Wet-type multi-disc brake for heavy truck

A brake, wet technology, applied in the direction of brake type, axial brake, brake components, etc., can solve the problems of tire blowout, fire and combustion, and unsatisfactory braking performance, and achieve the effect of solving vehicle accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For ease of understanding, the technical solutions of the present invention are further specifically described below in conjunction with the accompanying drawings and through embodiments:

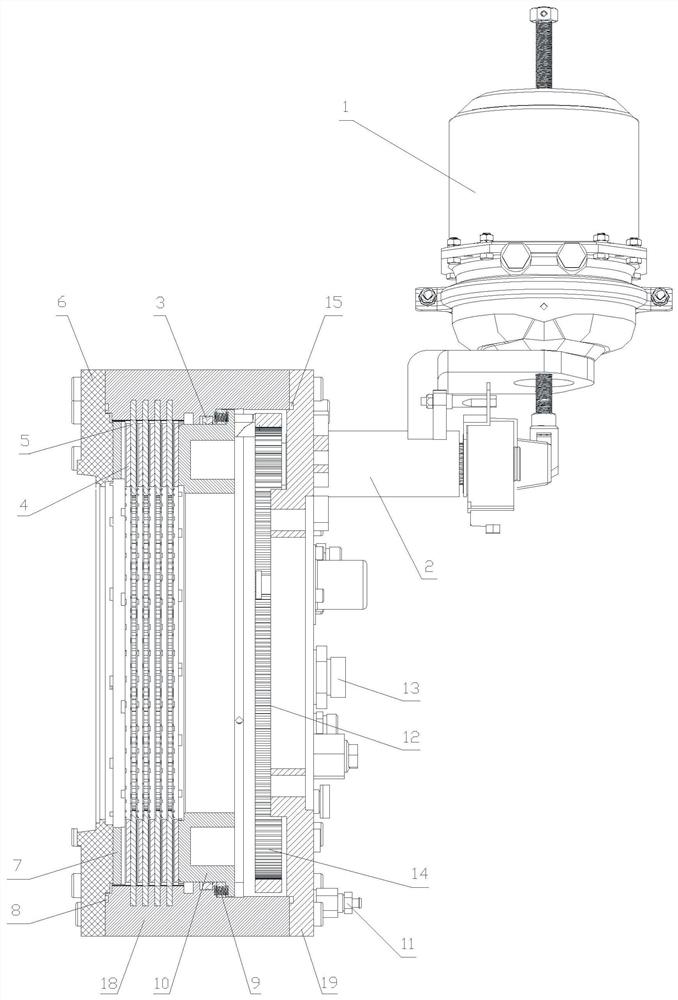

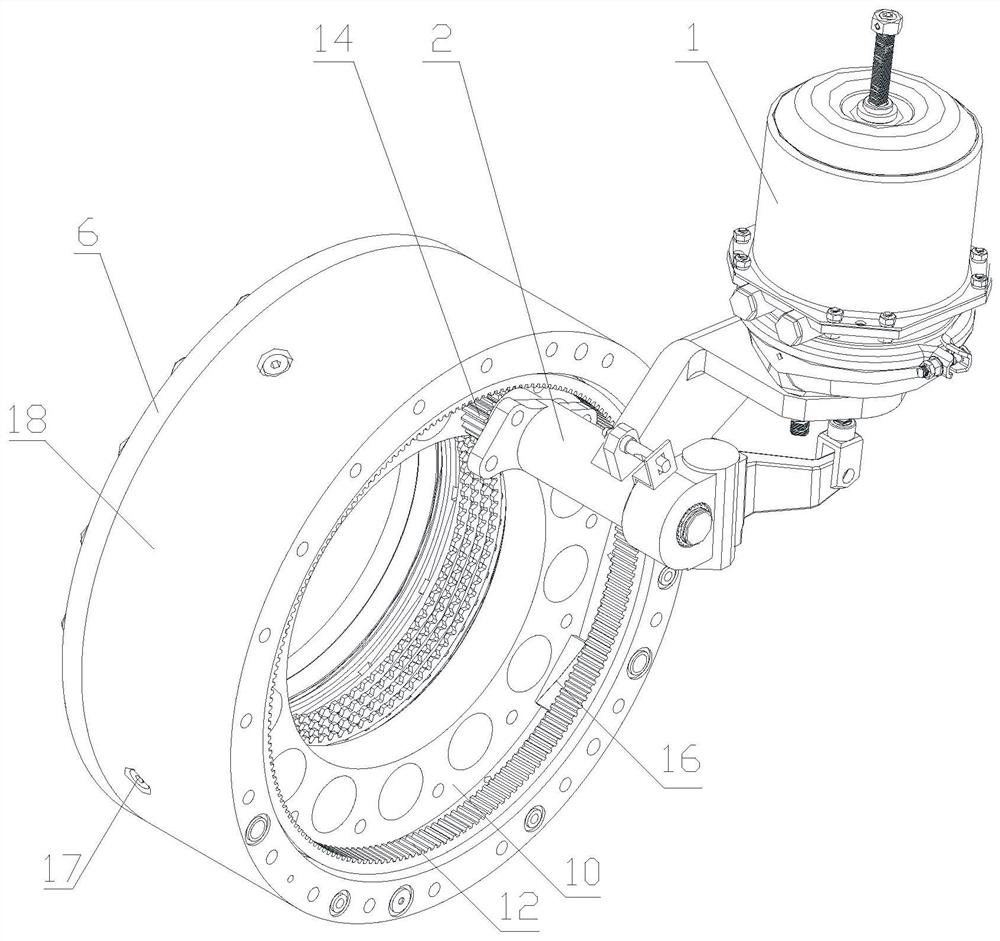

[0026] like figure 1 and figure 2 As shown, a wet multi-disc brake for heavy trucks includes a composite air chamber 1, a composite air chamber support frame 2, a dynamic friction disc 4, a static friction disc 5, an outer end cover 6, a fixed ring 7, a return spring 9, and A moving piston 10, a rotating disc 12, a power transmission gear shaft 14, an inclined plane transmission assembly 16, a body 18 and an inner end cover 19.

[0027] The outer end cover 6 is detachably arranged on the outer side of the main body 18 through bolts. A sealing ring 2 8 is arranged between the outer end cover 6 and the body 18 .

[0028] The inner end cover 19 is detachably arranged on the inner side of the main body 18 through bolts. A sealing ring 3 15 is arranged between the inner end cover 19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com