Flexible resistance sensor

A resistance sensor, flexible electrode technology, applied in the direction of instruments, measuring devices, measuring force, etc., can solve the problems of not easy to recover, easy to deform, easy to collapse, etc., to achieve the effect of not easy to collapse, not easy to deform, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

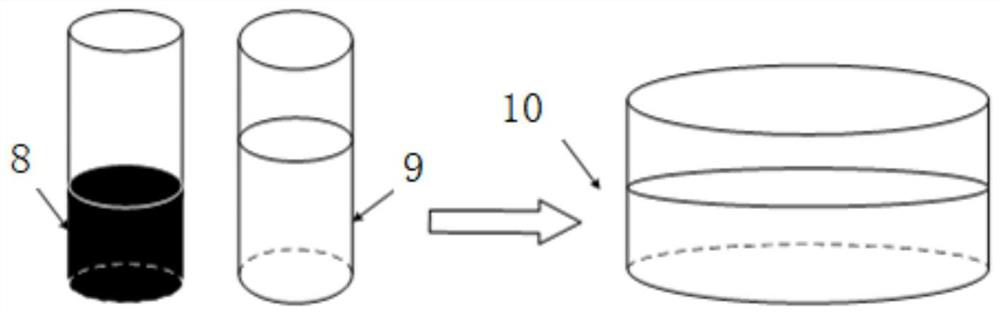

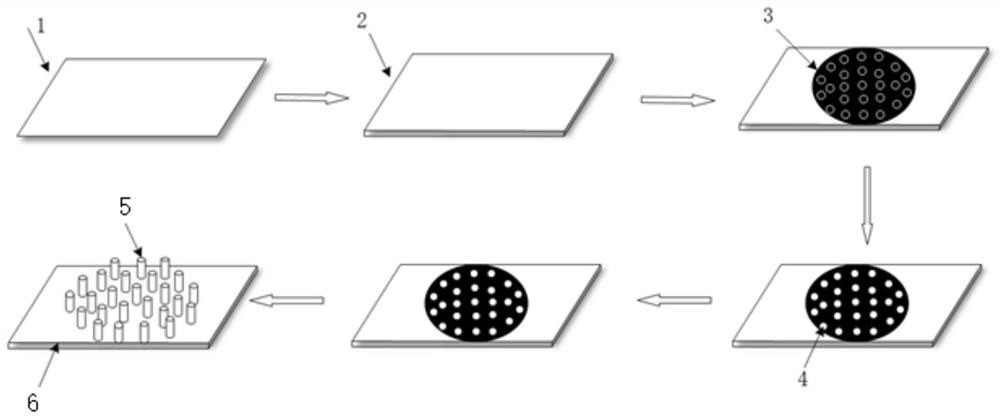

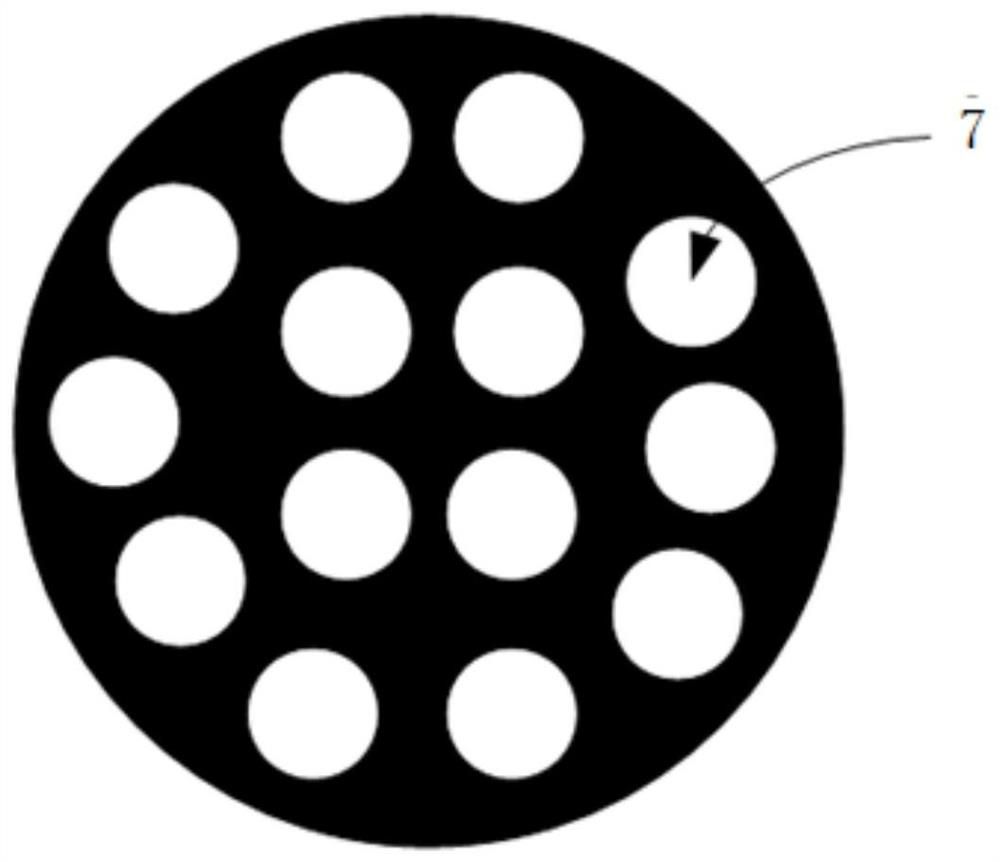

[0025] Such as Figure 1-5 As shown, the high-sensitivity flexible resistance sensor provided by the present invention includes a PDMS flexible electrode doped with carbon nanotubes with a columnar microstructure stacked up and down together, and the PDMS flexible electrode is made in the following manner:

[0026] First, a mixed PMDS sample is prepared. Due to the small Young's modulus of the commonly used PDMS DC184, there may be some difficulties in the preparation of the columnar microstructure. Since the height of the columnar structure will affect the sensitivity of the sensor, the mixed rubber samples of PDMS DC184 and PDMS SE1700 should be prepared according to the desired s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com