A motherboard testing device

A technology for testing devices and motherboards, which is applied in error detection/correction, faulty computer hardware, and instrument detection, and can solve problems such as fatigue, heavy workload of operators, and low plug-in efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

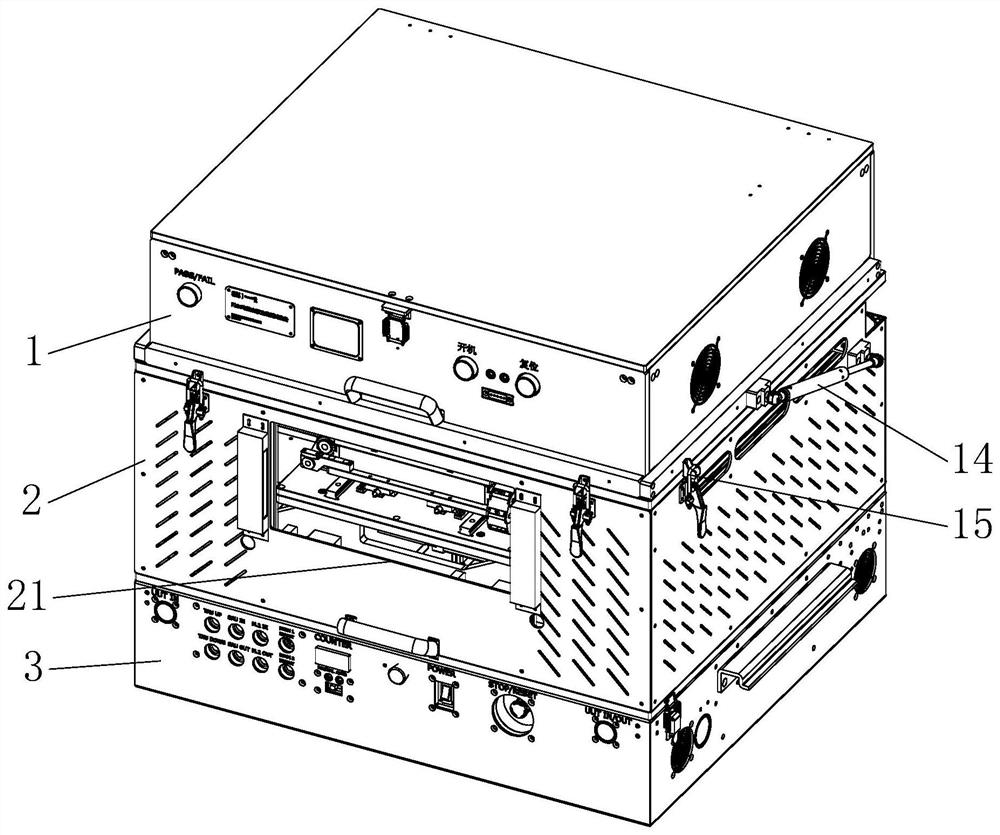

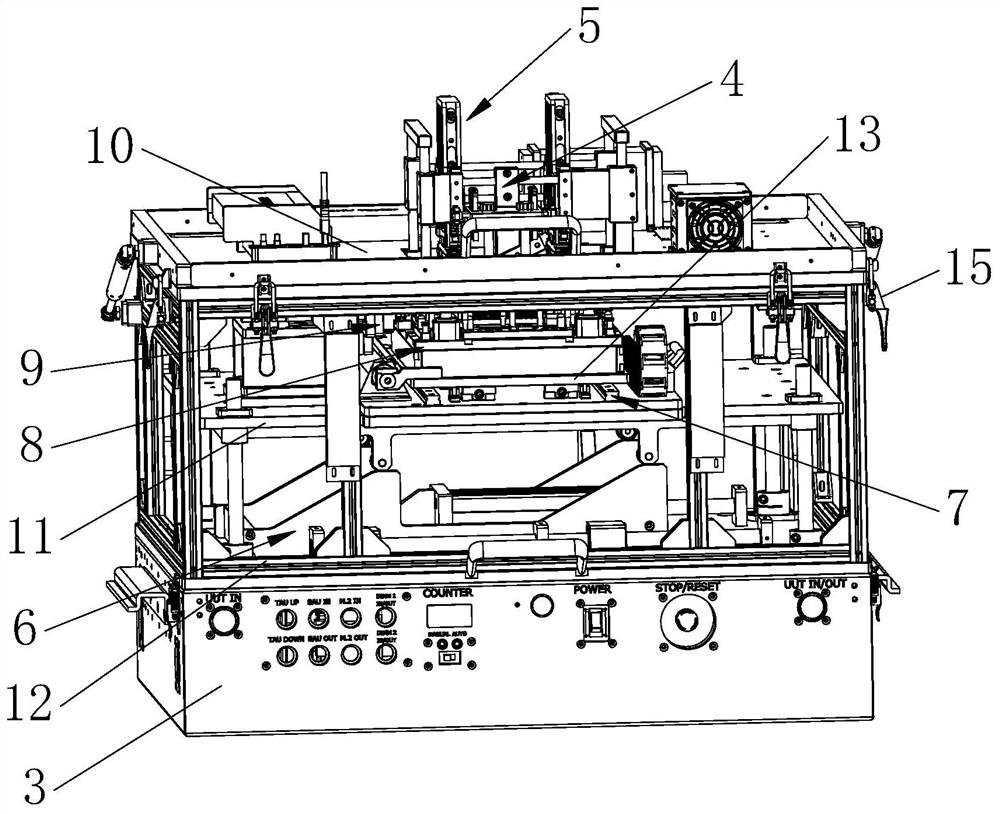

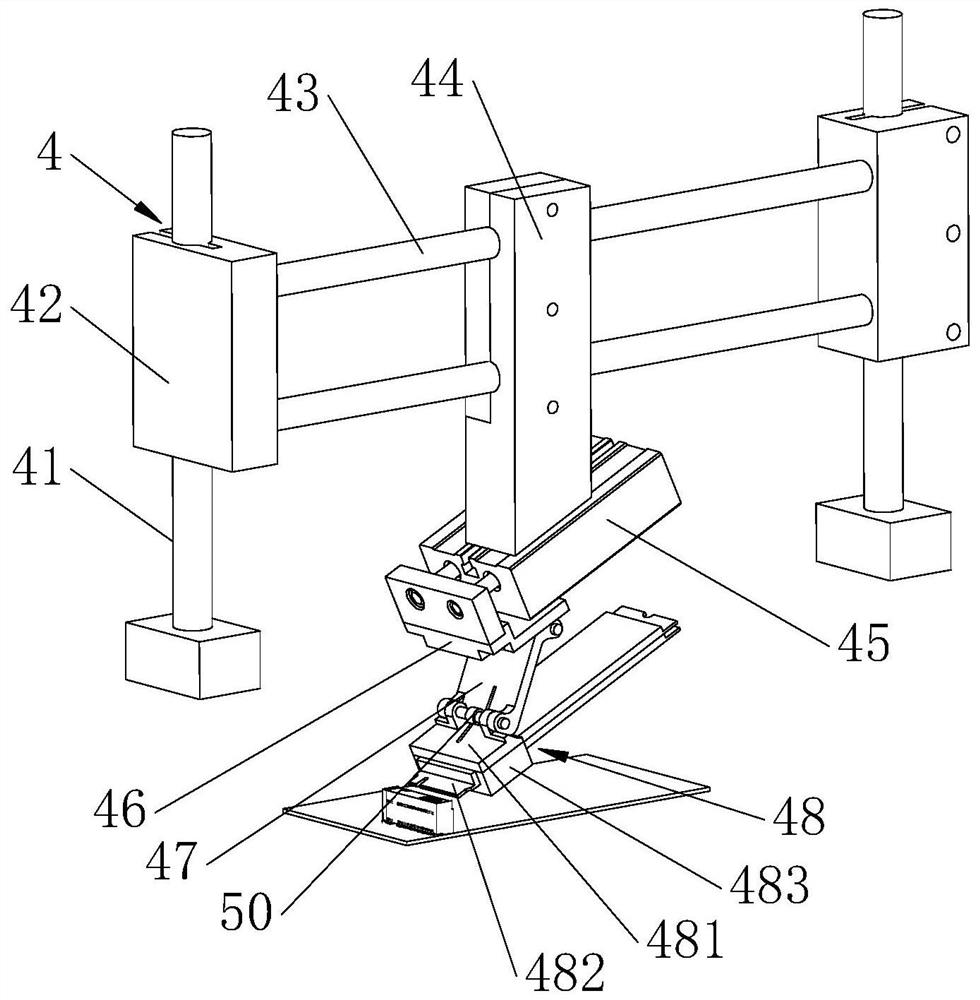

[0033] Below in conjunction with accompanying drawing, the present invention will be further described, as Figure 1-10 As shown, the present invention includes a chassis 2, a machine cover 1 hinged on the top of the chassis 2, a power supply module 3 arranged at the bottom of the chassis 2, and a top plate 10, which is arranged on the top plate 10 for inserting the board into the mainboard M.2 interface and Board card testing mechanism 4 for deriving test signals, a memory stick testing mechanism 5 arranged on the top board 10 for inserting the memory stick into the memory stick slot of the mainboard and exporting test signals, and a middle board slidingly connected in the case 2 along the Z-axis direction 11. Bottom plate 12, a lifting mechanism set on the bottom plate 12 for driving the middle plate 11 to slide, 6, a carrier plate 13 slidably connected to the middle plate 11 along the Y-axis direction, set on the middle plate 11 to drive the carrier plate 13 Sliding board f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com