Heating equipment capable of adjusting steam flow direction

A technology for heating equipment and steam, which is applied to cooking utensils, steam cooking utensils, household utensils, etc., can solve the problems of unfavorable surface heating of food to be grilled, limitation of activity range, etc., and achieve the effect of uniform effect and enhanced effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

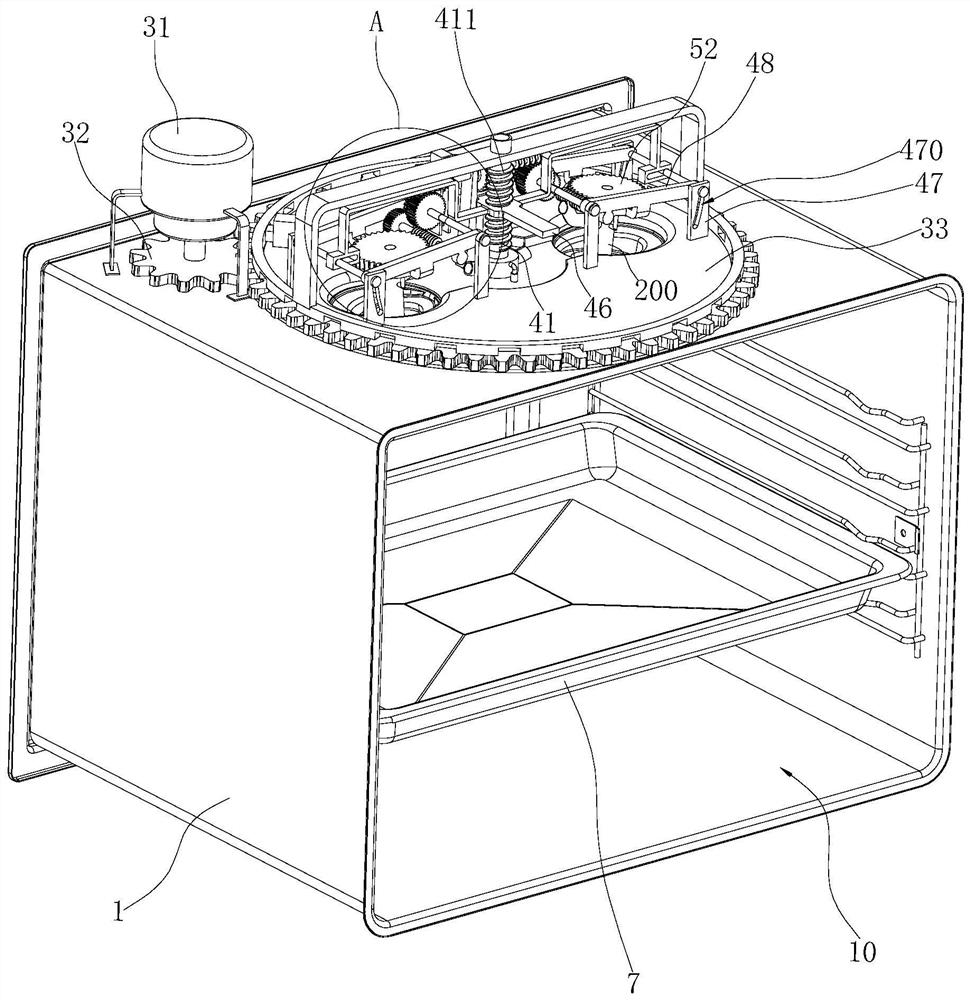

[0068] Such as Figure 1~3 As shown, this embodiment provides a heating device with adjustable steam flow direction, specifically a steam box with adjustable steam flow direction. The steamer includes:

[0069] The inner tank 1 is formed with a chamber 10, the top of the chamber 10 has an opening 100 formed around the central axis of the chamber 10, and the tray 7 for holding food is placed in the chamber 10; the structure of the inner tank 1 is shown in Figure 7 shown;

[0070] A steam generating device (not shown in the figure) generates steam entering the chamber 10; the steam generating device has a steam delivery pipe 5 for steam delivery to the inner bag chamber 10, and the outlet end of the steam delivery pipe 5 is located at Inside the inner tank chamber 10;

[0071] Two exhaust fans are respectively arranged on the left and right sides in the chamber 10. The exhaust fan has a rotating shaft 21 and a fan blade 22 rotating with the rotating shaft 21. The fan blade 2...

