Air disinfection and sterilization negative-pressure partition screen

A negative pressure isolation and air disinfection technology, applied in the field of isolation screens, can solve the problems of single function, high cost, poor ventilation effect, etc., and achieve the effect of stable and reliable structure, easy disassembly and maintenance, and neat appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

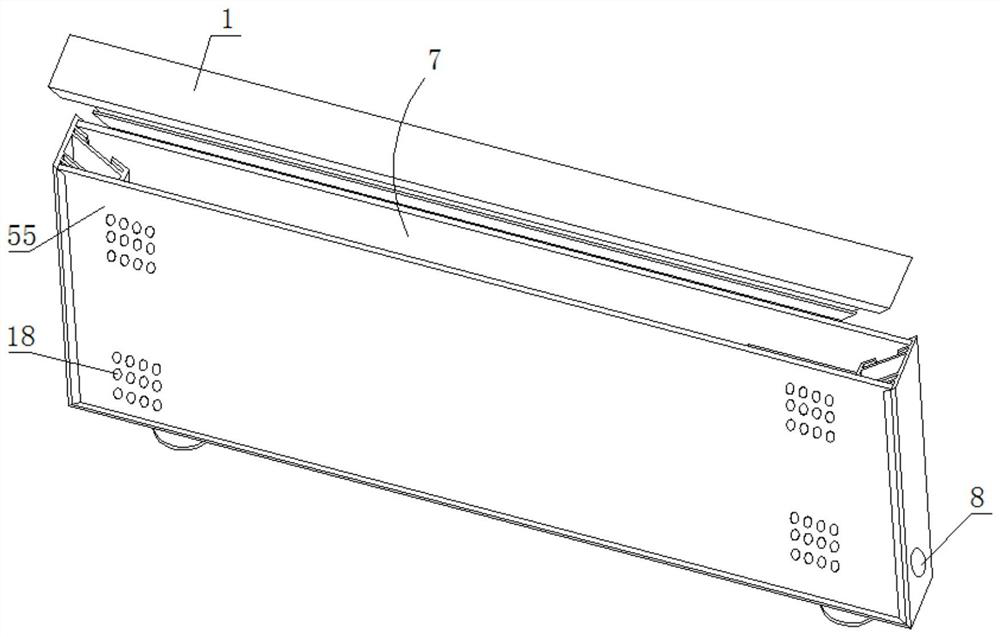

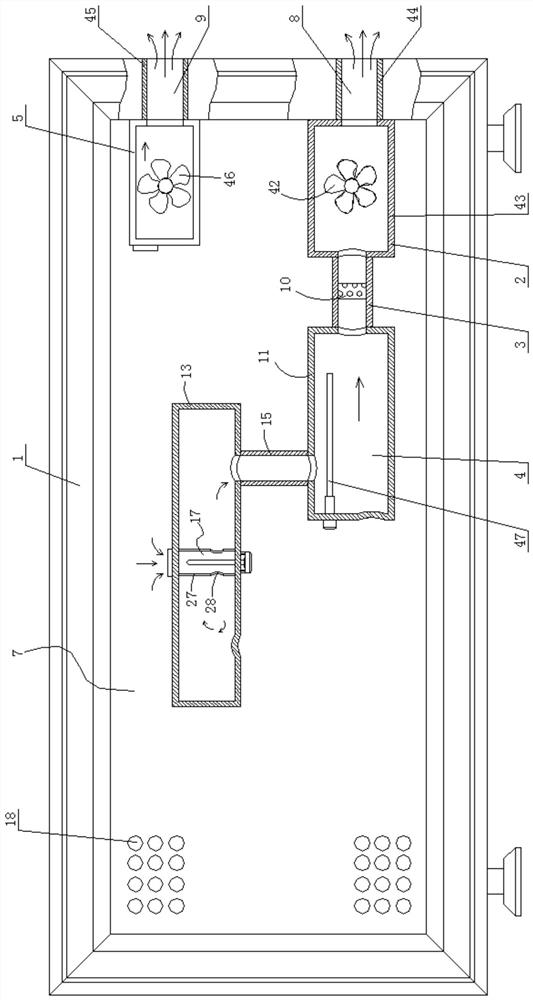

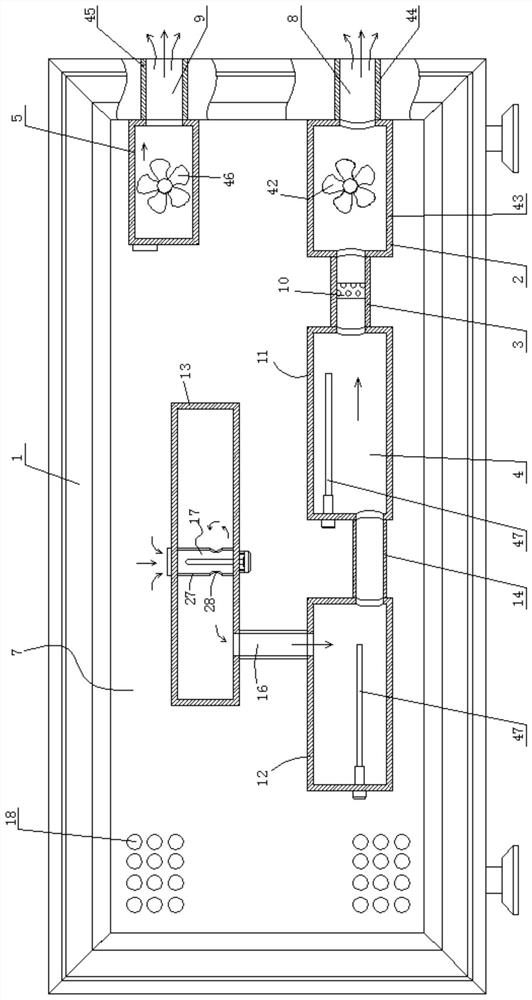

[0047] Specific implementation mode one: refer to Figure 1-14 Describe this embodiment, a kind of air disinfection and sterilization negative pressure isolation screen of this embodiment is characterized in that: it comprises frame 1, exhaust box 2, filter pipe 3 and disinfection box 4, and the front and back of described frame 1 is installed with isolation plate 55, the isolation plate 55 and the frame 1 form an accommodation cavity 7, the exhaust box 2, the filter pipe 3 and the disinfection box 4 are arranged and installed inside the accommodation cavity 7, and the side wall of the frame 1 is provided with an exhaust port 8, and the exhaust One end of the bellows 2 communicates with the exhaust outlet 8, the other end of the exhaust box 2 communicates with the filter tube 3, the other end of the filter tube 3 communicates with the disinfection box 4, and the isolation plate 55 is processed with a plurality of valves communicated with the accommodation chamber 7. The air en...

specific Embodiment approach 2

