Oil stirring and skimming device for producing sesame oil

A technology of sesame oil and stirring chamber, which is applied in the direction of mixer with rotating stirring device, transportation and packaging, mixer accessories, etc., which can solve the problems of inability to handle oil and affect people's use, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

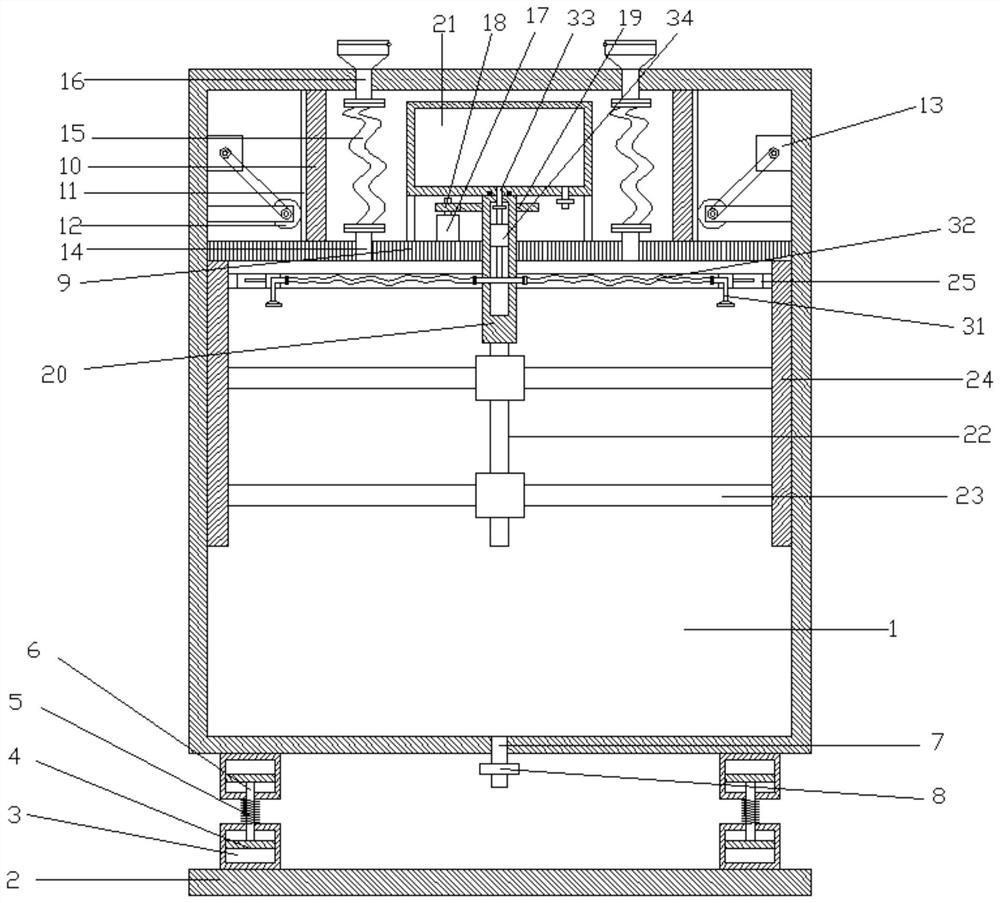

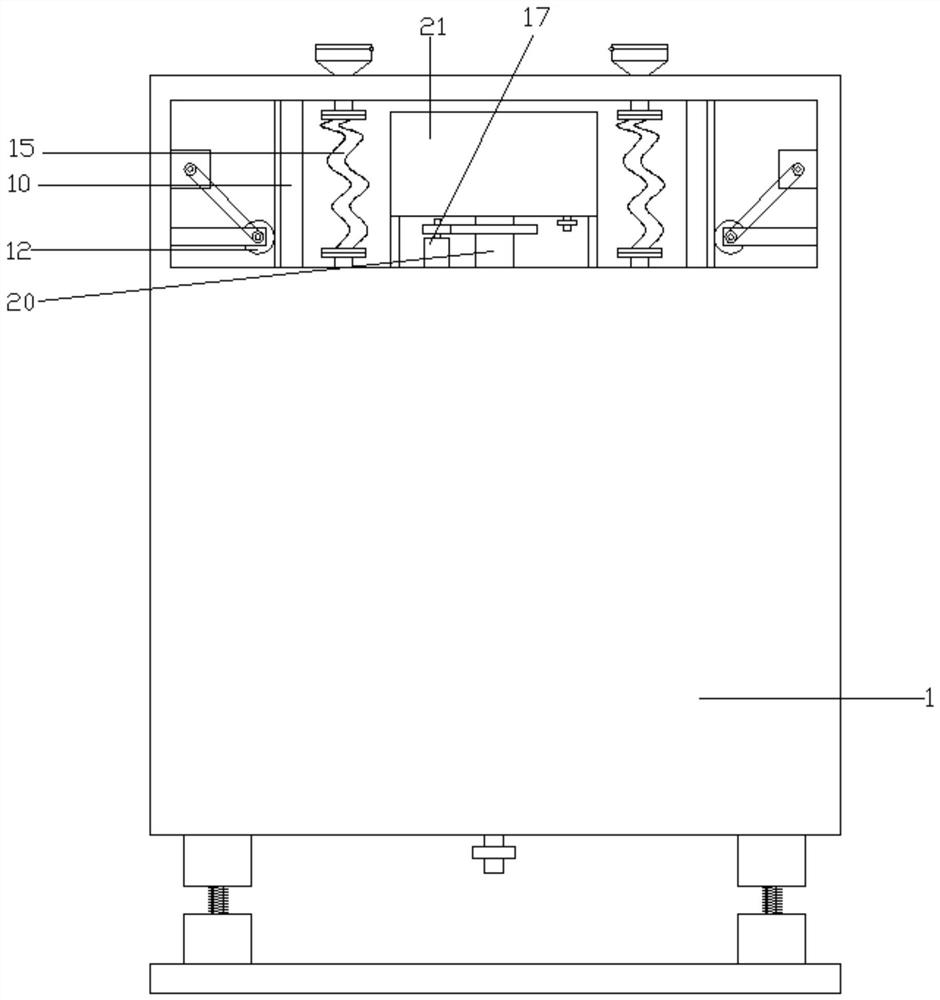

[0024] refer to Figure 1~4 , in an embodiment of the present invention, a kind of oil stirring and oil skimming device for producing sesame oil comprises a stirring chamber 1, an oil discharge pipe 7 is arranged in the middle part of the lower side of the stirring chamber 1, and a control valve 8 is installed on the oil discharge pipe 7, It is convenient to discharge the processed sesame oil.

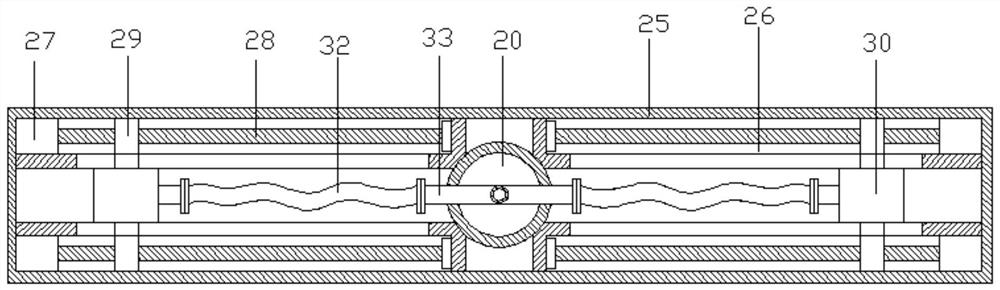

[0025] The upper end of the stirring chamber 1 is provided with a piston plate 9, the upper side of the piston plate 9 is fixedly equipped with a connecting plate 10 at the left and right ends, the outer side of the connecting plate 10 is fixedly installed with a rack 11, and the outer side of the rack 11 is meshed with a gear 12, and the gear 12 Connect with the inner wall of the stirring chamber 1 by the mounting piece and the connecting shaft, the connecting shaft on the front side of the gear 12 is connected with the first motor 13 by a belt, the first motor 13 is installed on the ...

Embodiment 2

[0029] The difference from Embodiment 1 is that a bottom plate 2 is installed on the lower side of the stirring chamber, and connecting seats 3 are symmetrically installed at the four corners of the lower side of the stirring chamber 1 and the four corners of the upper side of the bottom plate 2, and connecting blocks 4 are arranged inside the connecting seats 3 , the connecting blocks 4 are connected by connecting rods 5, and the connecting rods 5 between the connecting seats 3 are provided with springs 6, which can effectively reduce the vibration of the whole device, thus ensuring the stability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com