Embodiment 2

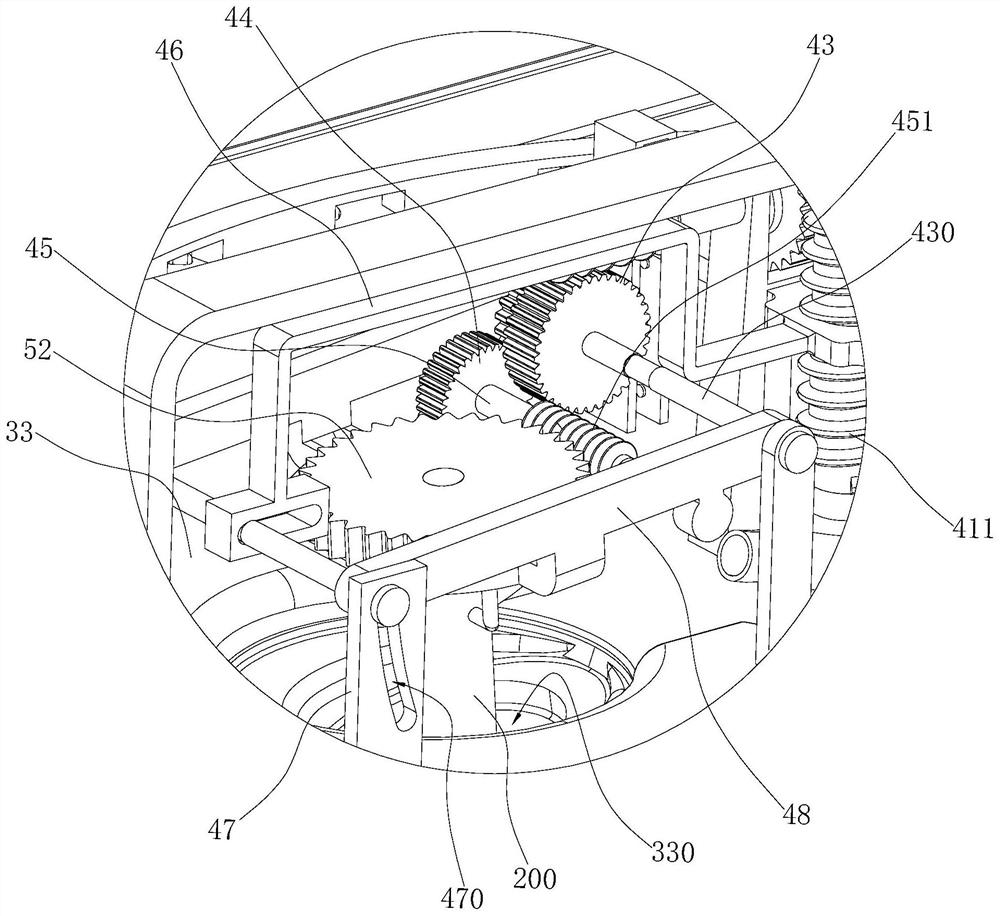

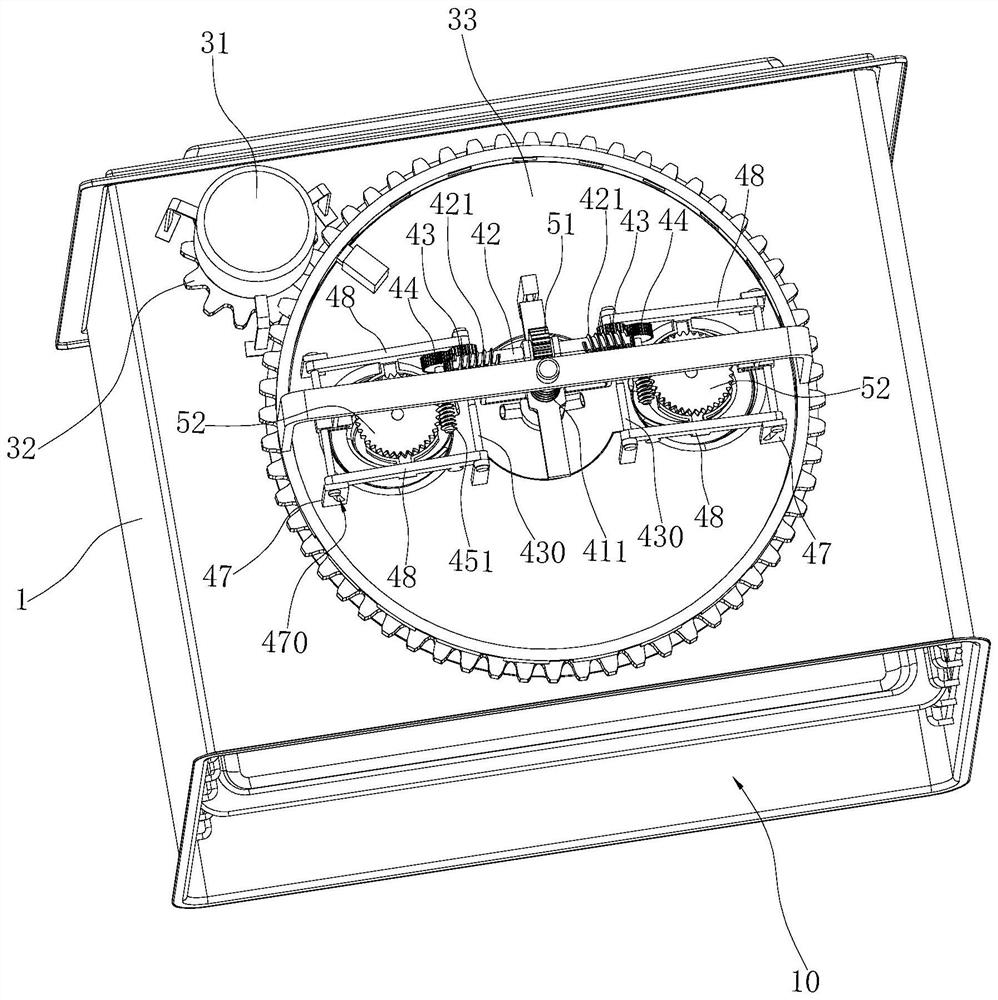

[0095] Such as Figure 8-11 As shown, the second embodiment provides another steam box that can adjust the direction of steam flow. The difference from the structure of the steam box in the first embodiment is that both the first driving mechanism and the second driving mechanism of the second embodiment are adjusted.

[0096] specifically;

[0097] The first drive mechanism includes:

[0098] The first motor 31' is arranged on the outside of the chamber 10 and is located on the top of the inner container 1;

[0099] The first driving gear 32' is connected with the transmission of the first motor 31';

[0100] The first driven gear 33' has a rotating hole 330' for the shaft 21 to pass through to enter the chamber 10, the first driven gear 33' is engaged with the first driving gear 32', and the first driven gear 33' is meshed with the first driving gear 32'. The opening 100 is adapted to make it move along the opening 100; wherein, the forming direction of the opening 100 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com