Alignment device suitable for fiber splicing with different fiber diameters

A technology of optical fiber fusion splicing and alignment device, which is applied in the direction of optical waveguide coupling, optics, light guide, etc. It can solve the problems that optical fibers cannot be directly fused, cannot adapt to various optical fiber fusing operations, and the fusing effect is poor, so as to achieve easy operation , Guaranteed welding effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

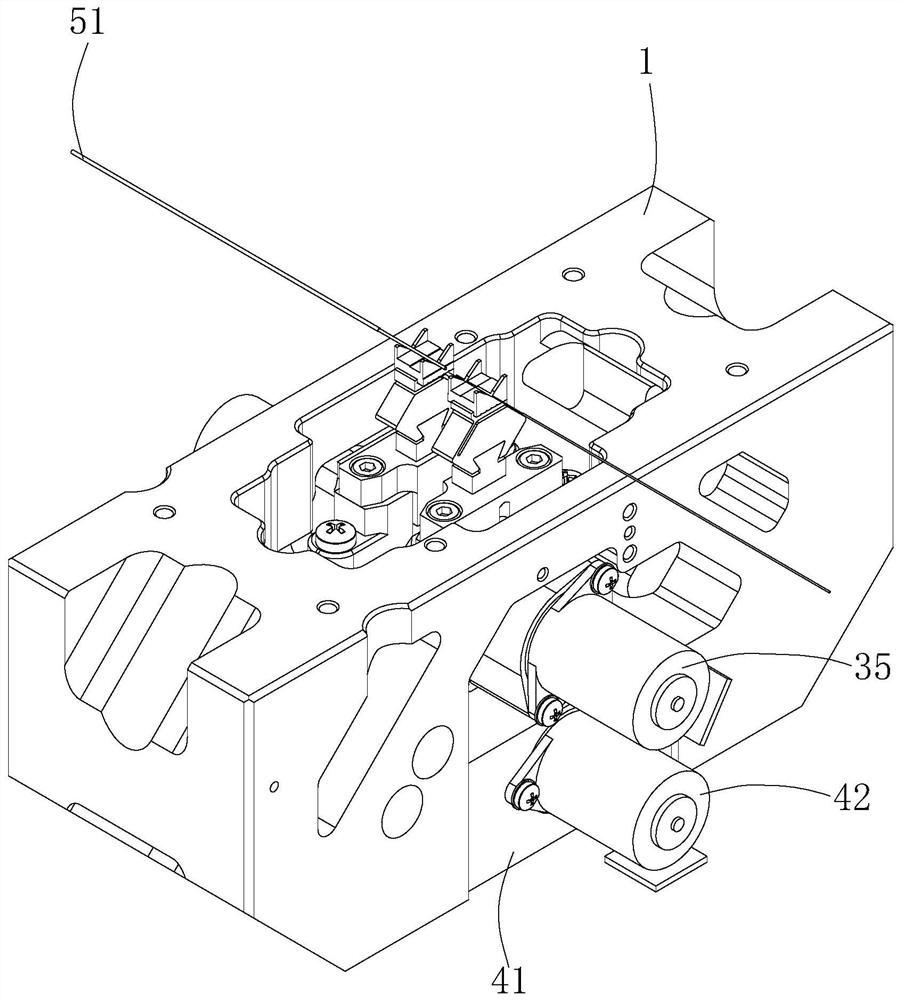

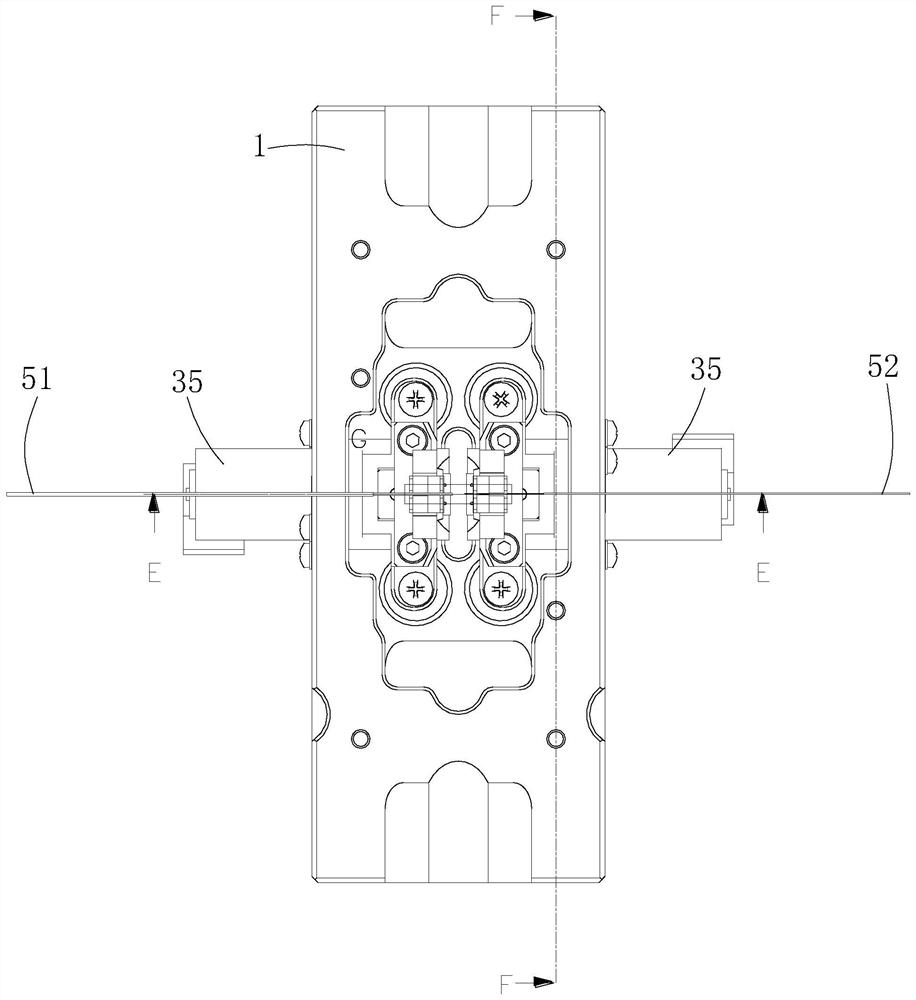

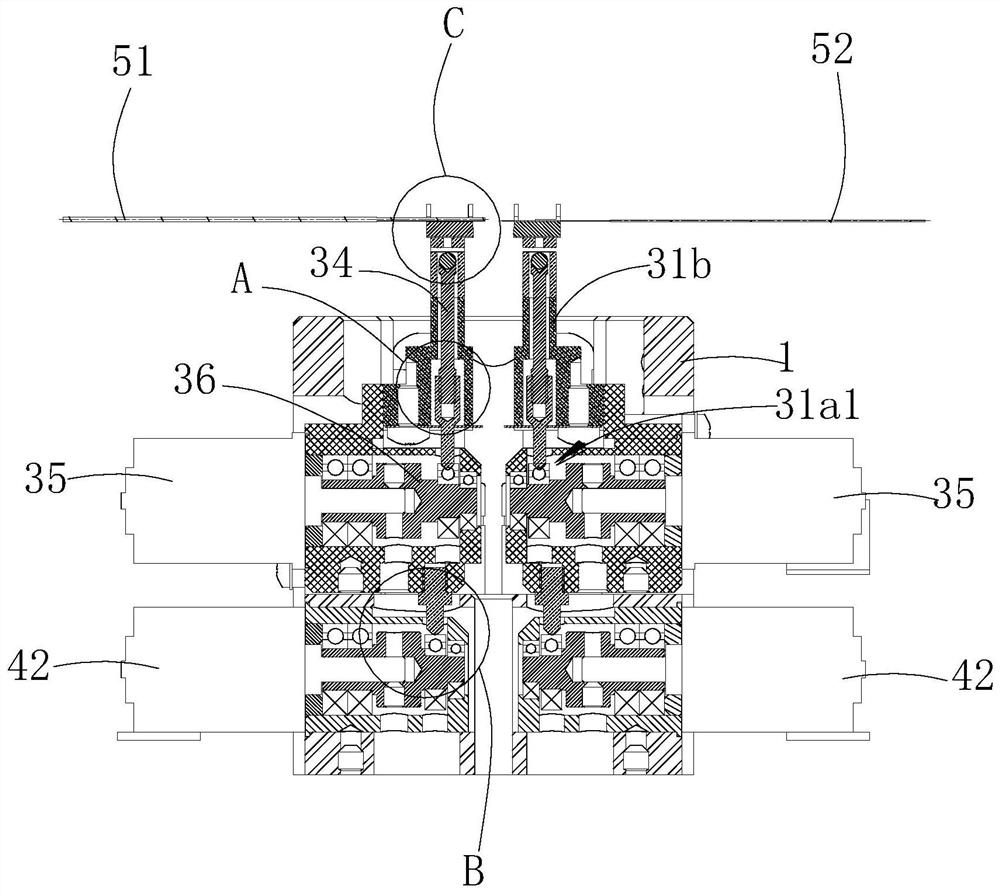

[0029] like Figures 1 to 7 shown

[0030] The alignment device includes a ship-shaped mounting frame 1 and two sets of alignment mechanisms, the two sets of alignment mechanisms are independently arranged in the ship-shaped mounting frame 1, and the two sets of alignment mechanisms are arranged symmetrically on the left and right.

[0031] Each group of alignment mechanisms includes a vertical lifting assembly, a plane fine-tuning assembly and an optical fiber positioning block 2 .

[0032] The plane fine adjustment assembly includes an adjustment seat, an elastic member 32 , a transmission rod 34 , a steel ball 37 , a fine adjustment motor 35 and a first camshaft 36 .

[0033] The transmission rod 34 includes a first rod body 34a at the upper end and a second rod body 34b at the lower end. The upper end surface of the second rod body 34b is provided with a positioning groove 34b1, and the lower end of the first rod body 34a extends into the positioning groove 34b1 of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com