Portable machine and method for washing and drying cartridge cases for gun or rifle

A portable, cartridge case technology for use in portable machines and fields used to wash and dry cartridge cases for guns or rifles, solving the problems of releasing health, harmful, long cleaning times, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

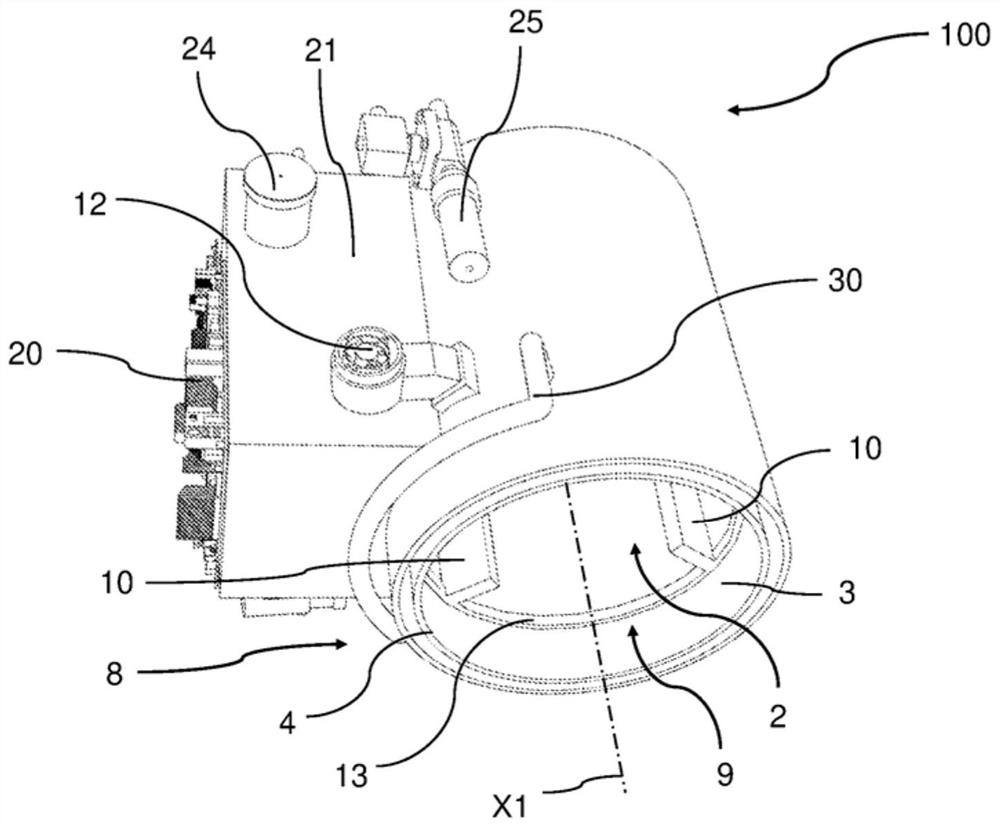

[0018] In the drawings, the same or similar elements are represented by the same numbers.

