High-strength electromagnetic shielding cable

An electromagnetic shielding and high-strength technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of communication signal information error and distortion, etc., to increase tensile and compressive performance, best electromagnetic shielding performance, and improve strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

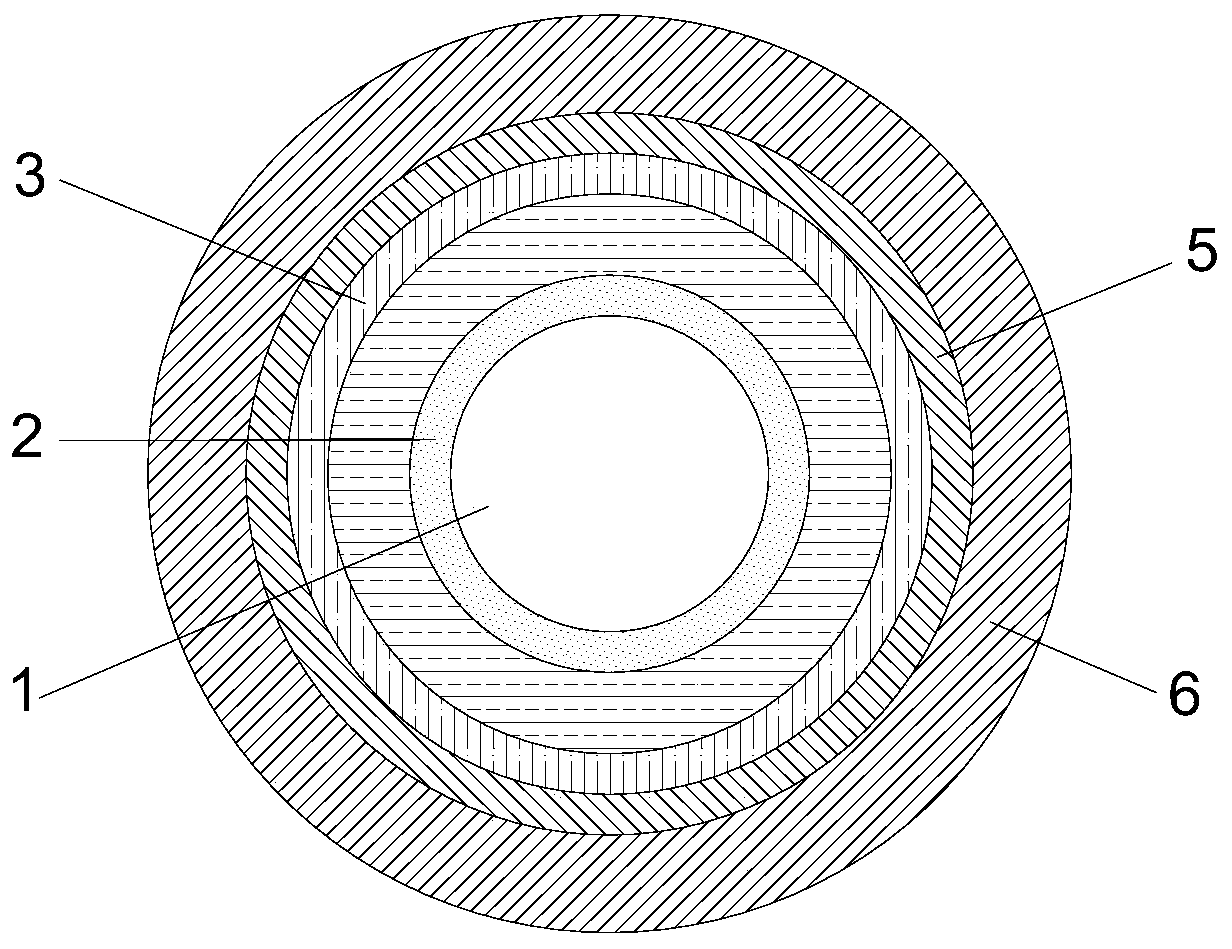

[0034] see figure 1 , this embodiment discloses a high-strength electromagnetic shielding cable, including a cable core and a refractory layer, an isolation layer, a shielding layer, and a flame-retardant sheath layer that are sequentially coated on the outside of the cable core; the cable core includes a The copper conductor is formed by twisting a plurality of copper wires. The fire-resistant layer is a fire-resistant tape, and the fire-resistant tape is ceramic fiber cloth wrapped around the outside of the wire core, with a thickness of 100-200 μm.

