A bird repelling device for electrical equipment

A kind of power equipment and bird repelling technology, which is applied in the installation, application, and overhead installation of cables, etc., can solve the problems of easy threat to the life safety of flying birds, the influence of surrounding people, and poor bird repelling effect, so as to avoid energy loss and ensure life safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

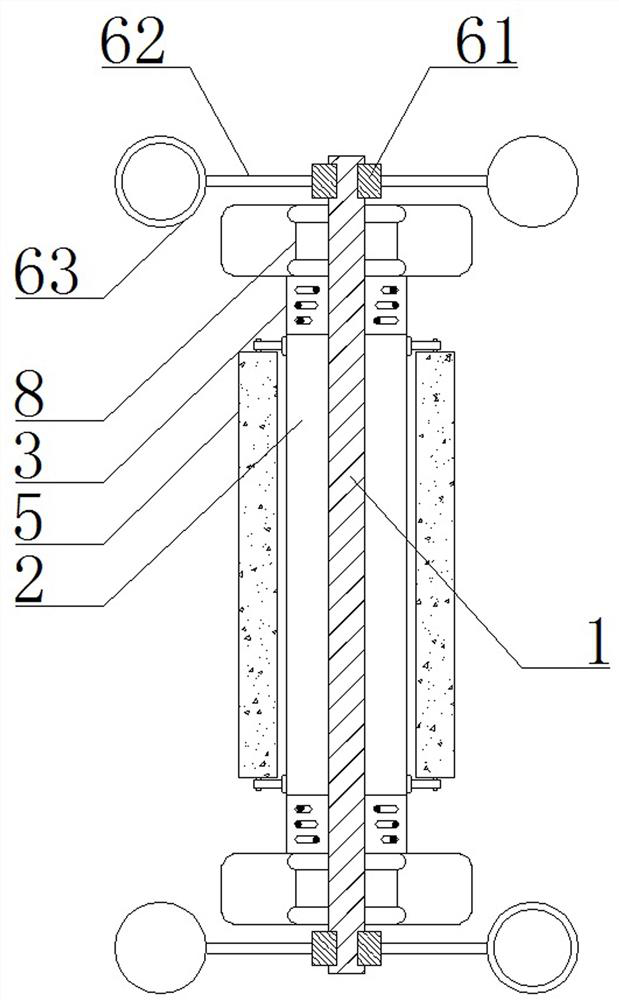

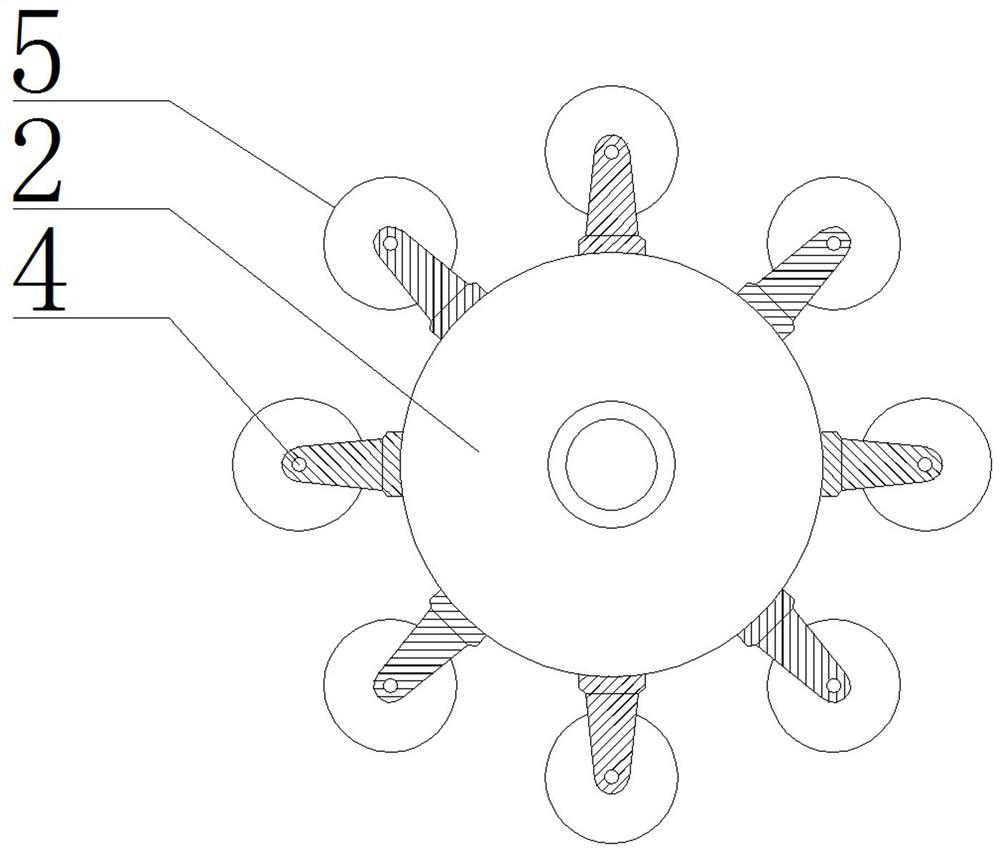

[0029] see Figures 1 to 4 , a bird repelling device for electric equipment, comprising a plurality of groups of automatic bird repelling mechanisms arranged side by side, the bird repelling mechanism comprises: a first installation shaft 1 mounted on the electrical equipment in a relative rotation manner, with relative rotation The first rotating roller 2 and the sounding mechanism 3, which are inserted on the installation shaft in a way, surround the center of the rotating roller and are evenly consolidated on the outer surface of the first rotating roller 2. The second installation shaft 4 is installed in a relative rotation manner. The second rotating roller 5 on the second installation shaft 4 is nested and installed on the pneumatic components at both ends of the first installation shaft 1 in a relative rotation manner; ;

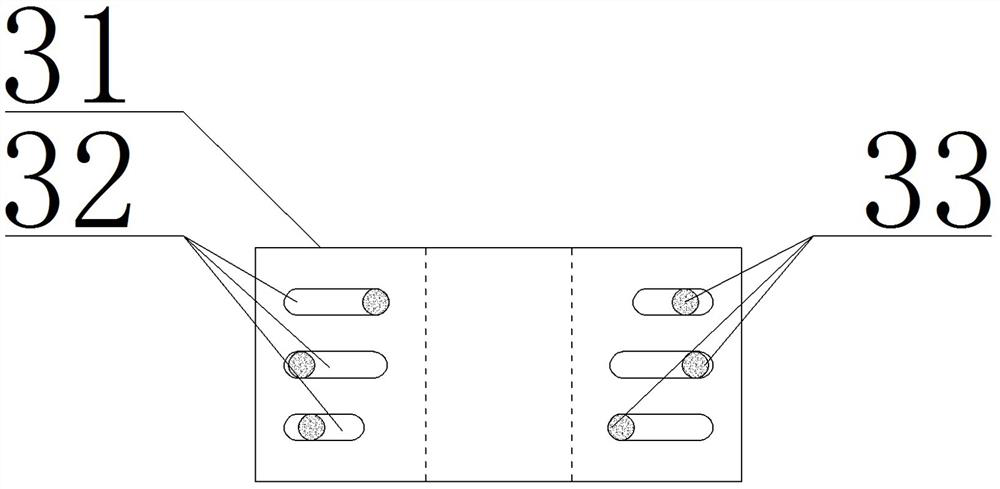

[0030] The sounding mechanism 3 includes: an installation turntable 31 that is inserted on the first installation shaft 1 in a relatively rotating m...

Embodiment 2

