Novel fishery administration wharf boat

A fishery and pontoon technology, applied in buoys and other directions, can solve the problems of deformation and damage of the retaining plate, breaking of the retaining plate, extrusion of the retaining plate, etc., to reduce labor intensity, high safety, and good shielding effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

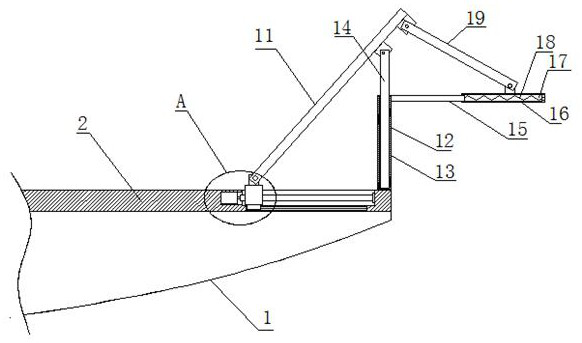

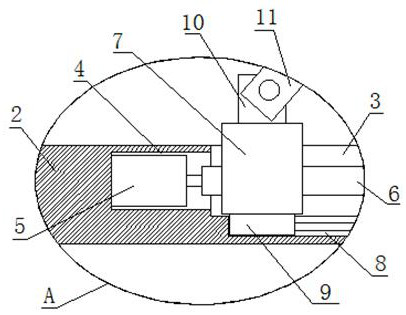

[0020] refer to Figure 1-2 , a new type of fishery pontoon, comprising a hull 1, a deck 2 is provided on the hull 1, a transmission slot 3 is provided on the top of the deck 2, a motor slot 4 is provided on the inner wall of one side of the transmission slot 3, and a motor slot 4 is provided on one side of the motor slot 4 A rotating motor 5 is fixedly installed on the inner wall, and a screw rod 6 is fixedly installed on the output shaft of the rotating motor 5. The screw rod 6 is threadedly connected with a threaded seat 7, and the bottom of the threaded seat 7 is fixedly installed with a square horizontal block 9 and a transmission groove 3 A square chute 8 is provided on the bottom inner wall of the square chute 8, and the bottom of the square horizontal block 9 extends into the square chute 8, and the same horizontal bar is fixedly installed on the inner walls of both sides of the square chute 8, and the square horizontal block 9 is slidably installed on the On the horiz...

Embodiment 2

[0027] refer to Figure 1-2 , a new type of fishery pontoon, comprising a hull 1, a deck 2 is provided on the hull 1, a transmission slot 3 is provided on the top of the deck 2, a motor slot 4 is provided on the inner wall of one side of the transmission slot 3, and a motor slot 4 is provided on one side of the motor slot 4 A rotating motor 5 is fixedly installed on the inner wall, and a screw rod 6 is fixedly installed on the output shaft of the rotating motor 5. The screw rod 6 is threadedly connected with a threaded seat 7, and the bottom of the threaded seat 7 is fixedly installed with a square horizontal block 9 and a transmission groove 3 A square chute 8 is provided on the bottom inner wall of the square chute 8, and the bottom of the square horizontal block 9 extends into the square chute 8, and the same horizontal bar is fixedly installed on the inner walls of both sides of the square chute 8, and the square horizontal block 9 is slidably installed on the On the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com