Movable cast-in-place beam side formwork device and using method thereof

A cast-in-place beam and mobile technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as high safety risks in hoisting operations, expensive supporting equipment, and self-heavy formwork, so as to achieve a simple and feasible combined structure, Easy to install and disassemble, to ensure the effect of pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

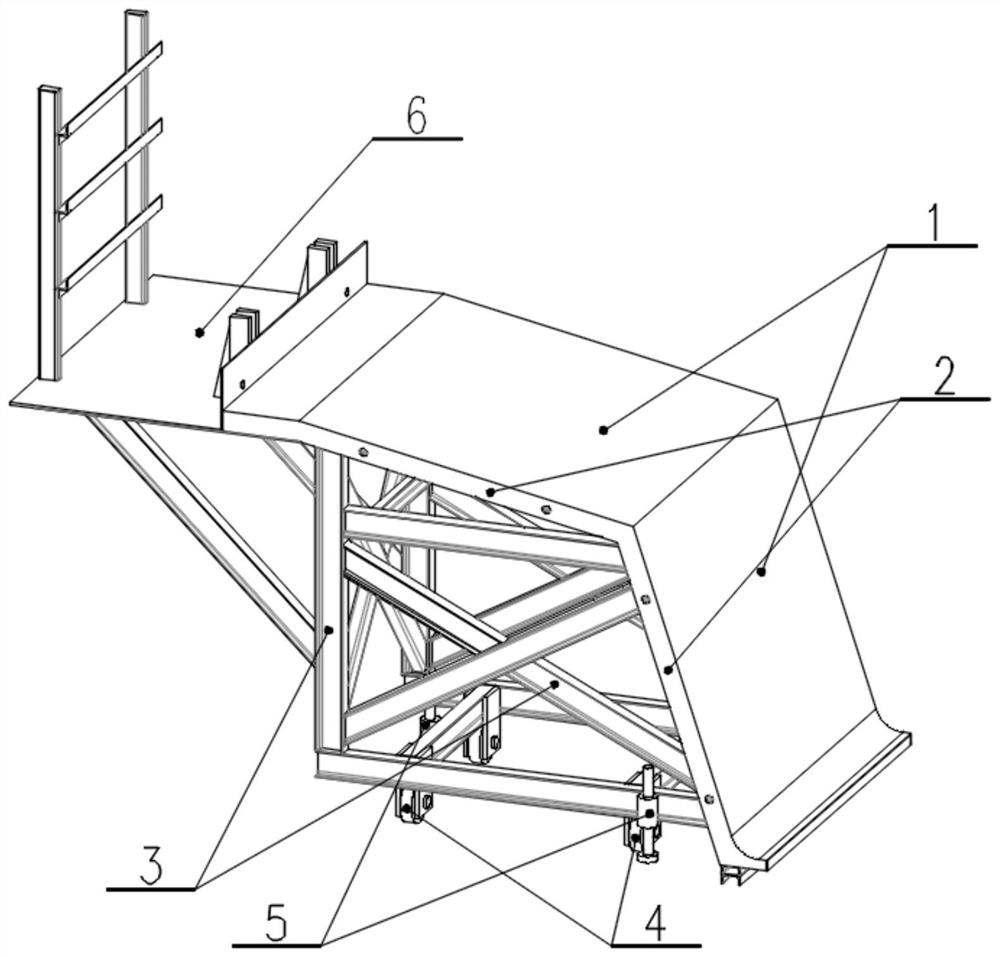

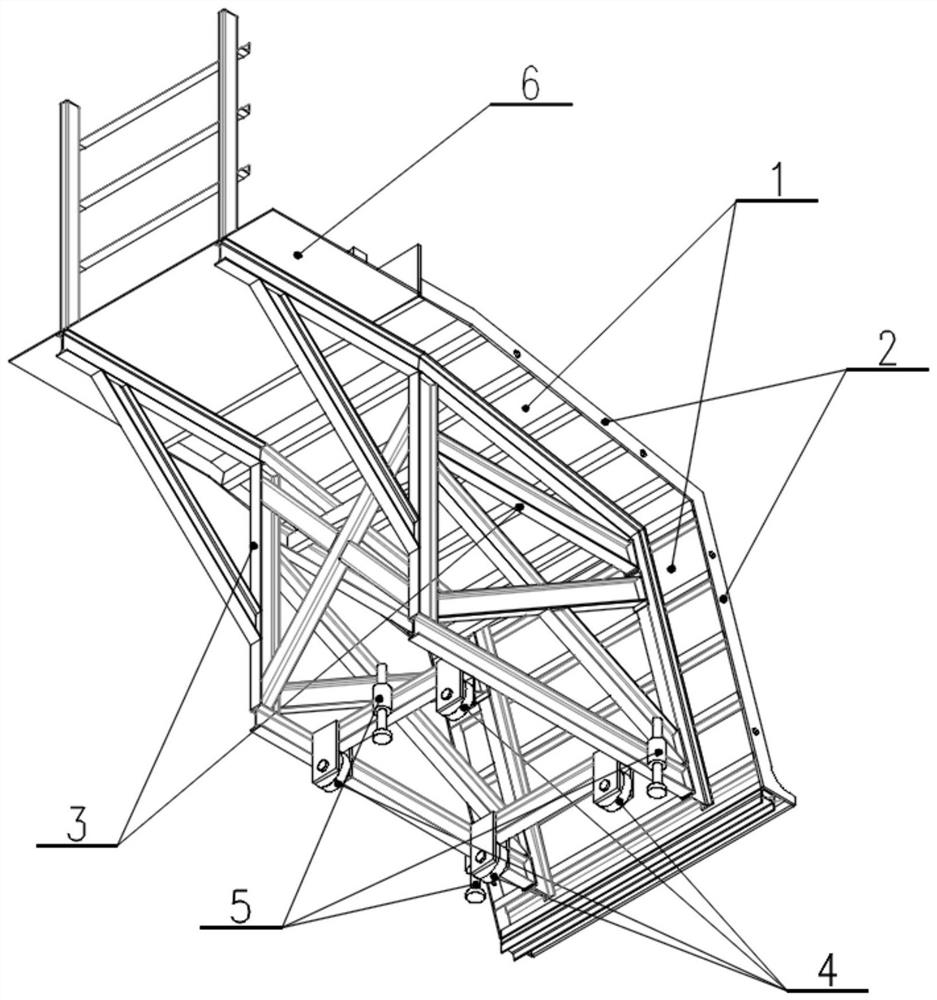

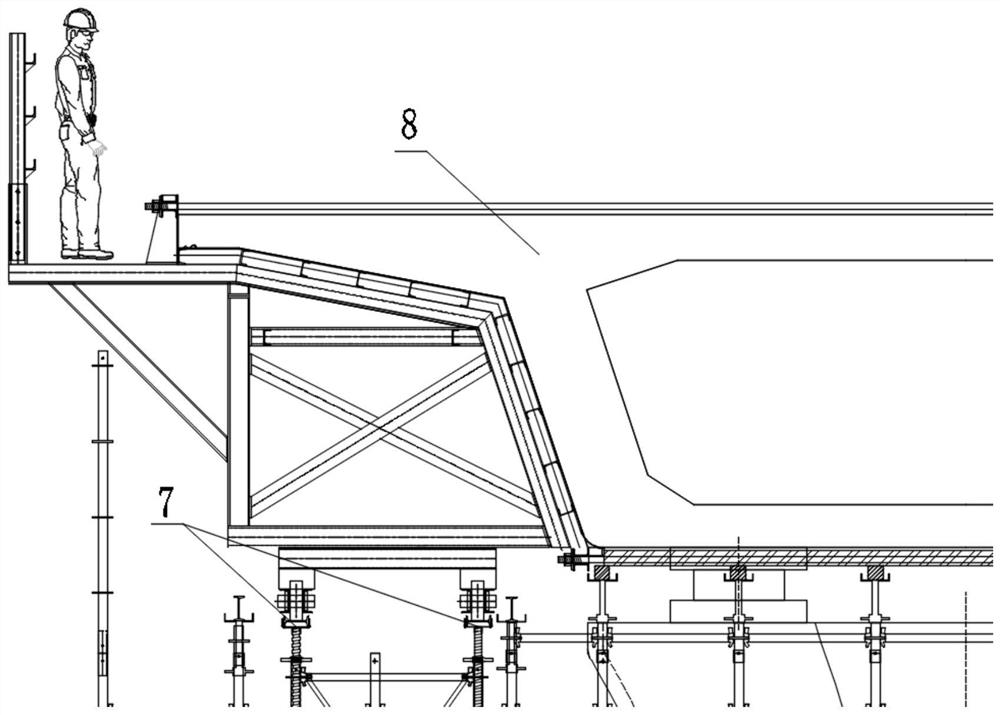

[0033] combine image 3 As shown, when in use, after the support and channel steel track are erected, the mobile cast-in-place beam side form is hoisted from the beam end to the support, and the running wheels are dropped into the channel steel track to pair the formwork units It is arranged on both sides of the cast-in-place beam, and the number of formwork units is determined according to the length of a single pouring.

[0034] Then, the formwork units are manually pushed to the predetermined position one by one, so that two adjacent formworks are close together, and wooden wedges are inserted under the running wheels to fix them. After the formwork unit is in place, pass the bolts through the two outer ribs on the back of the work plate to connect the formwork unit as a whole. If necessary, use jacks and other tools to fine-tune the horizontal position of the formwork.

[0035] Then, adjust the jacking screws of each formwork unit in turn to make the horizontal inclinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com