A method and system for synchronous loading and unloading of containers based on pre-storage

A loading and unloading system and container technology, applied in storage devices, loading/unloading, transportation and packaging, etc., can solve problems such as difficult to meet the requirements of efficient container loading and unloading, limit the application and development of railway logistics, and long parking time of transport trains, etc., to achieve The effect of shortening operation time, increasing flexibility and variety, and shortening downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

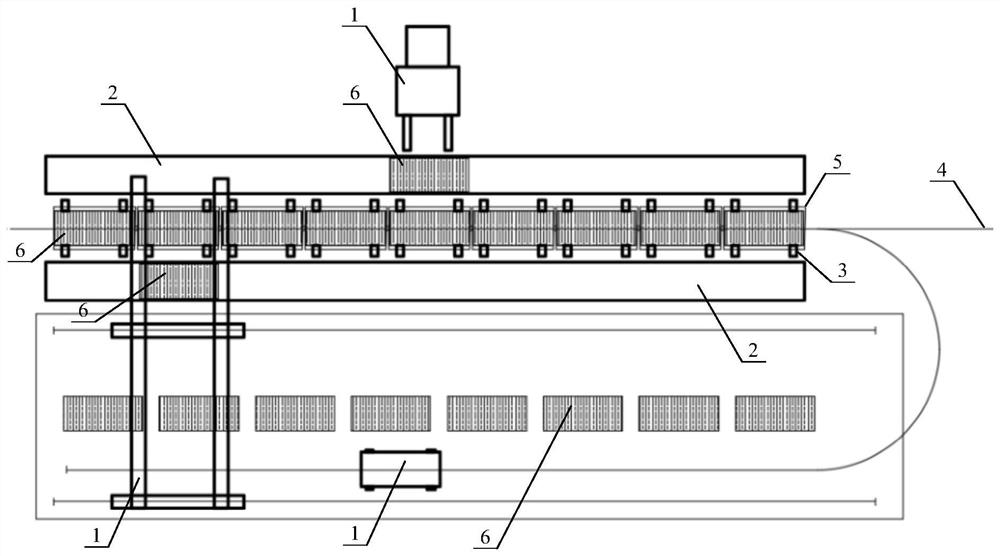

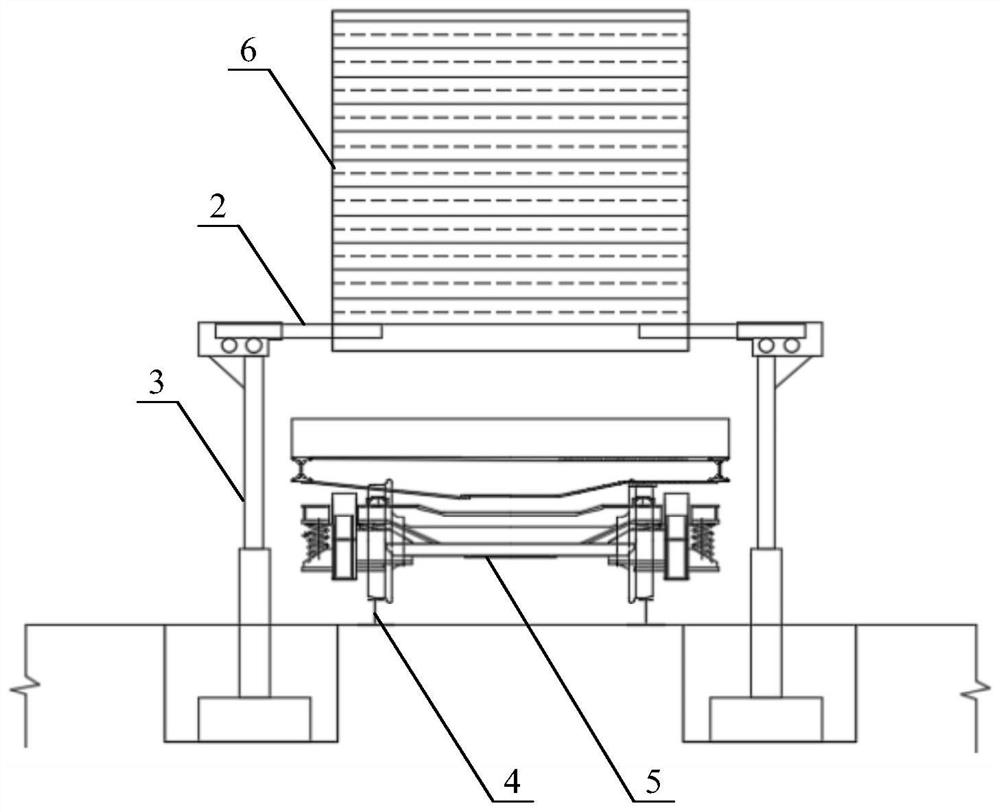

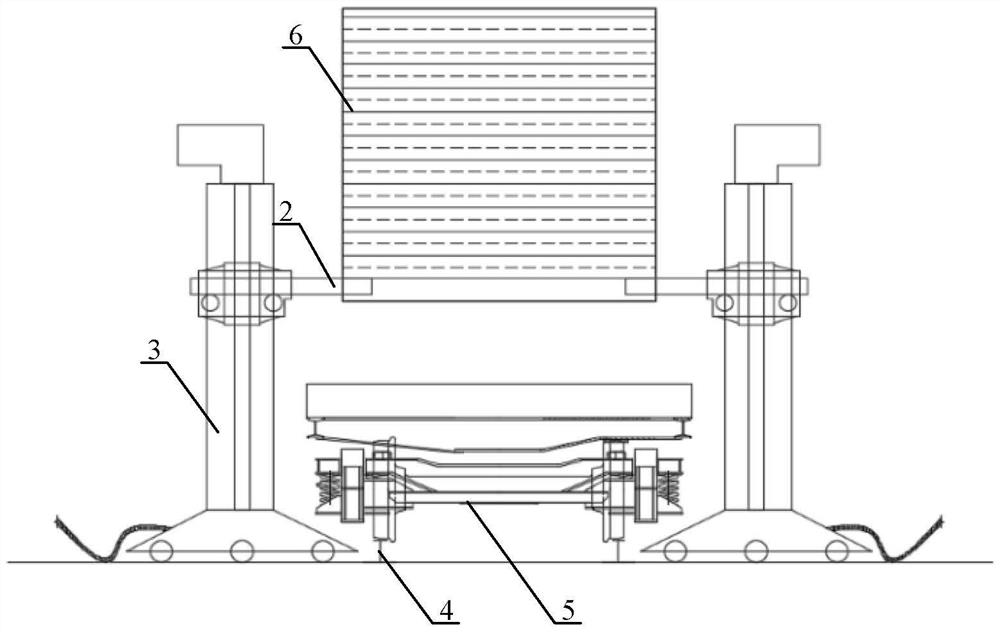

[0056] see Figure 1-11 In the preferred embodiment of the present invention, the method for synchronous loading and unloading of a whole row based on pre-stored containers is aimed at realizing the synchronous loading of a whole row of a plurality of containers 6 on each loading platform of the transport train 5 or the synchronous unloading of a plurality of containers 6 on the transport train 5. The efficiency of container 6 loading and unloading.

[0057] In order to achieve the above purpose, based on the concept of container pre-storage in the preferred embodiment of the present invention, a pre-storage device 2 and a synchronous loading and unloading device 3 are correspondingly provided along the loading and unloading line 4, and a container loading and unloading device 1 is provided corresponding to the pre-storage device 2. Utilizing the corresponding setting of the pre-storage equipment 2 along the loading and unloading line 4, the pre-storage station suitable for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com