Vehicle light guide tail structure and vehicle light guide

A light guide and vehicle technology, applied in the field of vehicle light guide tail structure, can solve the problems of reducing the light-emitting length of the light guide, limiting the sense of the light line, and the bright spots cannot be blocked, etc., to optimize the lighting uniformity, eliminate bright spots, and eliminate bright spot defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

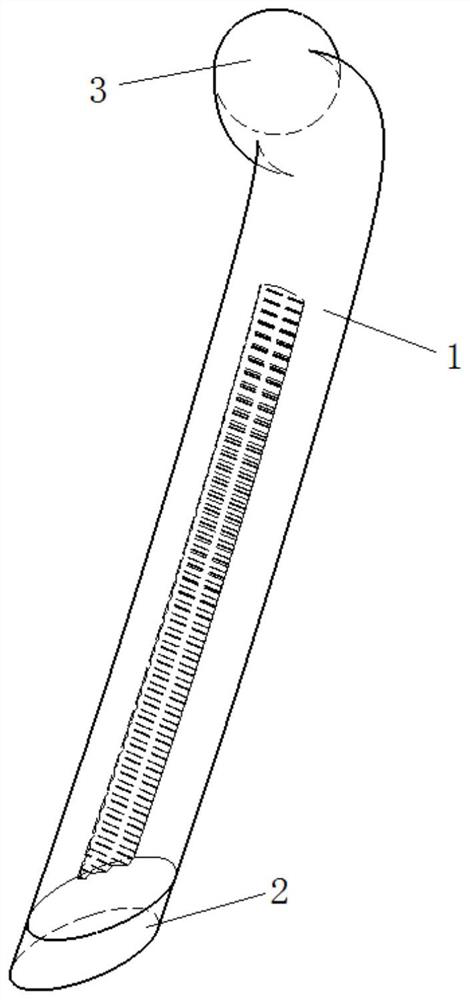

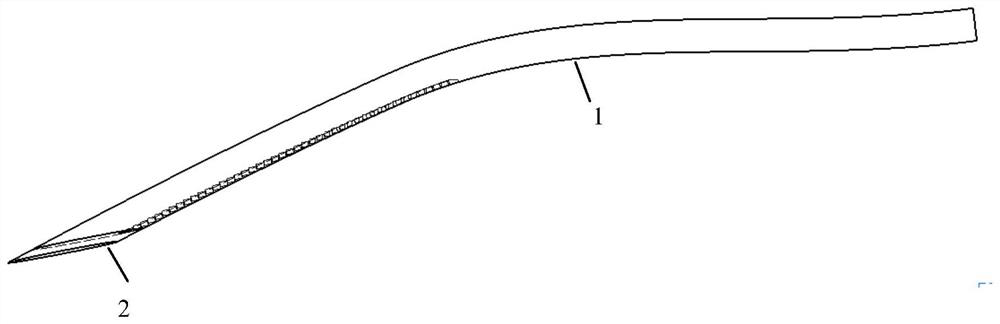

[0023] see Figure 1-Figure 4 , a light guide tail structure for vehicles, comprising a long light guide body 1, the end of the light guide body 1 away from the light source has a light guide tail 2 connected with the light guide body 1 by two-color injection molding; the light guide tail 2. Light absorbing materials or discrete materials with good scattering properties are used; the light guide tail 2 has a thickness of 1-5 mm.

[0024] In this embodiment, as a further preference, the thickness of the light guide tail part 2 is 2mm, and the tolerance is 10%.

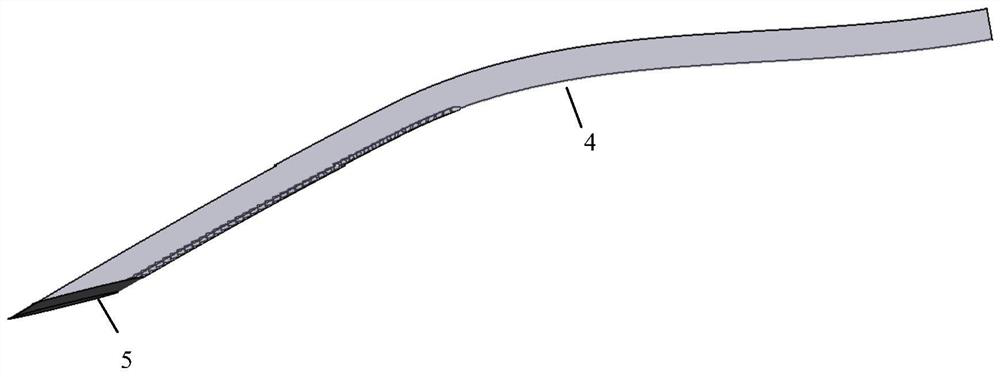

[0025] In this example, if image 3 As shown, the light guide tail 2 is made of black injection molding material 5 , and it is a better solution to choose black injection molding material 5 . by image 3 For example: the main body of the light guide is made of LC1500 transparent mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com