Method for improving mechanical properties of hydrogel fibers by secondary crosslinking

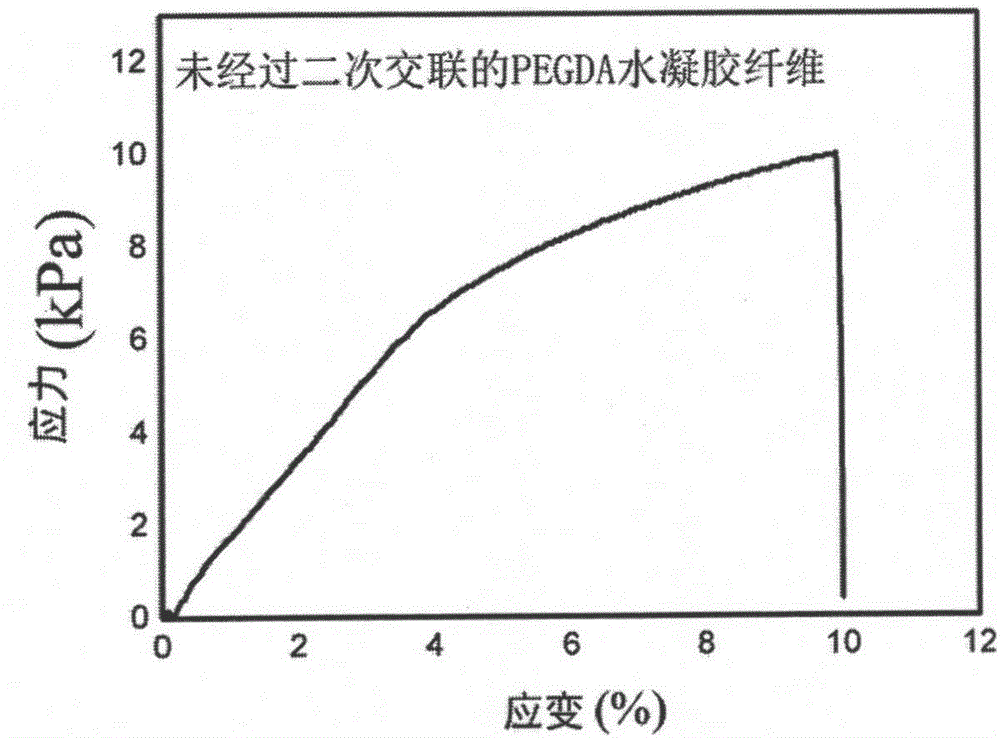

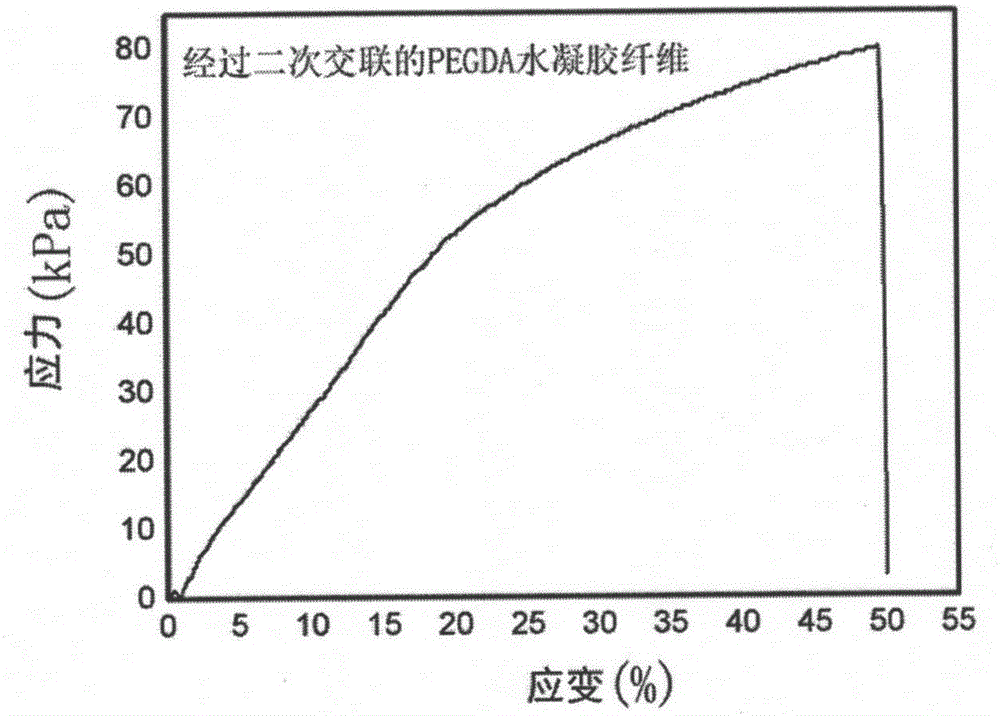

A secondary cross-linking, hydrogel technology, applied in the chemical characteristics of fibers, wet spinning, chemical post-processing of synthetic polymer rayon filaments, etc., can solve the problems of continuous preparation of hydrogel fibers, poor mechanical properties, Low cross-linking degree and other problems, to achieve the effect of low production cost, improved tensile and compressive properties, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for secondary crosslinking to improve the mechanical properties of hydrogel fibers, the specific steps are:

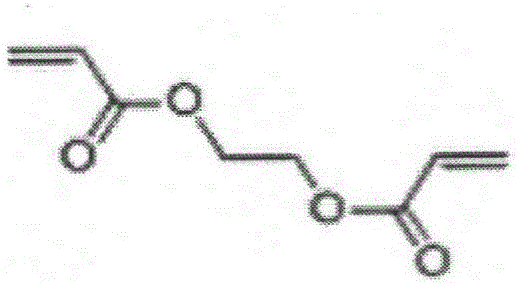

[0026] (1) Weigh 5 g of deionized water, 3 g of polyethylene glycol diacrylate (PEGDA, Mn=300), 0.05 g of IRGACURE 2959 at room temperature, and magnetically stir for 7 hours in the dark at room temperature until IRGACURE 2959 is completely dissolved to obtain a spinning solution;

[0027] (2) Spinning solution is injected in the syringe of 10ml measuring range, uses the capillary tube of inner diameter 0.6mm, long 2cm as spinning nozzle, utilizes metering pump to inject spinning solution from syringe through spinning nozzle into ionic water bath, advancing rate 2.5ml / h, the spinning nozzle is immersed 0.5cm below the surface of the water bath. Set a 90° ultraviolet point light source at a distance of 6 mm from the spinneret, with a wavelength of 400 m, set a drum with a diameter of 6 cm at a linear speed of 350 m / h, and collect the nascent hydrogel fi...

Embodiment 2

[0030] A method for secondary crosslinking to improve the mechanical properties of hydrogel fibers, the specific steps are:

