Automobile rear axle assembly with adjusting arm convenient to disassemble, assemble and adjust

An automobile rear axle and adjusting arm technology, which is applied in the field of automobile rear axle assembly, can solve the problems of high maintenance cost, non-adjustable adjustment arm installation clearance angle, inconvenient disassembly and assembly, etc., to increase the adjustment range, reduce production processes and costs , the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

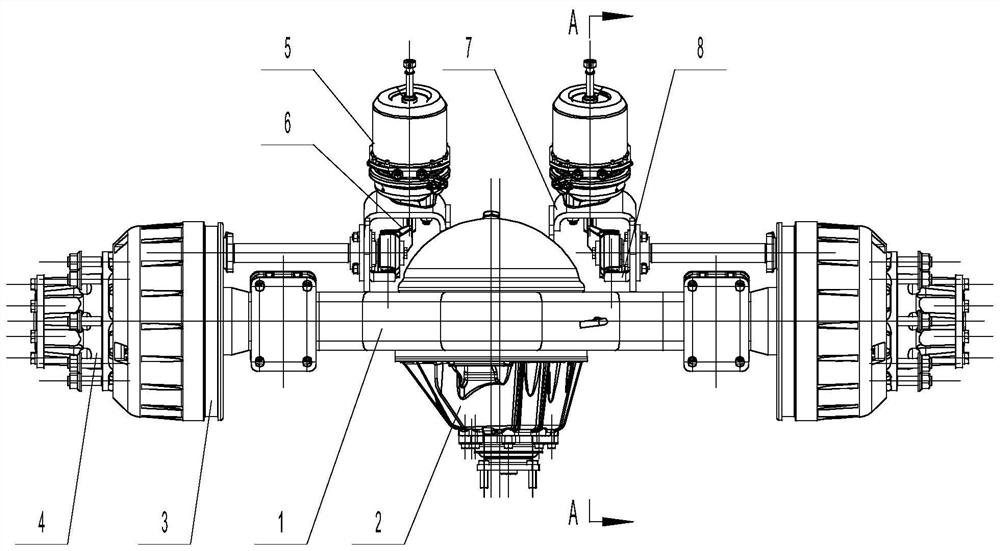

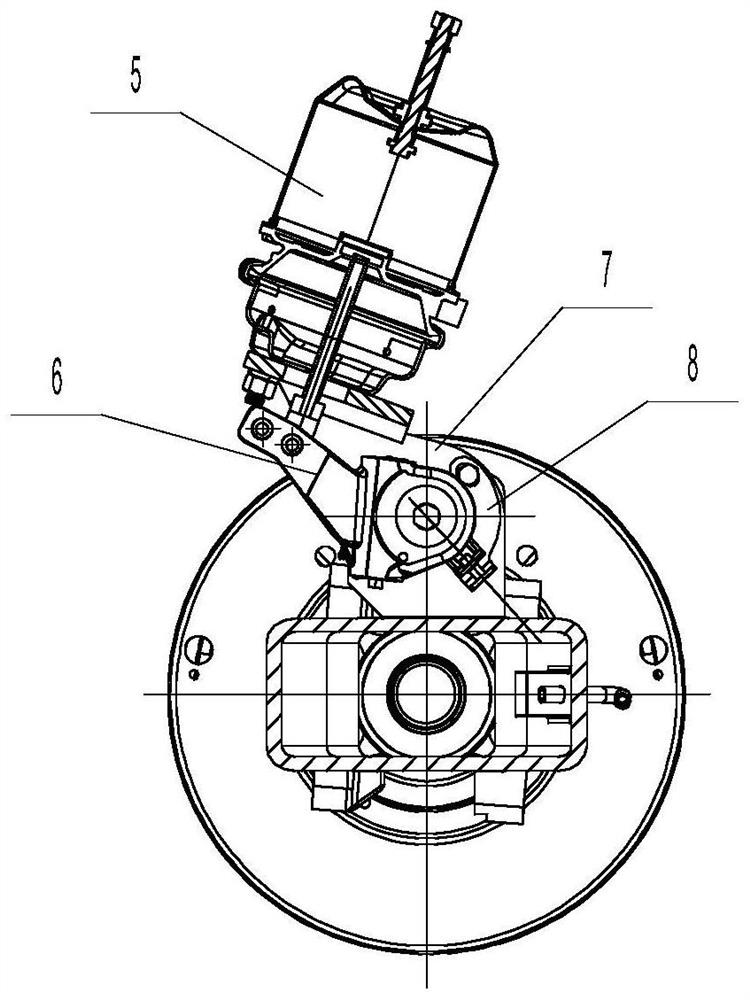

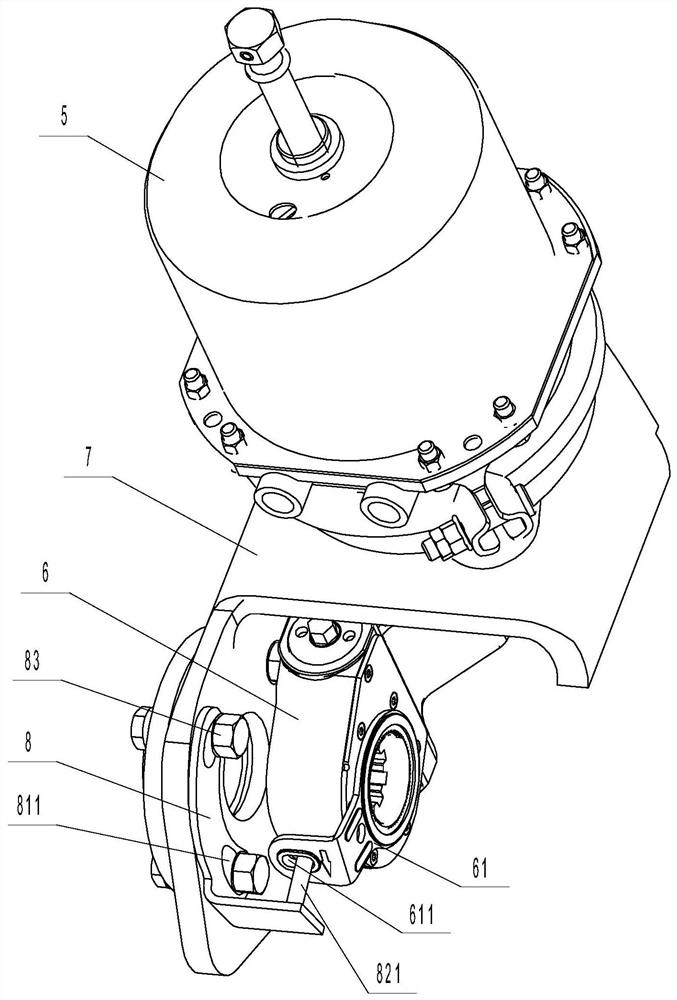

[0040] An automobile rear axle assembly with convenient disassembly and assembly adjustment of the adjustment arm, including rear axle housing assembly 1, main reducer assembly 2, brake assembly 3, wheel hub assembly 4, brake air chamber 5, adjustment arm 6, half-moon Type adjustment bracket 8, wherein:

[0041] The main reduction assembly 2 is installed in the middle of the rear axle housing assembly 1, the brake assembly 3 and the wheel hub assembly 4 are respectively installed at both ends of the rear axle housing assembly 1, and the brake air chamber 5 passes through the air chamber The bracket 7 is fixed on the rear axle housing assembly 1.

[0042] The half-moon-shaped adjustment bracket 8 is a "7"-shaped structure composed of a vertical side plate 81 and a lateral side plate 82. The vertical side plate 81 is an arc half-moon structure, and the upper and lower sides of the vertical side plate 81 The end is also provided with an arc-shaped adjustment slot 811 along the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com