Dry type connecting device used for fabricating type composite wall vertical seam

A technology for connecting devices and composite walls, applied to walls, structural elements, building components, etc., can solve the problems of low installation efficiency and difficult post-earthquake repair, and achieve the effects of easy assembly and installation, easy post-repair, and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

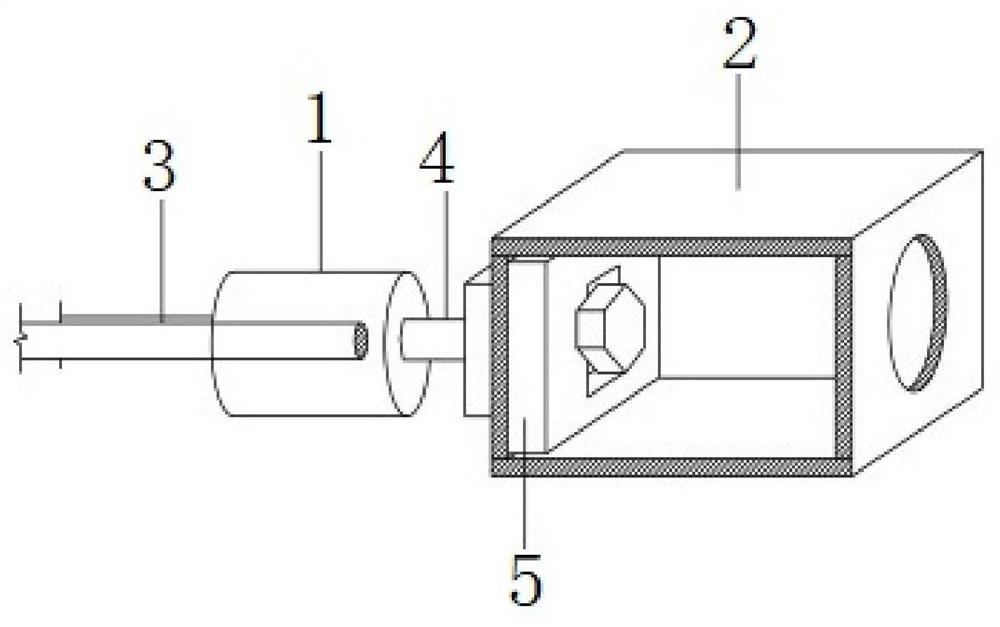

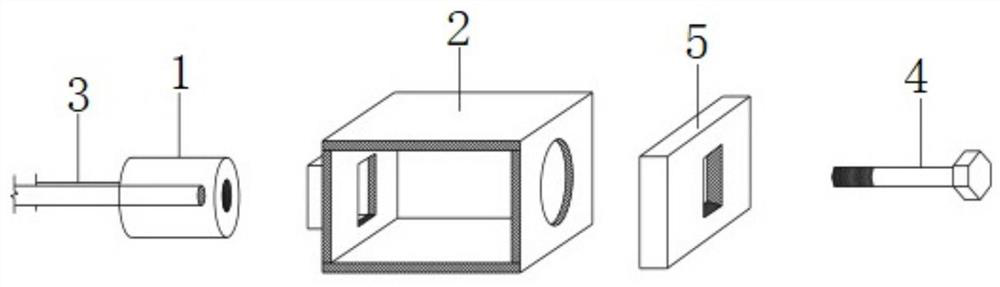

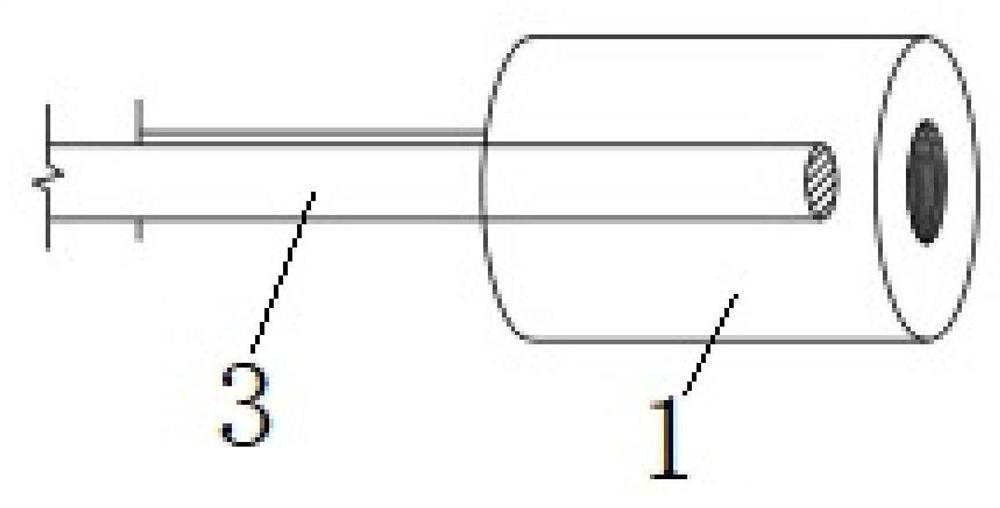

[0057] This embodiment provides a dry connection device for vertical joints of prefabricated composite walls, which is mainly suitable for multi-layer and low-level prefabricated building composite wall structures. The dry connection device is used to prefabricate two adjacent Wall panels are connected; firstly, the position of the dry connection device is determined according to the structural design, which is generally located in the middle rib beam of the prefabricated composite wall panel near the end of the vertical seam; the dry connection device includes a connection sleeve, a connection box, A number of anchoring steel bars, high-strength bolts, backing plates and caulking materials; the connecting sleeve is buried horizontally at the end of the first wall, one end of the connecting sleeve extends into the first wall, and the other end is connected to the end of the first wall Flush; the connection box is buried horizontally at the end of the second wall, and the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com