Online flushing device for drying rollers in cleaning section of annealing line

A technology of washing device and squeezing roller, which is applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of sticking iron sludge on the surface of the squeezing roller, and improve the quality of strip steel products. and productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

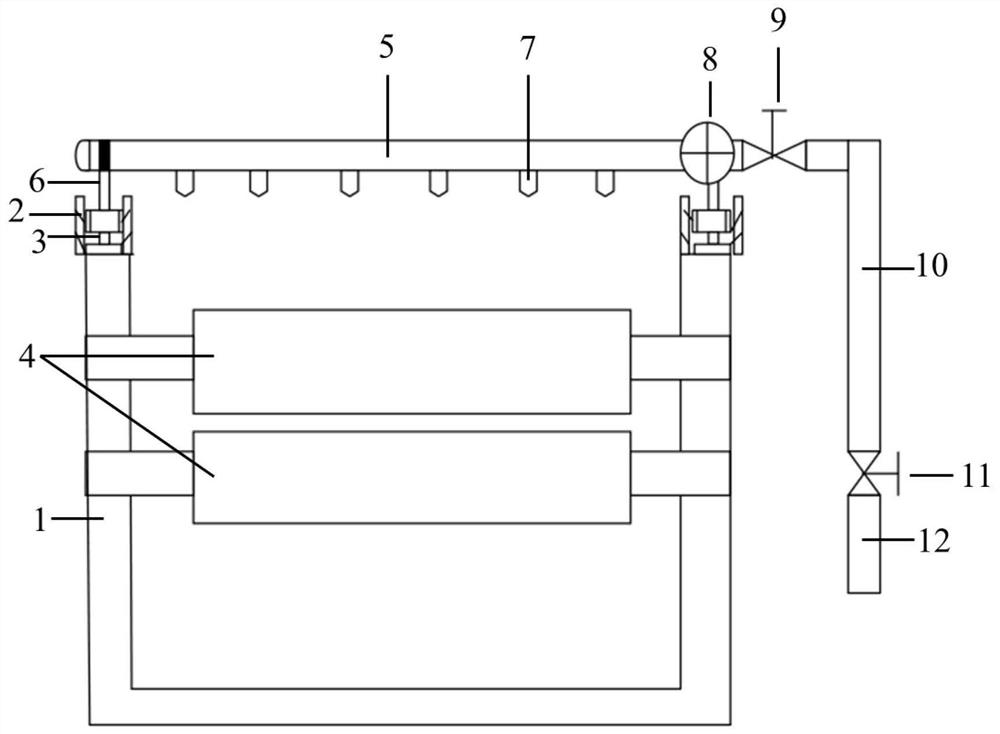

[0015] Such as figure 1 As shown, the present invention provides an online flushing device for squeezing rollers in the cleaning section of an annealing line, which includes a tank body 1, a moving guide groove 2 and a roller 3 are arranged on the upper end of the tank body 1, and a flushing roller 4 is arranged above the squeezing roller 4. Pipe 5, the two ends of the flushing pipe 5 are connected to the moving guide groove 2 through the nozzle base 6, and flushing nozzles 7 are distributed on the flushing pipe 5. Such structural design makes the flushing pipe 5 move back and forth along the moving guide groove 2, and can realize the online flushing of multiple pairs of squeezing rollers 4.

[0016] More specifically, an angle rotary regulating valve 8 is installed near the end of the flushing pipe 5 for adjusting the angle of flushing, which can improve the pair of squeeze rollers 4, especially the squeeze rollers located below in each pair. flushing effect.

[0017] More ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com