[0032] see Figures 1 to 4 , a further supplementary explanation is given to Embodiment 1: the collision slot 32 is set as a triangular structure as a whole, and the corner positions of the collision slot 32 are set as arc surfaces, and the number of collision slots 32 on the same level in each group of sounding mechanisms 3 is set at 3-12 Between groups, when the first rotating roller 2 drives the installation turntable 31 to rotate, the collision balls 33 arranged in the collision grooves 32 of each group fall or rise in the collision grooves 32, collide with the collision grooves 32 and emit vibration and sound, To drive off docked birds;

[0033] The number of the second installation shafts 4 arranged on each group of the first installation shafts 1 is set between 3 and 16 groups, so as to ensure that the second rotating rollers 5 are provided in a sufficient number to surround the corresponding first rotating rollers 2. Since the second rotating rollers 5 There is a cert...

Embodiment 3

[0036] see figure 1 , 6 7. Explain the arrangement of the bird repelling mechanism described in this application: when the bird repelling mechanism is arranged, the first installation shafts 1 of each group of bird repelling mechanisms are kept in parallel arrangement, and the first installation shafts 1 of each group are fixedly installed On the installation support 8, the installation support 8 is fixedly installed on the outer surface of the electric equipment, so as to effectively prevent the birds from docking on the electric equipment;

[0037] As an arrangement of the bird repelling mechanism, one or more sets of first rotating rollers 2 are installed on each set of first installation shafts 1 . When a roller 2 is rotated, sounding mechanisms 3 are fixed on both end faces of the first rotating rollers 2 corresponding to each group, so as to ensure that the number of sounding mechanisms 3 installed on each group of the first installation shaft 1 is large enough, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com