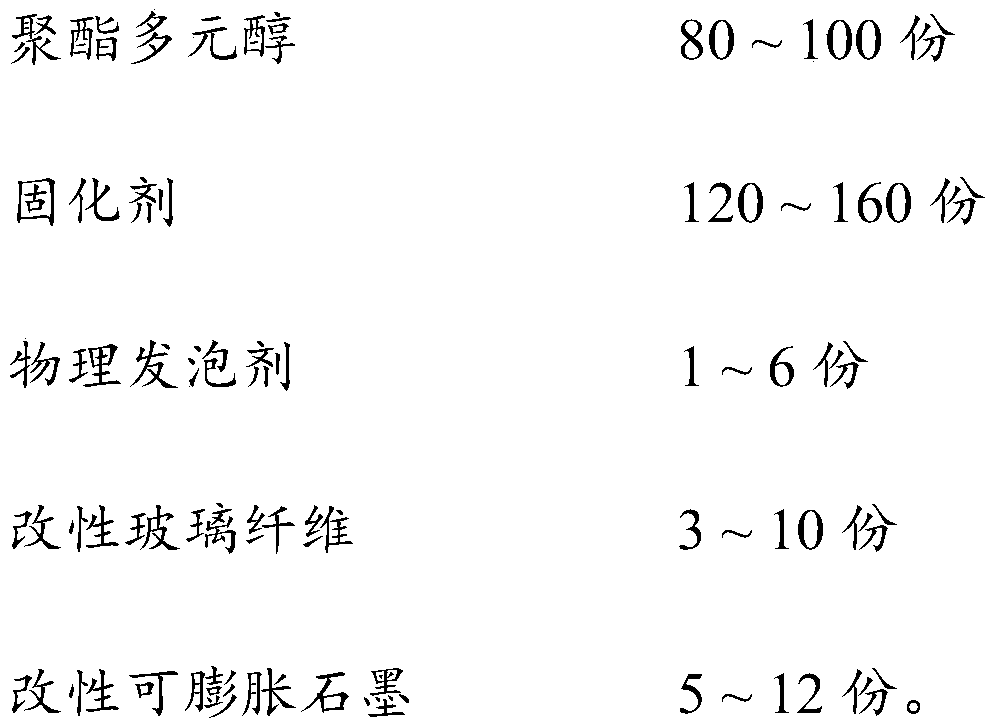

[0035] The isolation layer is a polyurethane / glass fiber / expandable graphite ternary composite foam layer with a thickness of 200-400 μm; the preparation method is as follows:

[0036] (1) Take by weighing two parts of coupling agent KH550 according to 2wt% and 5wt% of glass fiber and expandable graphite, and dissolve them in absolute ethanol respectively to obtain two parts of coupling agent solutions with a concentration of ...

