Assembly type joint for steel structure

A prefabricated, steel structure technology, used in building components, building structures, covering/lining, etc., can solve the problems of inability to apply external wall panels, unstable fixing of columns and wall panels, and achieve structural stability and structural stability. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

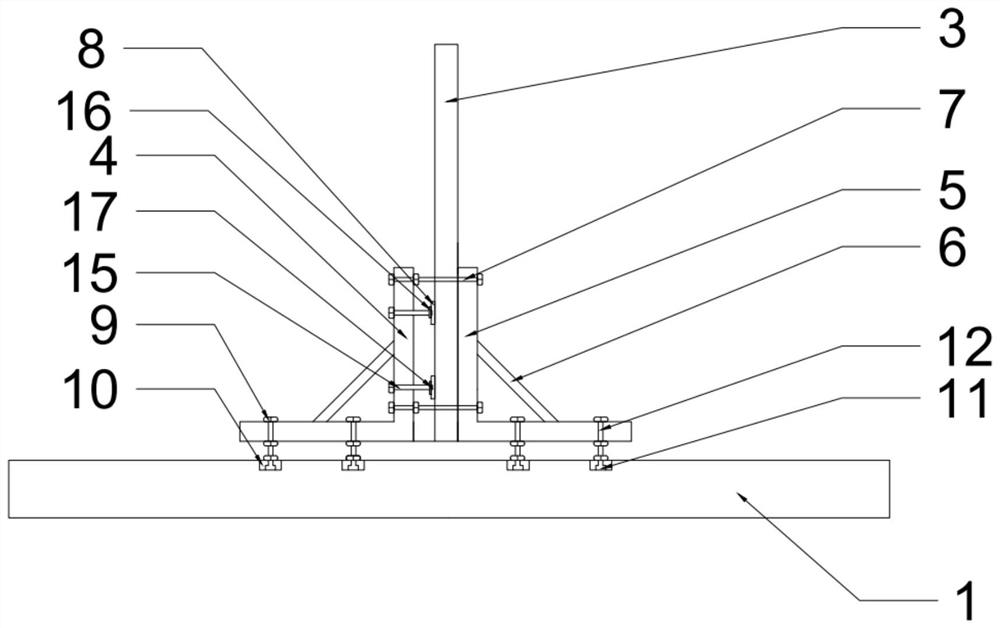

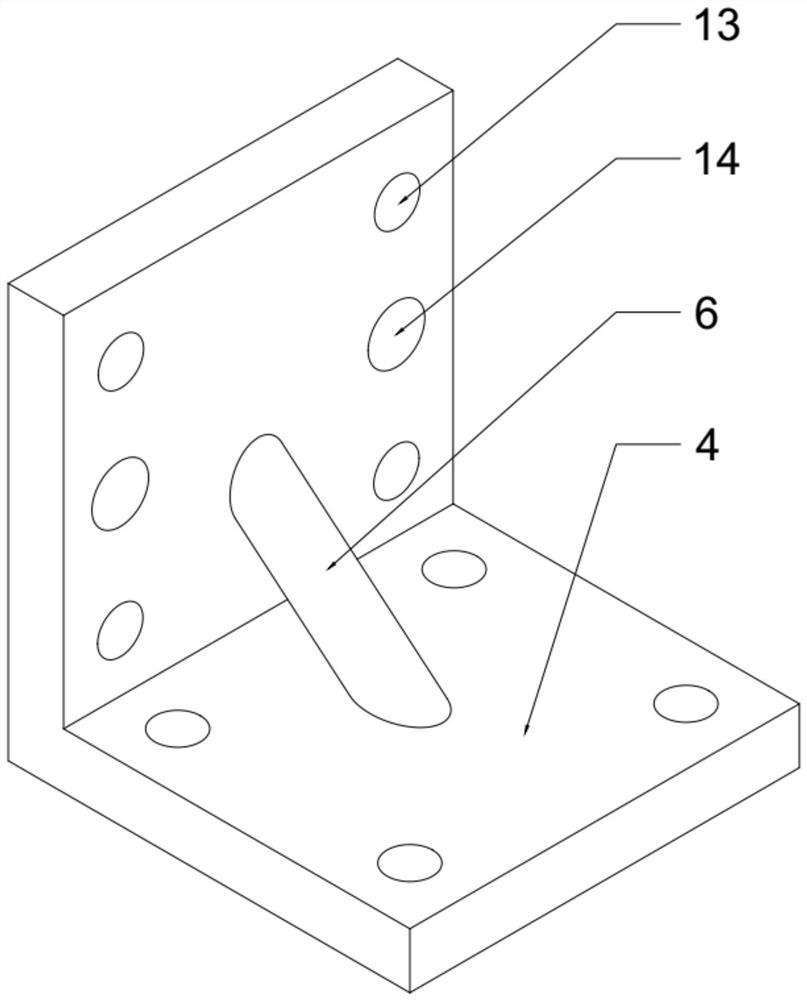

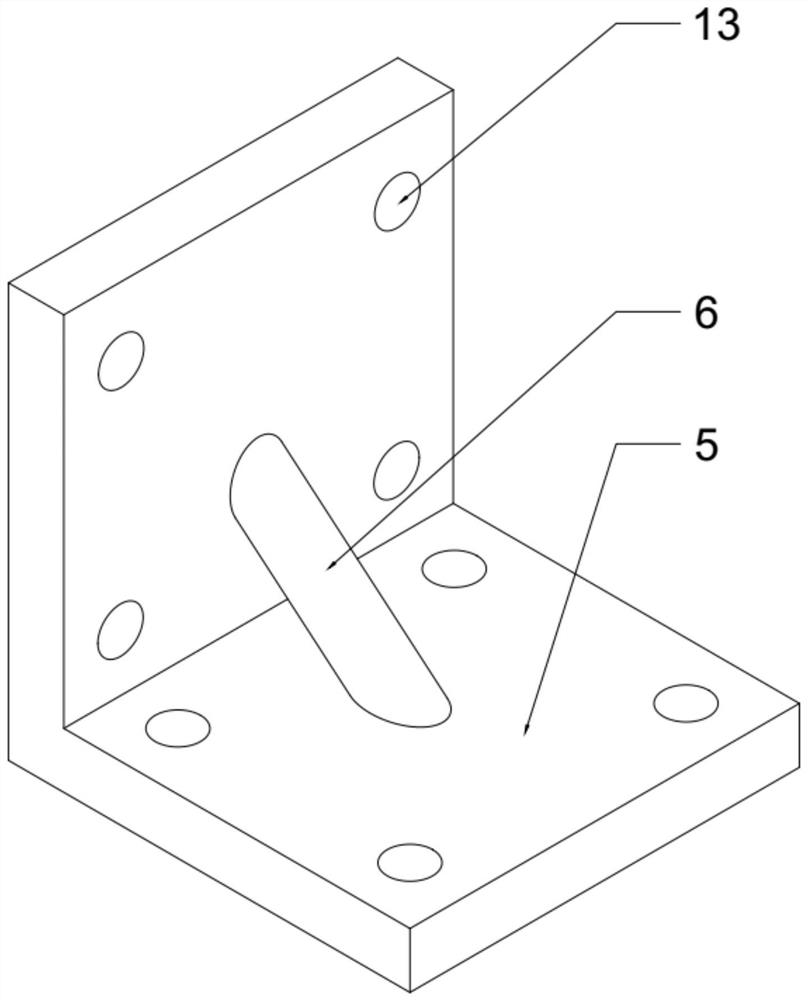

[0018] Below will combine the appended in the embodiment of the present invention Figure 1-3 , clearly and completely describe the technical solutions in the embodiments of the present invention.

[0019] The invention provides a technical solution:

[0020] External wall panel 1, external wall panel 3, left limit steel plate 4, right limit steel plate 5, support column 6, screw rod 7, top plate 8, nut 9, filling cavity 10, positioning block 11, screw rod 12, screw rod Holes 13, screw holes 14, top posts 15, snap rings 16, magnets 17, including the filling cavity 10 are fixedly connected in the exterior wall panel 1, the outside of the filling cavity 10 is bonded to the exterior wall panel 1 through concrete, and the positioning block 11 is nested Connected inside the filling cavity 10, the outer surface of the positioning block 11 is fixedly connected with the filler in the filling cavity 10, the positioning block 11 is fixedly connected with one end of the rotary rod 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com