Precast beam hoisting construction method in warehouse logistics building

A technology of warehousing logistics and construction methods, which is applied in the directions of transportation and packaging, load hoisting components, cranes, etc., can solve the problems of many concrete prefabricated parts, low hoisting efficiency, and large safety hazards, so as to improve hoisting and installation efficiency, reduce Construction safety hazards and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

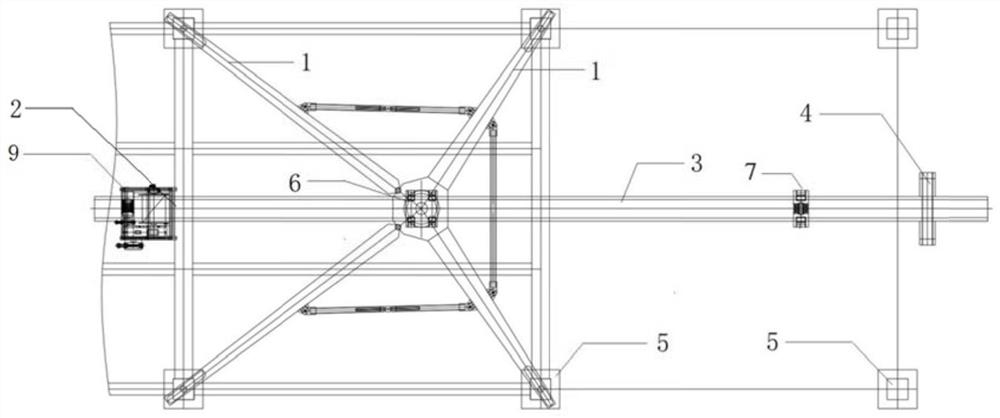

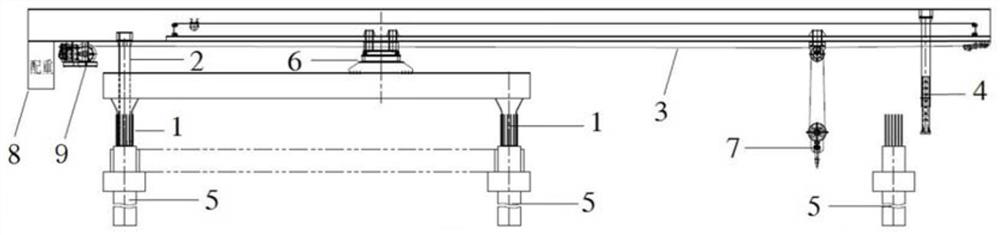

[0059] Such as figure 1 and 2 As shown, it is the structural form of the climbing hoisting equipment adopted in the present invention, and its main structural components include chassis outrigger 1, rear outrigger 2, main arm 3, front outrigger 4, rotating chassis 6, hook 7, counterweight 8. Among them, the slewing chassis 6 is the main supporting part of the whole climbing hoisting equipment. The slewing chassis 6 is provided with four chassis legs 1 for supporting the frame column 5, of which the two at the front end are fixed legs, and the two at the rear end are fixed legs. The two are movable outriggers, the distance between the supporting ends between the two fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com