Dust removal cover and dust removal device

A technology of a dust removal device and a dust removal hood, which is applied in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using gas flow, etc., can solve problems such as battery short circuit, poor dust removal effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the battery, the pole piece is mainly made of active materials and other components. During battery assembly, winding is usually required to form cells. In the actual production process, the pole piece is easy to carry dust and introduce it into the battery cell, resulting in a short circuit of the battery cell. Therefore, it is necessary to control the dust on the surface of the pole piece.

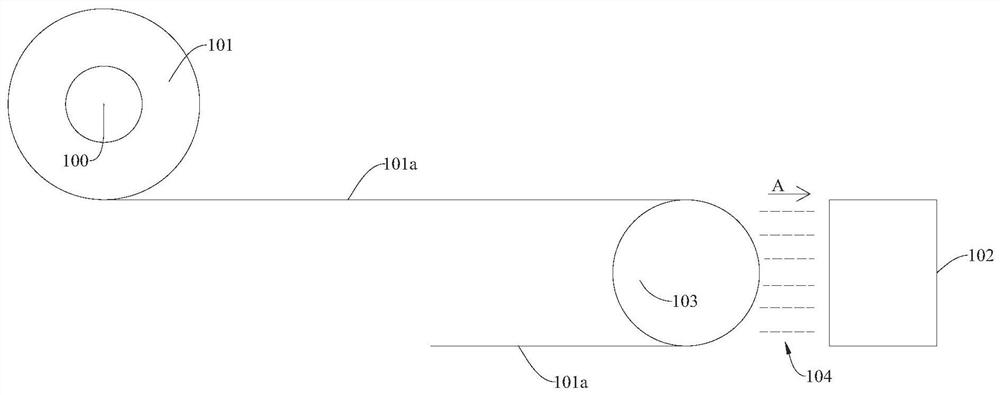

[0042] refer to figure 1 , generally, the dust removal method of the pole piece is: fix the positive electrode coil material 101a (or negative electrode coil material) on the unwinding shaft 100 and unwind it; at the same time, in the process of the coil material passing the roller 103, a vacuum cleaner 102 is arranged above the roller 103 , complete dust suction with negative pressure suction of dust 104 from the surface of positive electrode coil material 101a (wherein the suction direction A of dust is figure 1 shown).

[0043] The inventors have made efforts to improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com