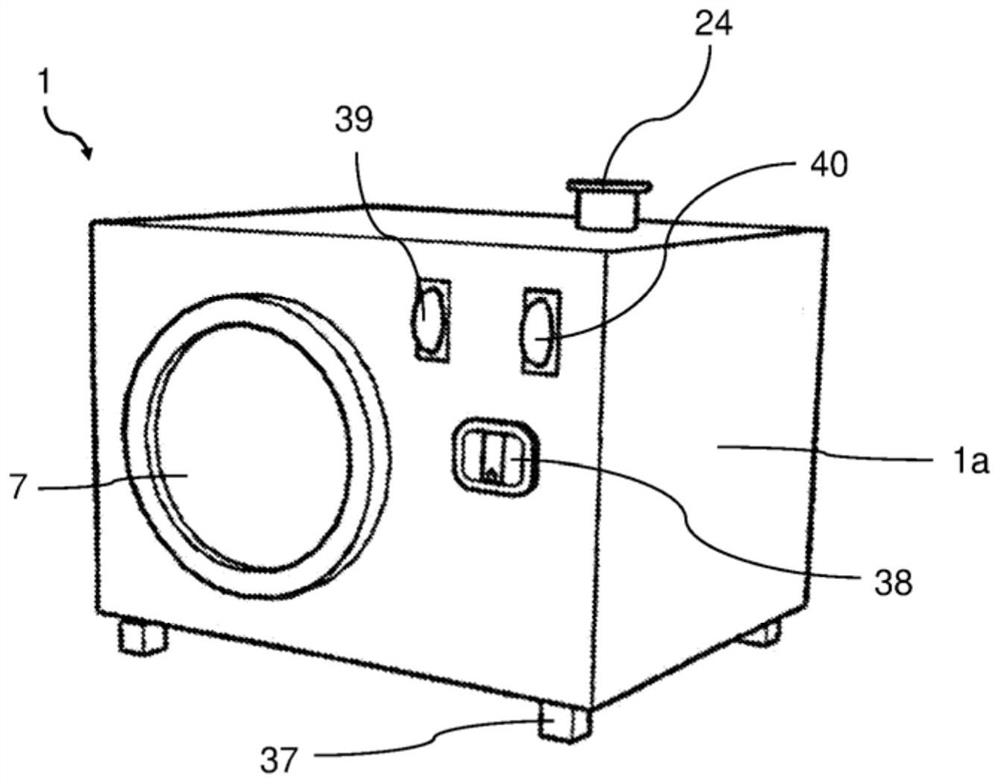

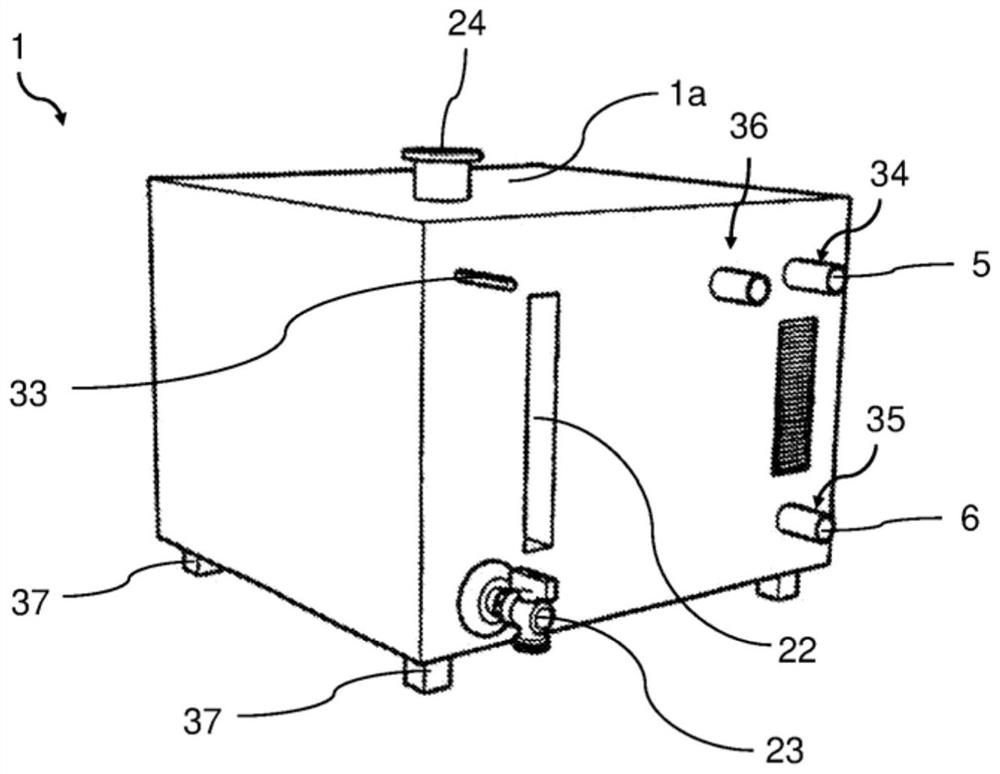

[0019] figure 1 A portable machine for washing and drying cartridge cases of various calibers for guns or rifles according to the currently preferred embodiment is shown, and the portable machine is generally represented by the number 1. According to one embodiment, the machine 1 is a hobby type machine. According to one embodiment, the machine 1 is a machine for washing and drying brass cartridge cases. According to one embodiment, the machine 1 is a machine with cleaning agent recovery, which will be better understood in the following description. For the purpose of this description, it is worth pointing out that the term "portable" with respect to the machine used to wash and dry cartridge cases means that it is easy to transport the machine from one location to another by hand, ie without the use of other tools. position. For the purpose of this specification, portable machines also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com