Pulverizing device for health care product production

A technology for health care products and powder grinding, which is applied in solid separation, sieves, grids, etc., can solve the problems of not meeting the needs of clinical patients for medication, affecting the use effect of medicinal materials, and insufficient uniformity of drug particles, so as to improve the grinding effect and size. The effect of uniform and accelerated grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

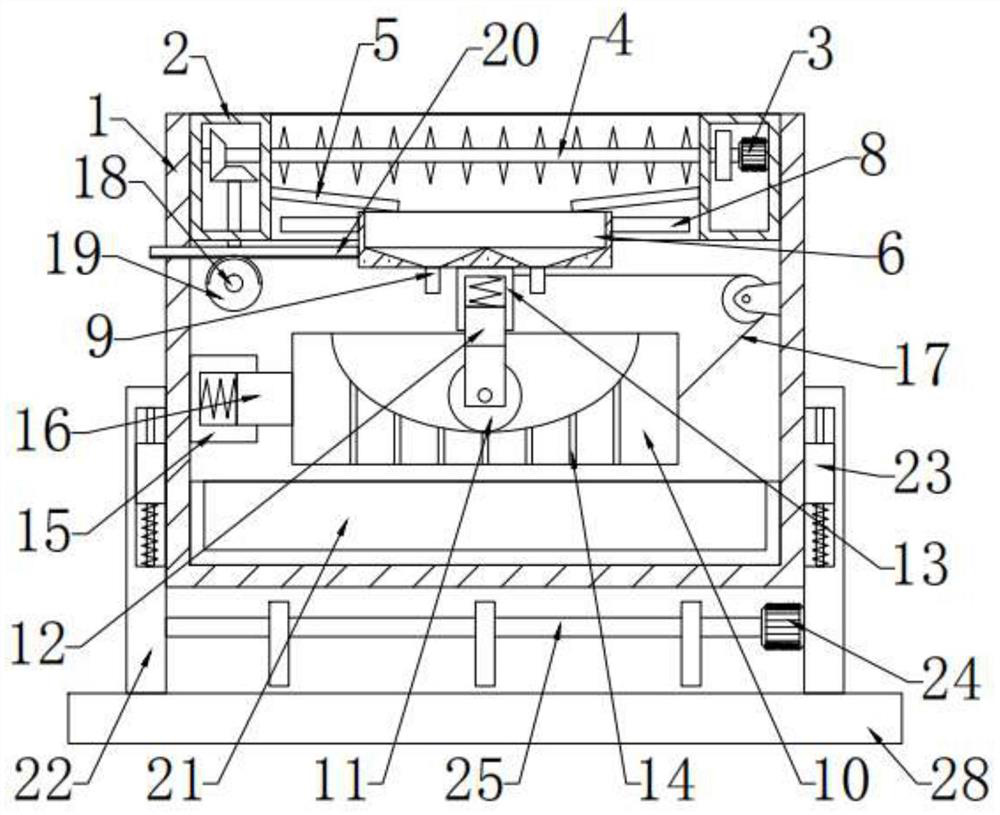

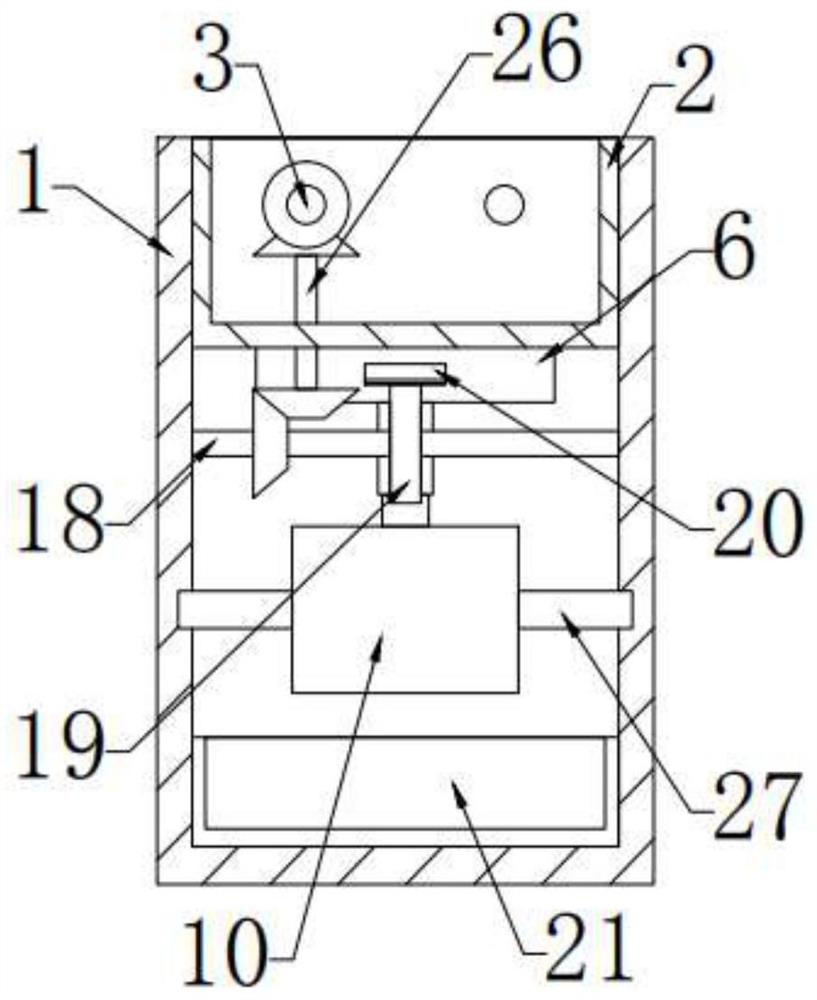

[0025] see Figure 1-3 , in an embodiment of the present invention, a milling device for production of health care products, comprising a grinding box 1, a crushing mechanism is provided on the inner top of the grinding box 1, and a grinding mechanism is provided on the lower side of the crushing mechanism, and the grinding mechanism and The crushing mechanisms are connected by a transmission mechanism, and a vibrating mechanism is provided on the lower side of the grinding box 1 .

Embodiment 2

