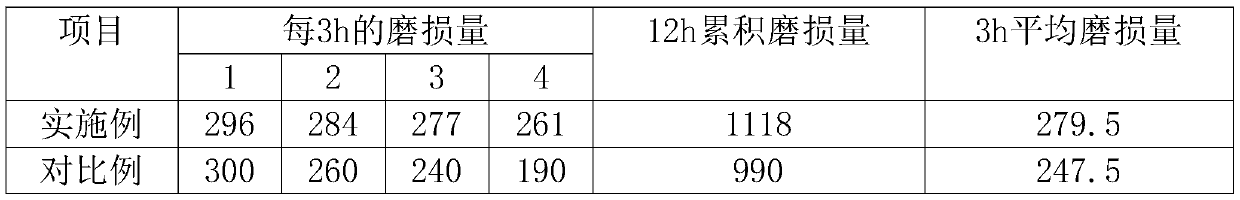

[0029] One, make following comparison test for the wear amount of the embodiment of the present invention relative to the prior art, as shown in table 1:

[0030]

[0031]As can be seen from the above table, the wear amount of the present invention is 247.5×10 -5 g relative to the wear amount of the prior art 279.5×10 -5 g decreased by 11.45%.

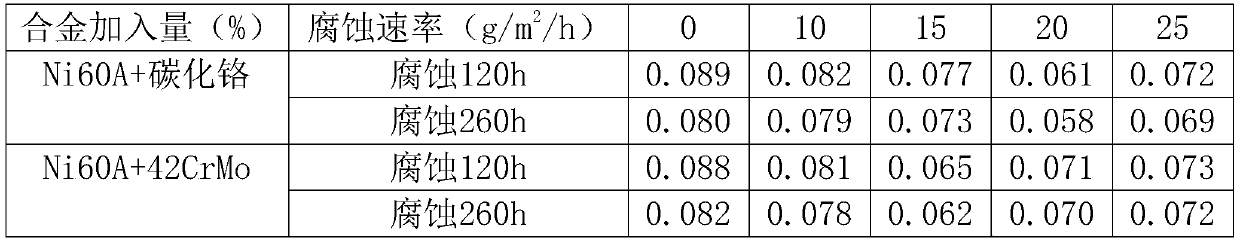

[0032] 2. The addition of Ni60A+chromium carbide alloy powder or Ni60A+42CrMo alloy powder to the corrosion resistance of the cladding layer is shown in Table 2:

[0033]

[0034] As can be seen from Table 2, when the addition of Ni60A+chromium carbide alloy powder of the present invention is 20%, the corrosion rate of the cladding layer is the smallest, and when the addition of Ni60A+42CrMo alloy powder is 15%, the corrosion rate of the cladding layer is the smallest.

[0035] 3. The hardness of the surfacing layer under different surfacing process parameters is shown in Table 3:

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com