A method and system for controlling the main steam temperature of a power generation boiler based on multivariable decoupling

A multi-variable decoupling, power generation boiler technology, applied in the field of thermal power generation boiler combustion optimization, can solve problems such as unfavorable engineering on-site debugging, no consideration of the furnace, strong case-by-case, etc., to achieve easy on-site debugging, good application conditions, and labor saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

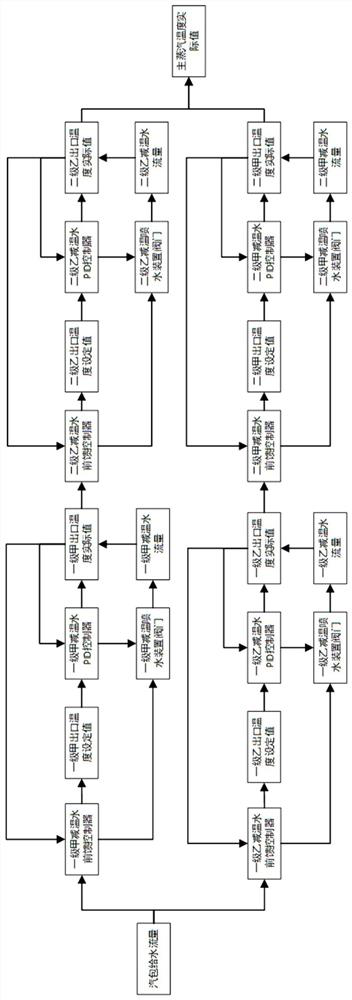

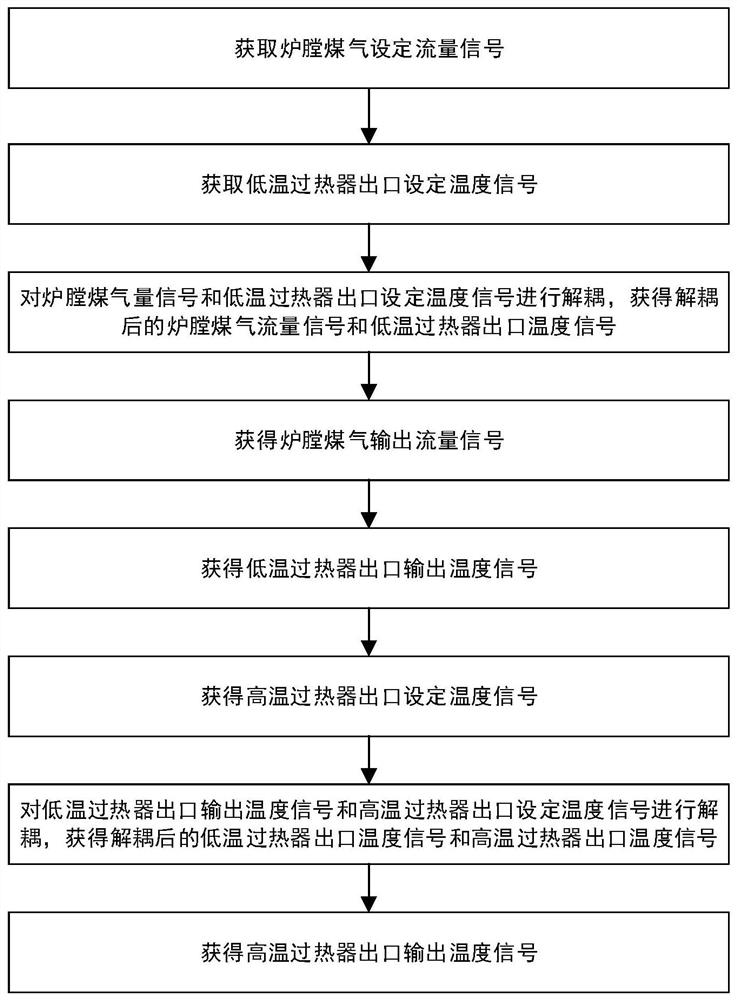

[0035] A kind of main steam temperature control method of thermal power generation boiler, the obtained signal is decoupled first, and the output signal after decoupling is controlled by a feed-forward-feedback composite controller, and then the output signal is controlled by adjusting the signal inlet valve, such as Figure 1Schematic diagram of the boiler main steam temperature control structure shown, in the boiler soda system, generally divided into two lines A and B for controlling the main steam temperature, the two structures are the same, the present embodiment takes a line as an example for specific description.

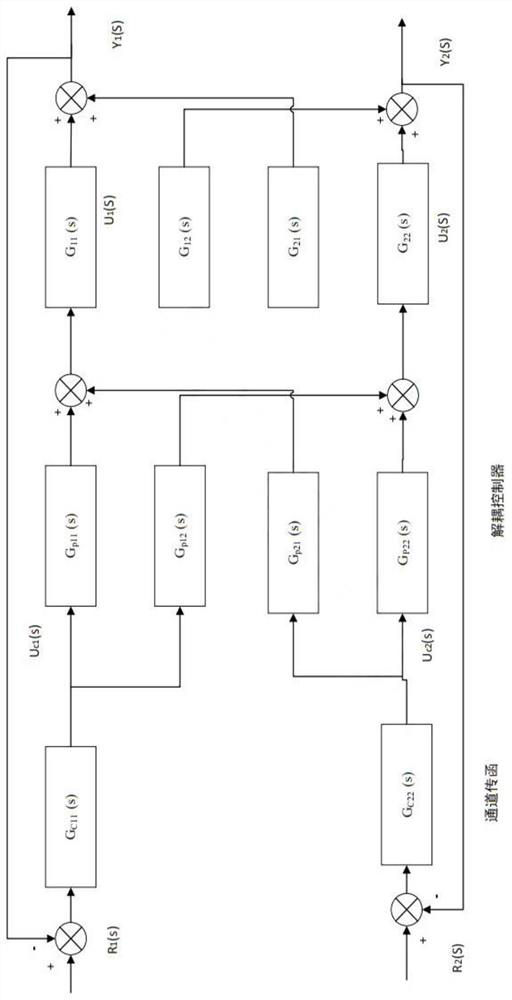

[0036] The amount of gas in the furnace chamber will have an impact on the temperature of the low temperature superheater and the temperature of the high temperature superheater, that is, the main steam temperature of the low temperature superheater outlet temperature and the main steam temperature of the high temperature superheater will have a coupling effect. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com