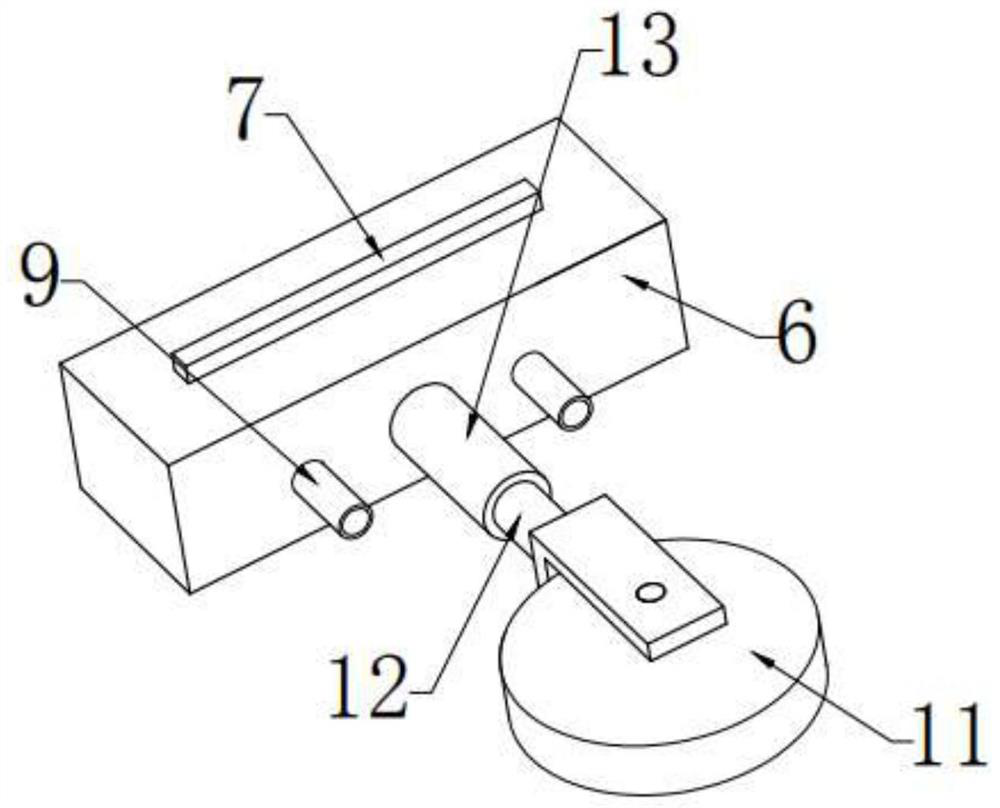

[0027] In this embodiment, the crushing mechanism includes a crushing box 2 fixedly connected to the inner side of the grinding box 1, and a first motor 3 is installed on the inner side of the right end of the crushing box 2 by bolts, and the output end of the first motor 3 is connected to a bearing. The rotating rod 4 that is arranged on the inside of the crushing box 2 is connected, and the rear side of the rotating rod 4 is provided with a second rotating rod that is bearing-connected to the crushing case 2, and the outside of the rotating rod 4 and the second rotating rod are fixedly connected and provided with several The pulverizing blade is provided with a pulverizing mechanism, and the relatively rotating rotating rod 4 and the second rotating rod can fully pulverize the raw material, thereby accelerating the grinding speed.

[0028] In this embodiment, the grinding mechanism includes a grinding seat 10 arranged on the lower side of the crushing box 2, an arc-shaped gri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap