Gas sampling device

A gas sampling and gas outlet technology, applied in the direction of sampling device, etc., can solve the problems of not representing average characteristics, not having automatic acquisition function, complex acquisition device, etc., and achieving the effect of saving installation and disassembly time, convenient disassembly, and flexible installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

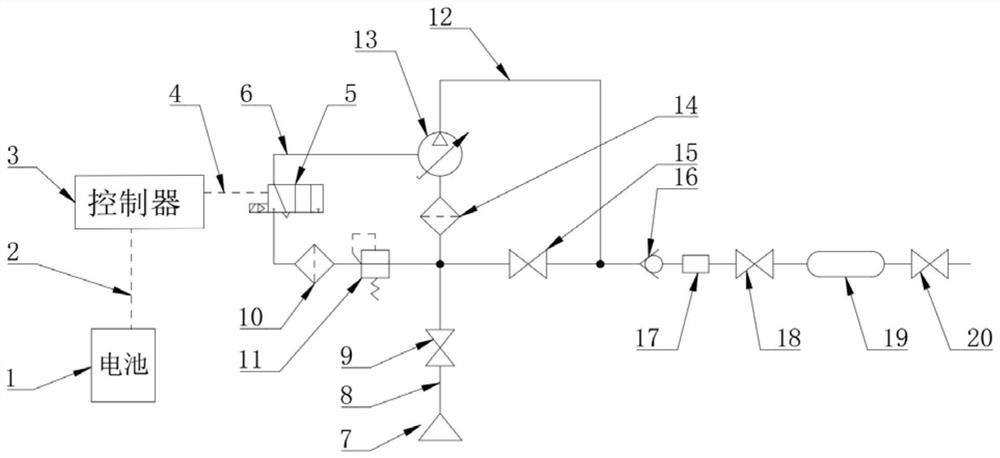

[0023] Such as figure 1 As shown, a gas sampling device includes an air inlet 7 and a solenoid valve 5, wherein the air inlet 7 is connected to an air inlet stop valve 9 through a pipeline 8, and the gas outlet end of the air inlet stop valve 9 is connected to a pressure reducing valve 11 , the outlet end of the pressure reducing valve 11 is connected with a solenoid valve filter 10 , and the outlet end of the solenoid valve filter 10 is connected to the inlet end of the solenoid valve 5 . The above-mentioned components are connected in a sealed manner, and the decompression valve 9 can decompress the high-pressure gas entering from the air inlet 7 to the allowable working pressure of the solenoid valve 5 .

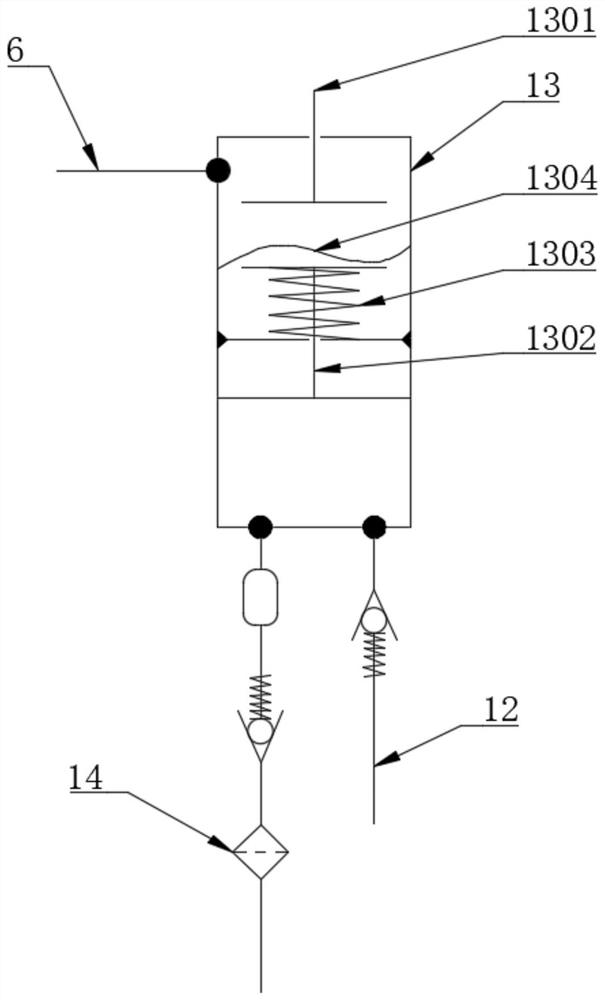

[0024] The air outlet of the solenoid valve 5 is connected to the quantitative pump 13 through the quantitative pump inlet pipe 6. When the solenoid valve 5 is opened, the gas enters the quantitative pump 13 through the quantitative pump inlet pipe 6. When the solenoid va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com