Embodiment 2

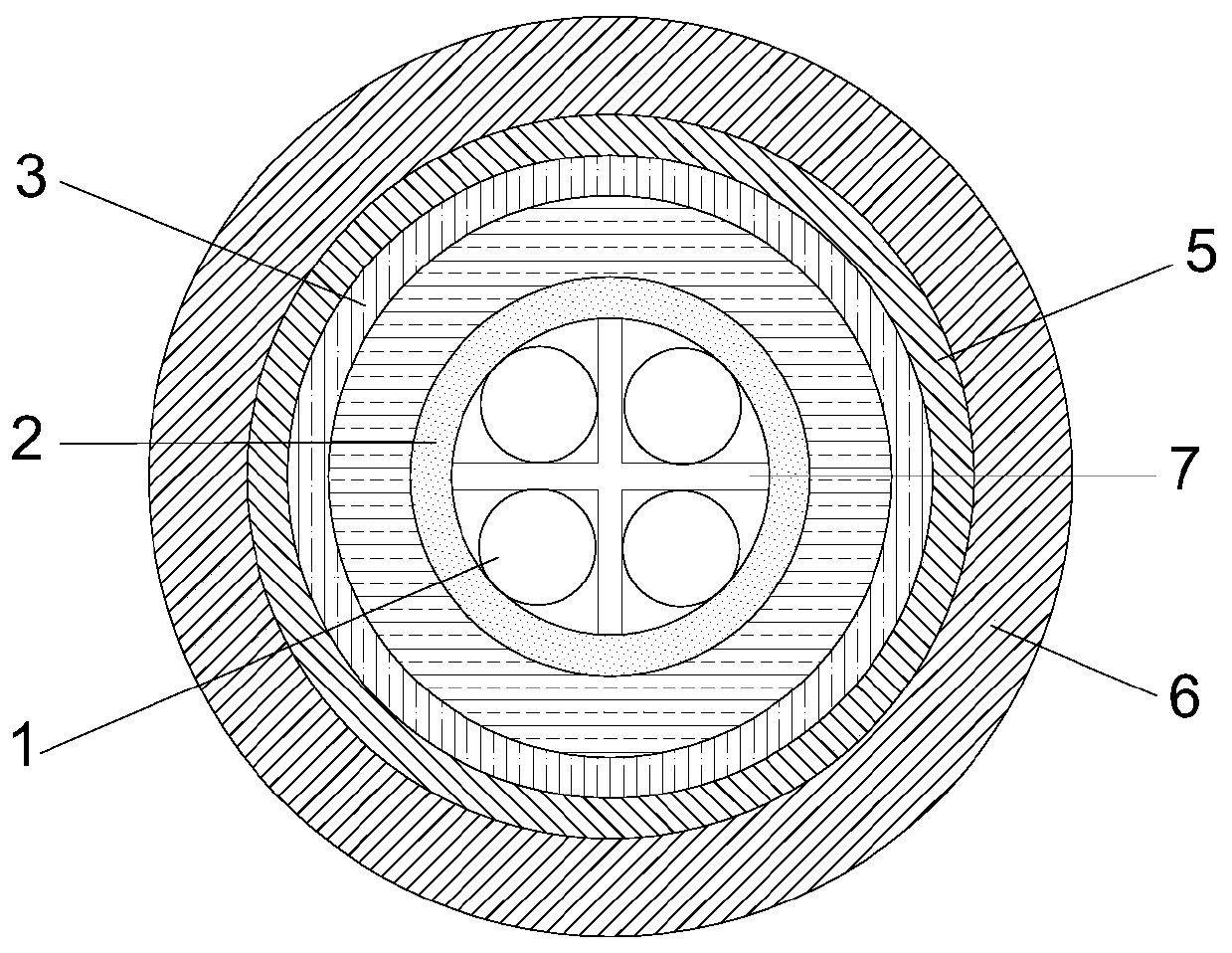

[0042] see figure 2 , this embodiment discloses a high-strength electromagnetic shielding cable, including a cable core and a refractory layer, an isolation layer, a shielding layer, and a flame-retardant sheath layer that are sequentially coated on the outside of the cable core; the cable core includes 4 A copper conductor and a cross-shaped filling frame, wherein the copper conductor is formed by twisting a plurality of copper wires, and is separated and relatively fixed by the cross-shaped filling frame. The fire-resistant layer is a fire-resistant tape, and the fire-resistant tape is a ceramic polyimide tape wrapped around the outside of the cable core, with a thickness of 100-200 μm.

[0043] The isolation layer is a polyurethane / glass fiber / expandable graphite ternary composite foam layer with a thickness of 200-400 μm; the preparation method is as follows:

[0044] (1) Take by weighing two parts of coupling agent KH550 according to 2wt% and 5wt% of glass fiber and exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com