[0051] Specific implementation mode two: refer to Figure 1-14 Describe this embodiment, a negative pressure isolation screen for air disinfection and sterilization in this embodiment, a filter 10 is installed in the filter tube 3, and the filter 10 is activated carbon. In this way, a filter 10 is arranged in the filter tube 3, and the filter 10 is a filter box, and activated carbon is stored in the filter box, and the filter box is installed in the filter tank 3 in a plug-in / plug-in manner, and is adsorbed under the action of the activated carbon. The peculiar smell in the air is eliminated, and substances such as formaldehyde are eliminated. The filter 10 can filter impurities and peculiar smells in the air, provide users with safe, reliable and fresh air, and create a refreshing atmosphere.

specific Embodiment approach 3

[0052] Specific implementation mode three: refer to Figure 1-14 Illustrate this embodiment, a kind of air disinfection and sterilization negative pressure isolation screen of this embodiment, described disinfection box 4 comprises ultraviolet disinfection box 11 and infrared disinfection box 13, and one end of described ultraviolet disinfection box 11 is connected with exhaust by filter pipe 3 Case 2 is communicated, and the other end of ultraviolet sterilizing box 11 is communicated with infrared sterilizing box 13 by second connecting pipe 15, and infrared generator 17 is installed in infrared sterilizing box 13, and ultraviolet ray generating tube 47 is installed in ultraviolet sterilizing box 11. So set, the air that enters the accommodation cavity 7 through the air inlet hole 18 first enters the infrared disinfection box 13 to realize high-temperature sterilization, and then enters the ultraviolet disinfection box 11, and the ultraviolet light generation tube 47 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com