Anti-condensation steel structure roof

A steel structure, anti-condensation technology, applied to roofs, roofs using flat/curved panels, roof coverings, etc., can solve the problems of low thermal insulation effect of thermal insulation cotton, increased processes, materials, and excessive cost increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

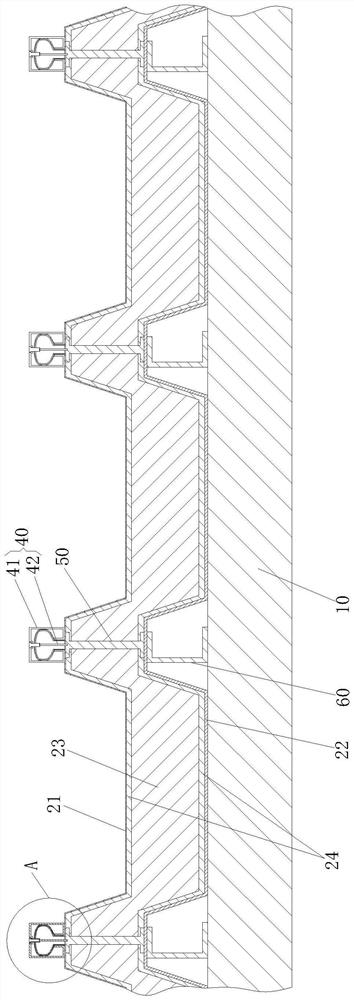

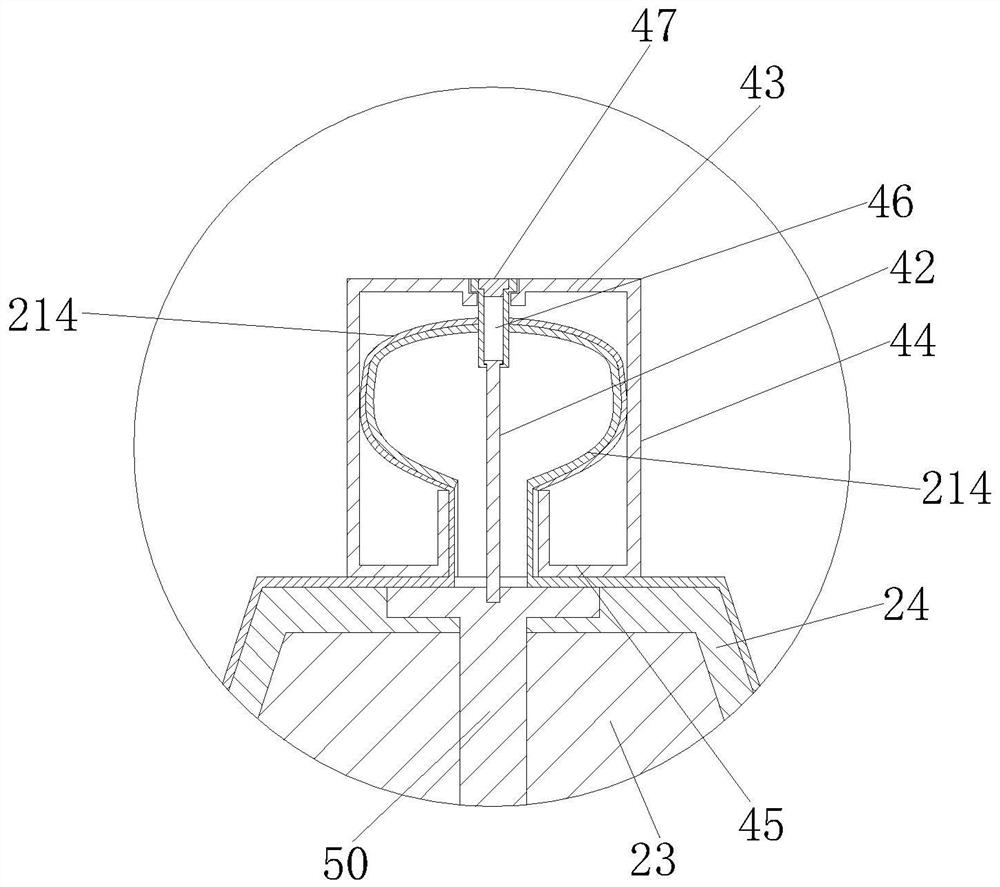

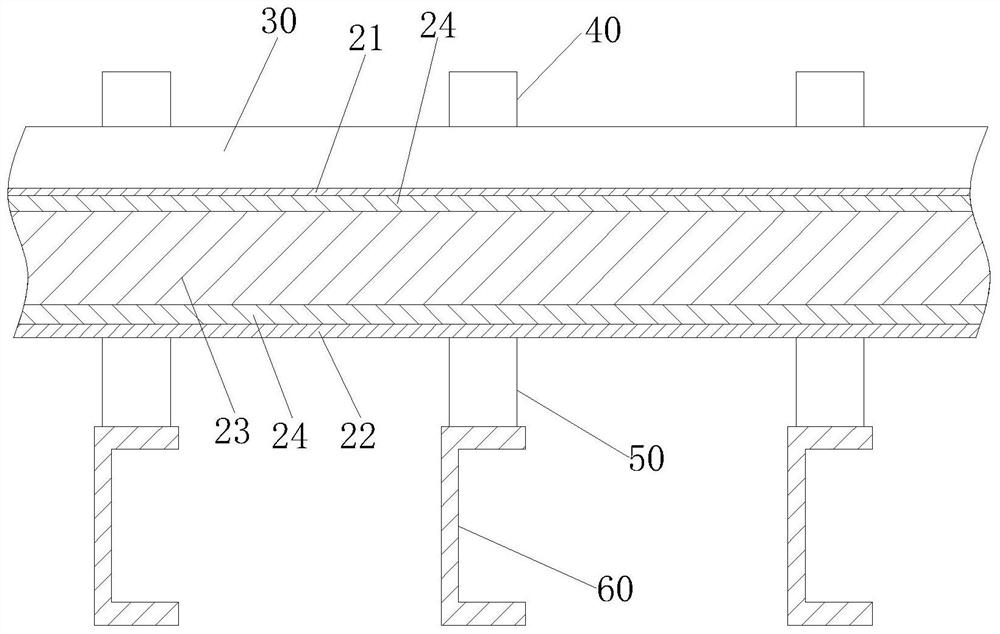

[0028] like figure 1 , image 3 As shown, the anti-condensation steel structure roof described in this embodiment includes several purlins 10 arranged in parallel and a roof arranged on the purlins 10, and the roof is provided with a raised portion 30 perpendicular to the purlins 10;

[0029] The roof includes: an upper layer 21, a lower layer 22, and an insulation layer 23; the upper layer 21 is formed by splicing several upper plates 211, and the upper plates 211 adjacent to each other in the direction parallel to the purlin 10 Overlap at the raised portion 30, the lower plate layer 22 is spliced by several lower plates 221, and overlaps at the raised portion 30 between the adjacent lower plates 221 parallel to the direction of the purlin 10; The raised portion 30 is fixed to the purlin 10;

[0030] Described fixing mechanism comprises: the first fixing mechanism 40 that fixes the upper plate 211 that is adjacent to the direction parallel to the purlin 10, the second fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com