[0031] (1) Weigh 10 g of deionized water, 7 g of PEGDA (Mn=500), and 0.03 g of IRGACURE 2959 at room temperature, and magnetically stir for 7 hours in the dark at room temperature until IRGACURE 2959 is completely dissolved to obtain a spinning solution;

[0032] (2) Spinning solution is injected in the syringe of 10ml measuring range, is spinning nozzle with the capillary tube of internal diameter 0.6mm, long 2cm, utilizes metering pump to inject spinning solution from syringe through spinning nozzle into ion water bath, propulsion speed 4ml / h, the spinning nozzle is immersed 0.5cm below the surface of the water bath. Set a 90° ultraviolet point light source at a distance of 6mm from the spinneret, with a wavelength of 400nm, set a drum with a diameter of 6cm at a linear speed of 400m / h, and collect the nascent hydrogel fibers by winding to obtain con...

Embodiment 3

[0035] A method for secondary crosslinking to improve the mechanical properties of hydrogel fibers, the specific steps are:

[0036] (1) Weigh 10 g of deionized water, 7 g of polypropylene glycol diacrylate (PPGDA, Mn=600), 0.03 g of IRGACURE 2959 at room temperature, and magnetically stir for 7 hours in the dark at room temperature until IRGACURE 2959 is completely dissolved to obtain a spinning solution;

[0037](2) Spinning solution is injected in the syringe of 10ml measuring range, is spinning nozzle with the capillary tube of internal diameter 0.6mm, long 2cm, utilizes metering pump to inject spinning solution from syringe through spinning nozzle into ion water bath, propulsion speed 4ml / h, the spinning nozzle is immersed 0.5cm below the surface of the water bath. Set a 90° ultraviolet point light source at a distance of 6mm from the spinneret, with a wavelength of 400nm, set a drum with a diameter of 6cm at a linear speed of 400m / h, and collect the nascent hydrogel fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com