Sheet arranging tool and process for improving concentricity of circulator/isolator ferrite substrate and central conductor

A center conductor and ferrite technology, which is applied in the field of microwave component assembly, can solve the problem of inability to ensure the concentricity of the ferrite substrate and the center conductor, and achieves improved concentricity consistency, convenient operation, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

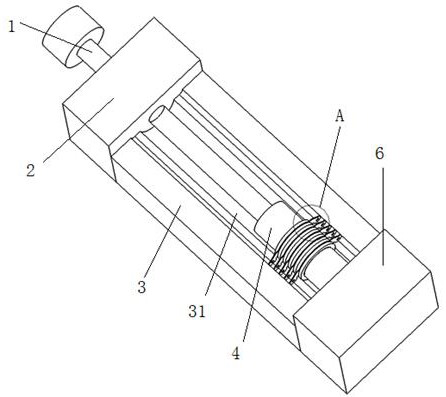

[0027] see figure 1 , a sheet arrangement tool for improving the concentricity between a circulator / isolator ferrite substrate and a central conductor, comprising a screw 1, a lower stop 2, a positioning block 3, a lower punch 4 and an upper stop 6, wherein the The lower block 2 and the upper block 6 are fixedly connected to the two ends of the positioning block 3 with screws respectively, the positioning block 3 is provided with a positioning groove 31, the lower punch 4, the screw rod 1 and the The threaded through-hole connection of the lower stopper 2;

[0028] The process of arranging chips by using the above-mentioned tooling includes the following steps:

[0029] S1. Unscrew the screw 1 of the chip arrangement tool clockwise until the lower punch 4 contacts the lower stopper 2;

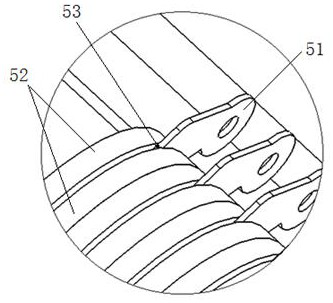

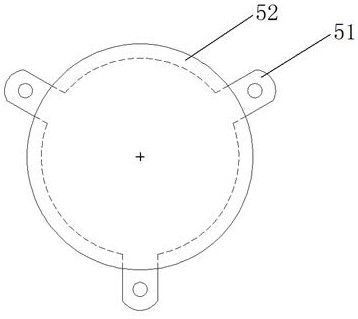

[0030] S2. According to the arrangement order of "a ferrite substrate 52 + a central conductor 51 + a ferrite substrate 52" as a unit group, put several unit groups to be assembled into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com