Lamination control device and lamination control method

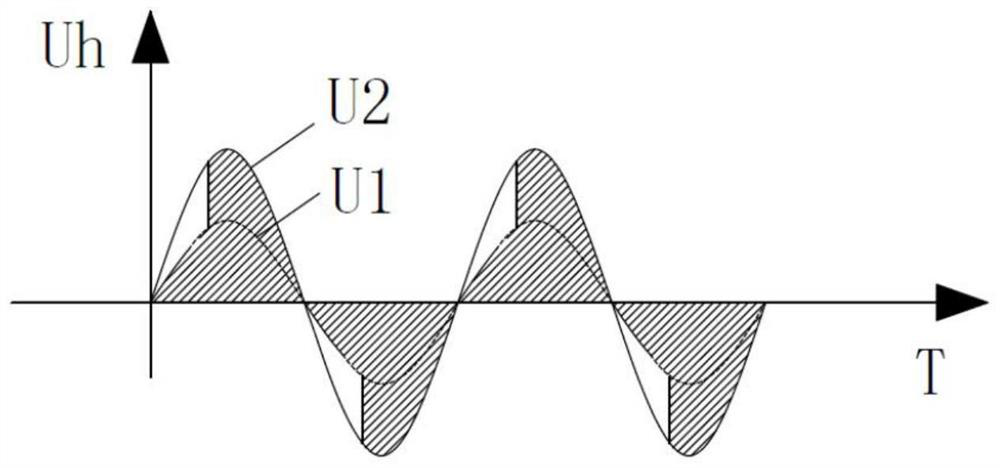

A control device and control method technology, applied in the direction of harmonic reduction device, output power conversion device, high-efficiency power electronic conversion, etc., can solve the problems of grid harmonic pollution, grid pollution, waveform damage, etc., and improve the power factor of the grid , obvious cost advantage, simple and reliable circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific drawings and embodiments.

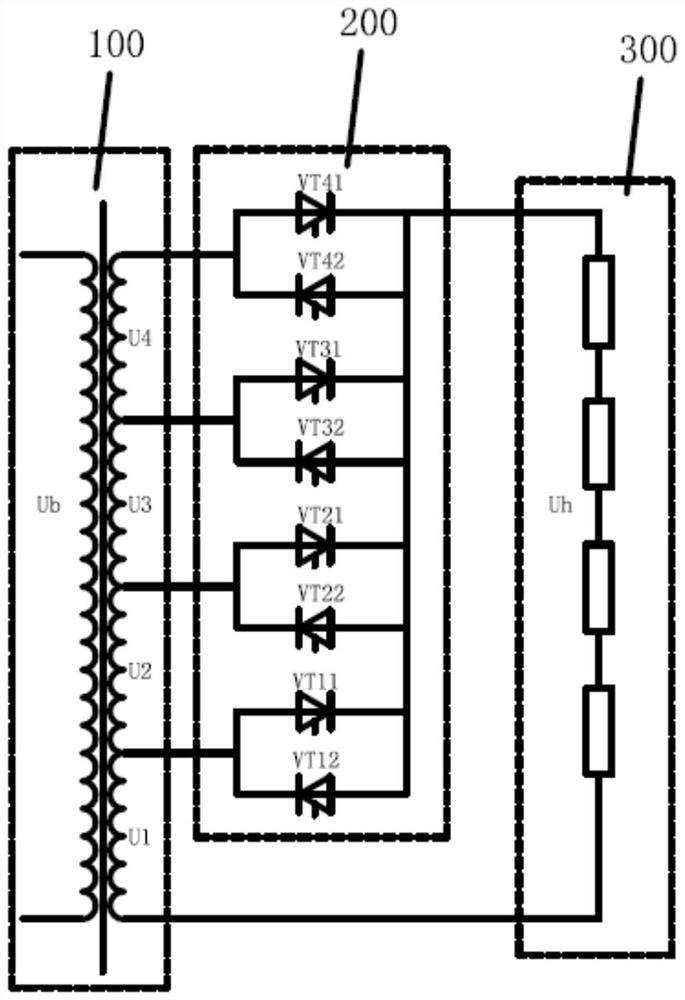

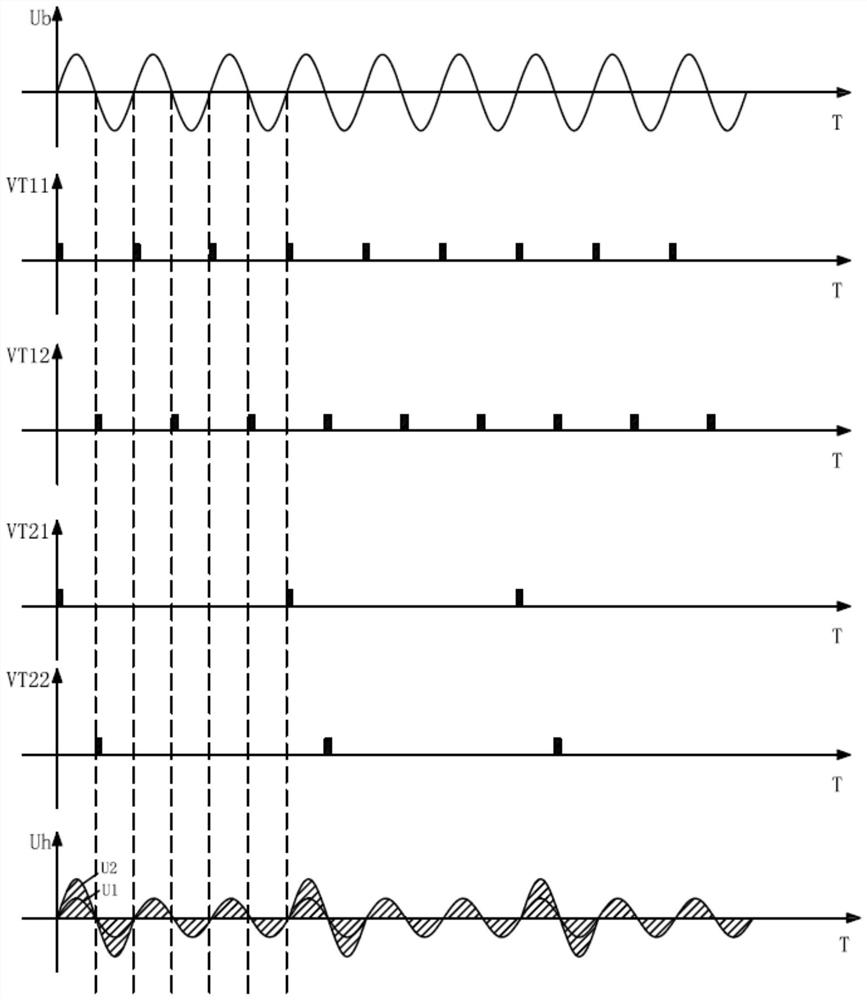

[0039] The embodiment of the present invention proposes a stack control device, such as figure 2 As shown, it includes: a controller, a transformer 100, and multiple sets of thyristors 200; in this embodiment, the electric heater 300 is used as a load; the stack control device needs to control the actual power of the electric heater 300 to meet different heating requirements; the controller is in figure 2 Not shown in the picture, hereby explain;

[0040] The transformer 100 includes a primary and a secondary, and the secondary of the transformer 100 is provided with a plurality of taps of different voltage levels and a reference terminal; figure 2 In the circuit, the secondary of the transformer 100 has taps of four different voltage levels, the voltage of each tap is U4>U3>U2>U1; the primary input voltage of the transformer 100 is Ub;

[0041] One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com