Fault location method and system for high voltage direct current transmission line and direct current transmission line

A technology for direct current transmission lines and transmission lines, applied in the fault location of high-voltage direct current transmission lines, in the field of direct current transmission lines, can solve the problems of fault location dead zone and affect the accuracy of fault location, and achieve the goal of shortening the distance and eliminating the fault location dead zone Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A fault location method for a high-voltage direct current transmission line provided by the present invention includes:

[0066] 1. Obtain the measured values of electrical quantities at multiple measurement points on the DC transmission line. The measured values of the electrical quantities are current measurement values or current measurement values and voltage measurement values.

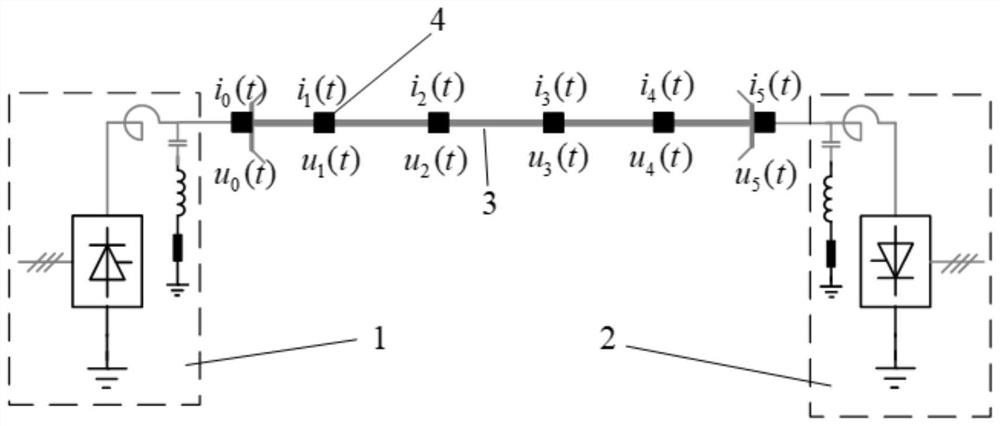

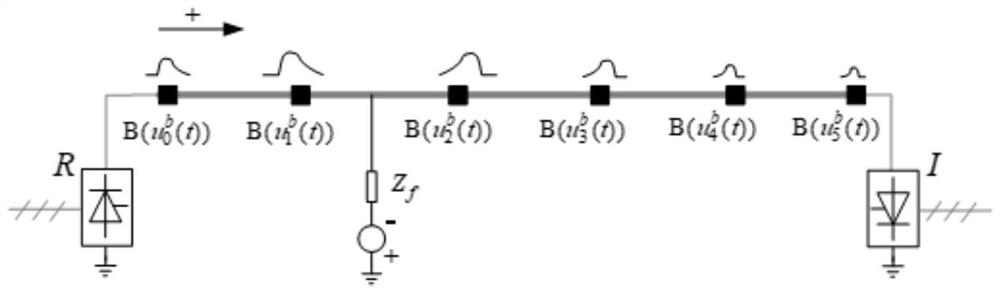

[0067] Such as figure 1 As shown, the HVDC transmission system includes a rectifier station 1, an inverter station 2, and a DC transmission line 3 connecting the rectification station 1 and the inverter station 2. The quantity measuring device 4 takes the installation position of each electrical quantity measuring device 4 as a measuring point, and obtains the voltage measurement value and current measurement value or current measurement value of each measurement point through the electrical quantity measurement device 4 . The measuring points on the direct current transmission li...

Embodiment 2

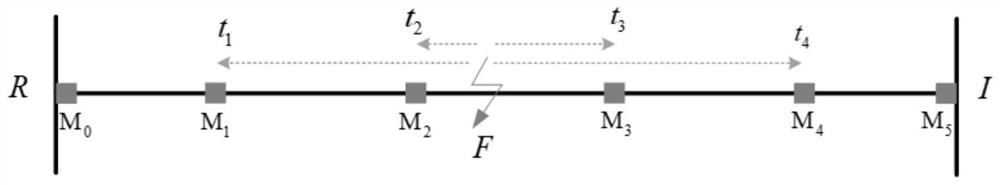

[0115] In order to take into account both economy and positioning accuracy, the total number of electrical quantity measuring devices in this embodiment is 6, such as figure 1 As shown, there is one at the head end and one at the end of the DC transmission line (the corresponding measurement point is M 0 , M 5 ), and set 4 along the DC transmission line in sequence (the corresponding measurement points are M 1 , M 2 , M 3 , M 4 ), and the measurement point M 1 , M 2 , M 3 , M 4 The distances from the head end of the DC transmission line are 0.2L, 0.4L, 0.6L and 0.8L respectively. This setting can ensure that when any point of the transmission line fails, the maximum distance between the measurement point and the fault point is limited within 0.2L, which can effectively improve the accuracy of the current measurement value or the initial wave head identification of the voltage reverse traveling wave, and improve the Fault location accuracy. In this embodiment, the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com