Cleaning method for energy mixing heat exchange unit with water quality detection function

A heat exchange unit and water quality detection technology, which is applied in the direction of flushing, water testing, and material inspection, can solve the problems of cumbersome work, reduced service life of heat exchange units, and inability to realize online dosing and cleaning, so as to solve cumbersome work and reduce The Effect of Washing Labor Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

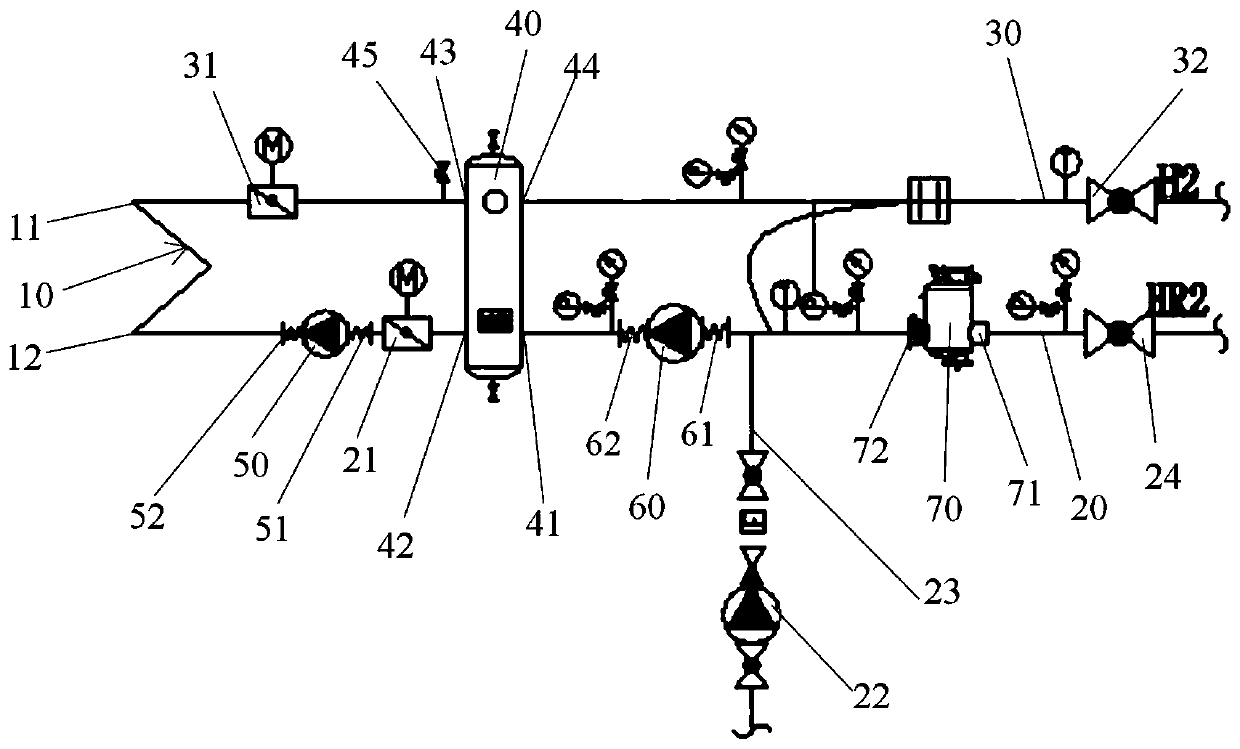

[0018] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

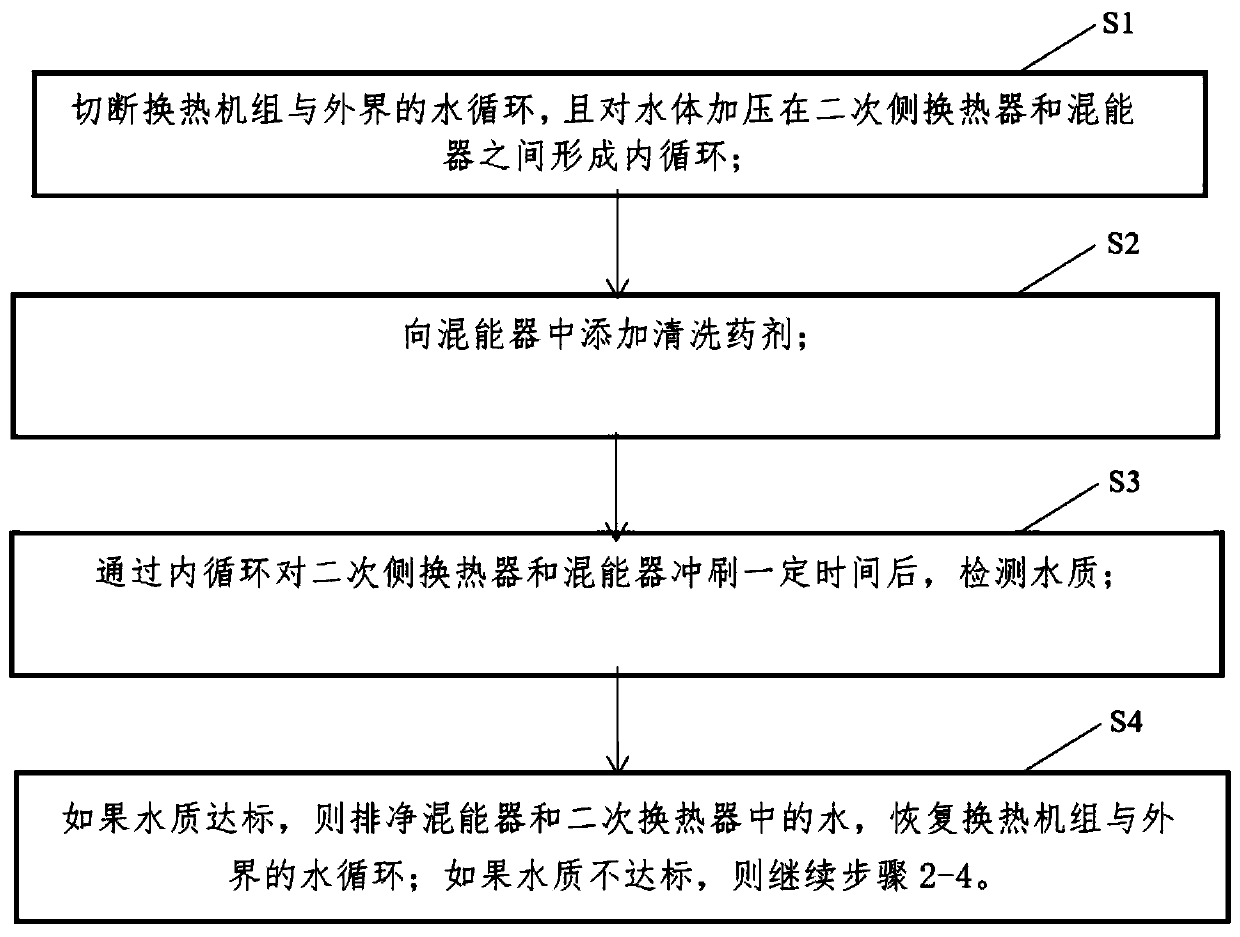

[0019] Such as figure 1 As shown, a cleaning method of a hybrid heat exchanger unit with water quality detection function, the hybrid heat exchanger unit includes a secondary side heat exchanger and a mixer connected in parallel with the secondary side heat exchanger, the cleaning The method includes the following steps:

[0020] S1: Cut off the water circulation between the heat exchange unit and the outside world, and pressurize the water body to form an internal circulation between the secondary side heat exchanger and the mixer;

[0021] S2: Add cleaning agent to the mixer;

[0022] S3: After flushing the secondary side heat exchanger and mixer for a certain period of time through internal circulation, test the water quality;

[0023] S4: If the water quality meets the standard, drain the water in the mixer and the secondary heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com