Elastic butterfly optical cable

A butterfly optical cable and elastic technology, applied in the field of elastic butterfly optical cable, can solve the problems of poor resilience, small fiber diameter and poor toughness of the optical cable, and achieve the effect of soft bending resistance, low line attenuation and excellent bending resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

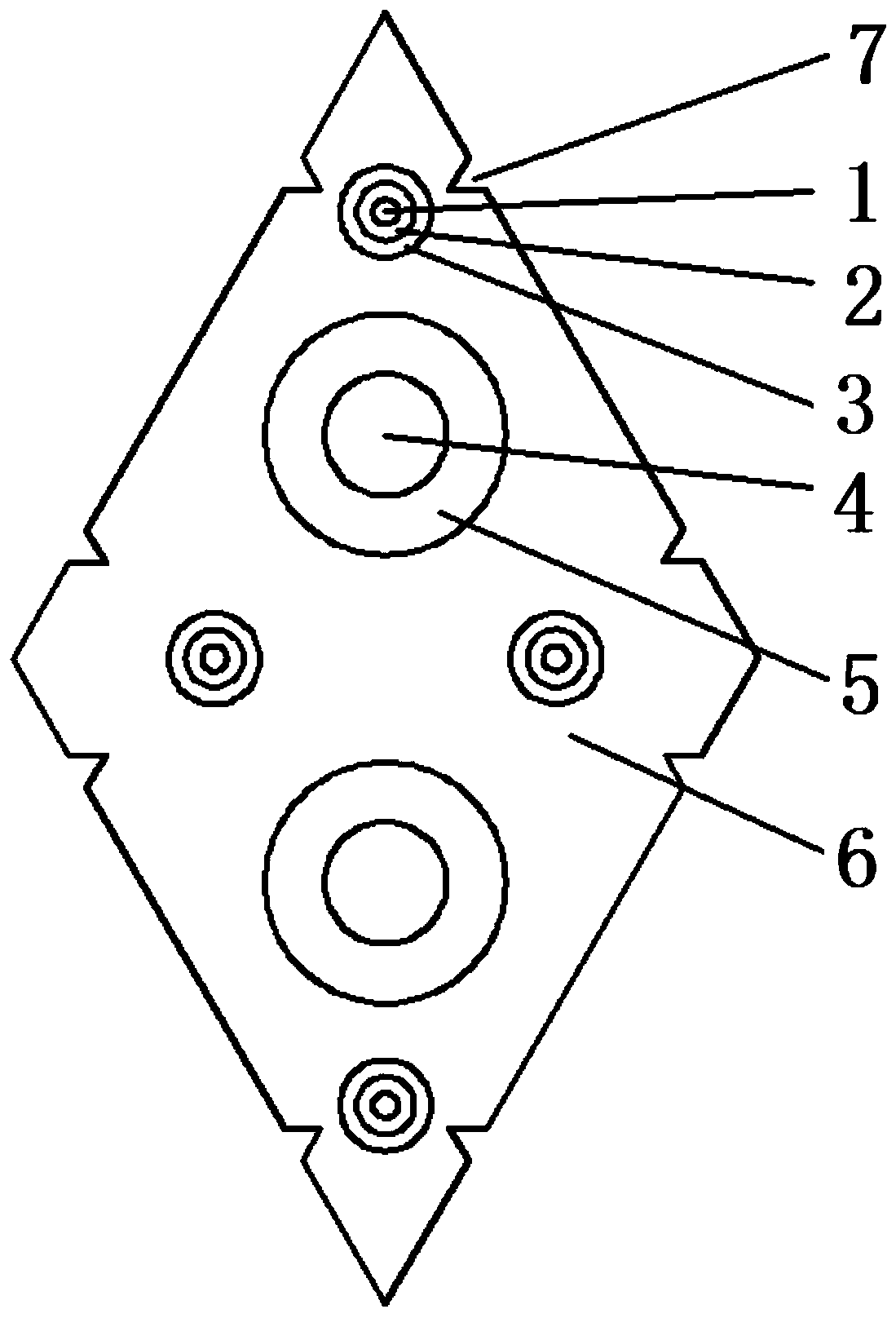

[0024] This embodiment is an elastic butterfly cable, figure 1 It is a cross-sectional schematic diagram of an elastic butterfly cable. An elastic butterfly optical cable includes an optical fiber unit, a strength member unit and an outer sheath 6; the optical fiber unit is coated with an optical fiber coating layer 2 on the surface of the optical fiber 1, and the tight sleeve layer 3 is extruded on the optical fiber coating layer 2 to form a circular shape Cross-section optical fiber unit; the strength member unit is a highly flexible circular cross-section strength member 4 whose surface is coated with a layer of strength member cushion 5 to form a circular cross-section strength member unit; the outer sheath 6 is diamond-shaped The elastic outer sheath of the diamond-shaped cylinder in cross section, the short diagonal length of the rhombus, that is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Opening width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com