Automatic sampler and automatic sampling method

An automatic sampler and automatic sampling technology, applied in the direction of sampling, sampling devices, instruments, etc., can solve the problems of sampling bottle homing, troublesome sampling quantity and concentration control, and inaccurateness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

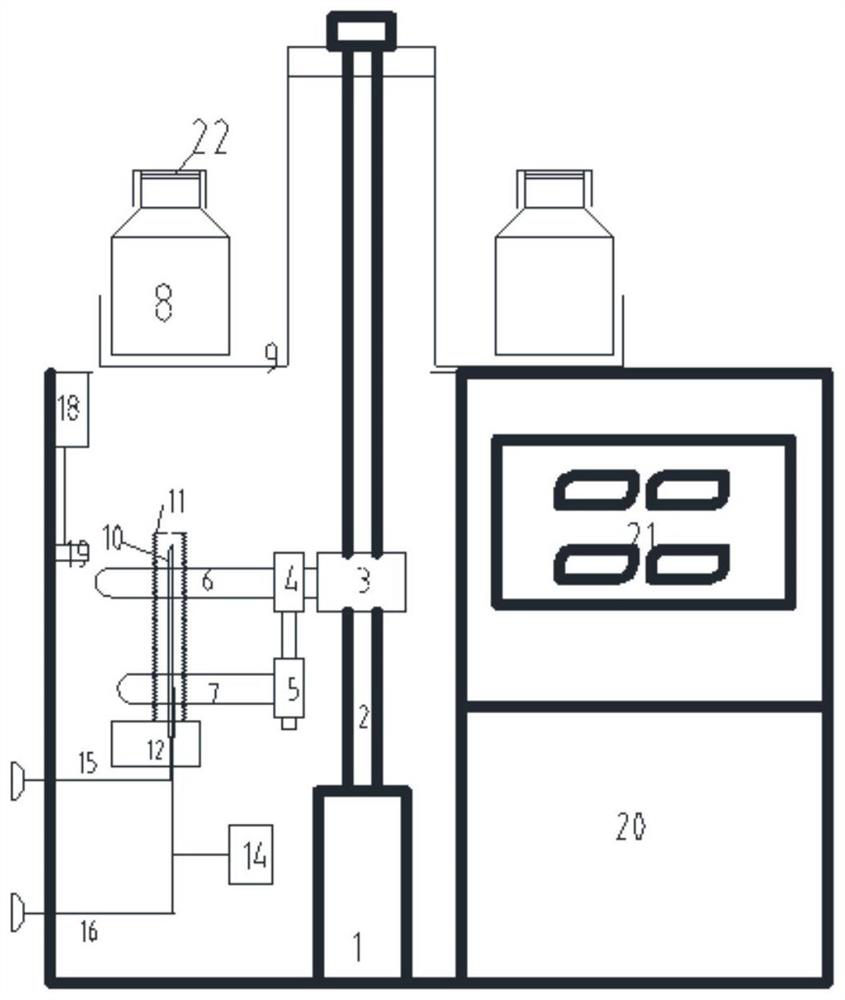

[0042] Such as figure 1 , Figure 4 Shown, a kind of autosampler, described autosampler comprises sampling bottle 8 and the tray 9 of bearing sampling bottle, has the breach 23 that can pass through for sampling bottle on the described tray, is provided with power in the described autosampler Device 1, the drive shaft 2 arranged on the power unit and the clamping device that can grip and vertically flip the sampling bottle, the clamping device is movably connected to the drive shaft, and can act on the power unit and the drive shaft Move up and down, the pin 10 that can be inserted into the sampling bottle is provided under the clamping device, the inside of the pin is hollow, and the bottom of the pin is provided with two pipes, one of which is connected to the water inlet device 15, A water outlet device 16 is connected, and a vacuum generator 14 is installed on the water outlet device; the automatic sampler is also provided with a control module, and the control module inc...

Embodiment 2

[0070] like figure 2 , Figure 4 Shown, a kind of autosampler, described autosampler comprises sampling bottle 8 and the tray 9 of bearing sampling bottle, has the breach 23 that can pass through for sampling bottle on the described tray, is provided with power in the described autosampler Device 1, the drive shaft 2 arranged on the power unit and the clamping device that can grip and vertically flip the sampling bottle, the clamping device is movably connected to the drive shaft, and can act on the power unit and the drive shaft Move up and down, the pin 10 that can be inserted into the sampling bottle is provided under the clamping device, the inside of the pin is hollow, and the bottom of the pin is provided with two pipes, one of which is connected to the water inlet device 15, A water outlet device 16 is connected, and a vacuum generator 14 is installed on the water outlet device; the automatic sampler is also provided with a control module, and the control module inclu...

Embodiment 3

[0100] like image 3 , Figure 4 Shown, a kind of autosampler, described autosampler comprises sampling bottle 8 and the tray 9 of bearing sampling bottle, has the breach 23 that can pass through for sampling bottle on the described tray, is provided with power in the described autosampler Device 1, the drive shaft 2 arranged on the power unit and the clamping device that can grip and vertically flip the sampling bottle, the clamping device is movably connected to the drive shaft, and can act on the power unit and the drive shaft Move up and down, the pin 10 that can be inserted into the sampling bottle is provided under the clamping device, the inside of the pin is hollow, and the bottom of the pin is provided with two pipes, one of which is connected to the water inlet device 15, A water outlet device 16 is connected, and a vacuum generator 14 is installed on the water outlet device; the automatic sampler is also provided with a control module, and the control module includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com