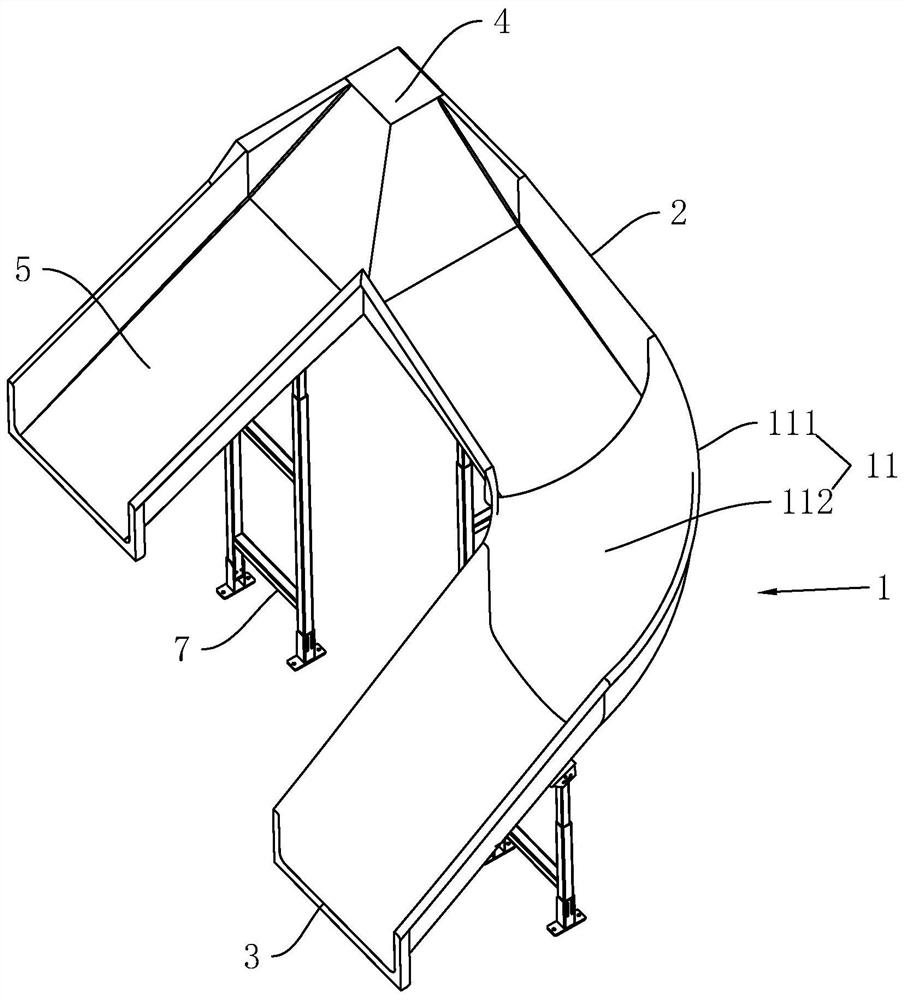

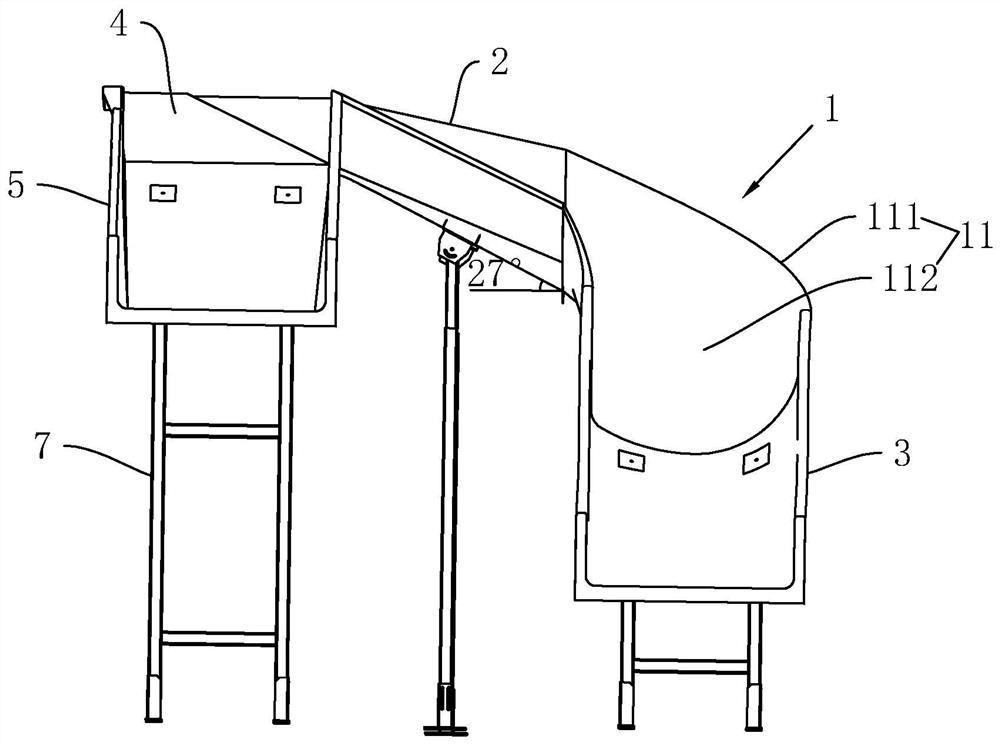

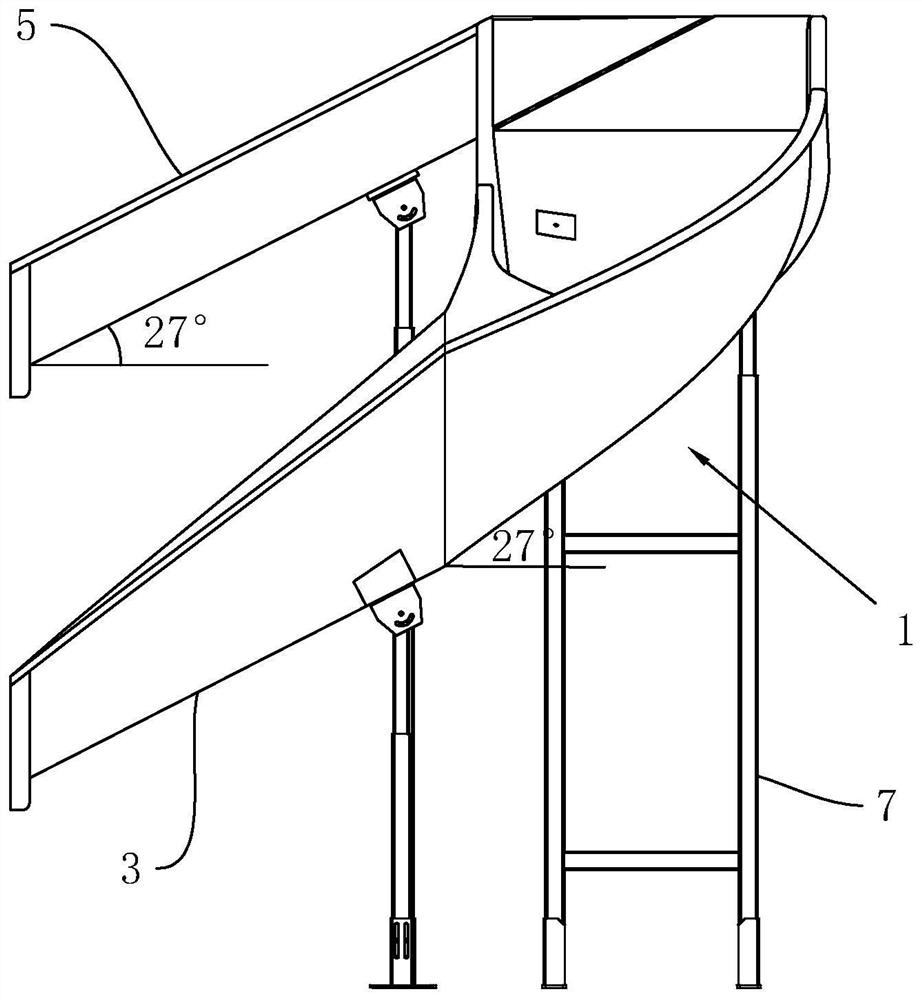

Logistics sorting chute and manufacturing method thereof

A production method and technology of chute, which is applied in the direction of chute, transportation and packaging, etc., can solve the problems of damaged goods, waste of space, large space, etc., and achieve the effect of less space and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0058] Embodiment 3, a manufacturing method of a logistics sorting chute, comprising the following steps:

[0059] S1. Use a 3D engraving machine to carve the bending section 1, the entrance straight section 2 and the exit straight section 3 with foam, and call this model a model;

[0060] S11. Splicing each mold type together by gluing to form the actual shape of a section of chute;

[0061] S2. Manufacture a mold for making the bending section 1 based on the model, specifically: first brush a layer of gel coat on the surface of the groove of the model, and then spread a layer after the gel coat is cured Glass fiber, and then spread a layer of unsaturated resin on the glass fiber, mix it with the glass fiber, fix the glass fiber on the gel coat at the same time, and then alternately lay glass fiber and unsaturated resin on the unsaturated resin Saturate the resin until the required thickness is reached and stop laying;

[0062] S21. After the unsaturated resin is completely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com