Mechanism for cutting aluminum plates

A technology of cutting mechanism and aluminum plate, which is applied in the direction of metal processing machinery parts, manufacturing tools, measuring/indicating equipment, etc., can solve the problems of reduced efficiency, scratches on the edge of finished products, and oil on the end surface, so as to reduce useless consumption and improve Production efficiency, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

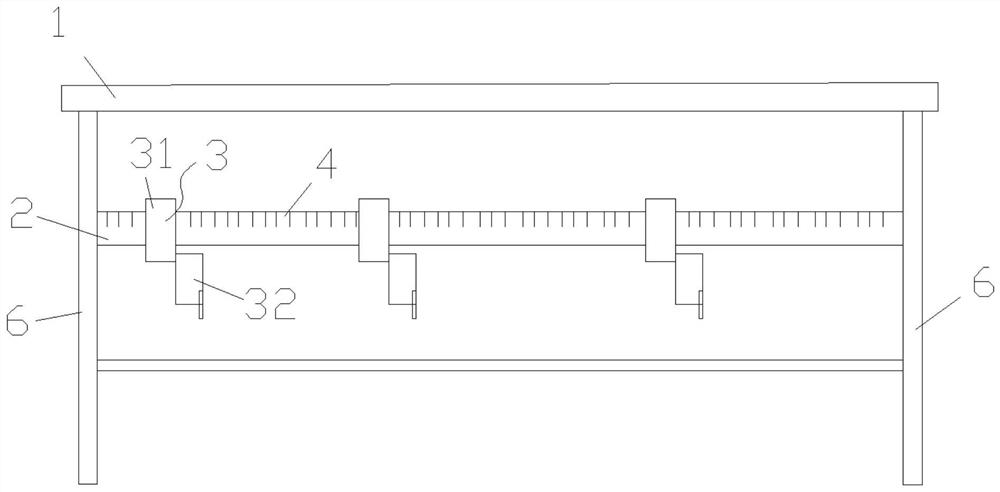

[0023] The present invention proposes an aluminum plate cutting mechanism, such as Figure 1-3 As shown, including the frame body 1, the frame body 1 is provided with four support legs 6 on the lower surface of the panel, and the four support legs 6 are respectively arranged along the width direction and the length direction, and the connection line between the vertices of the four has a rectangular structure.

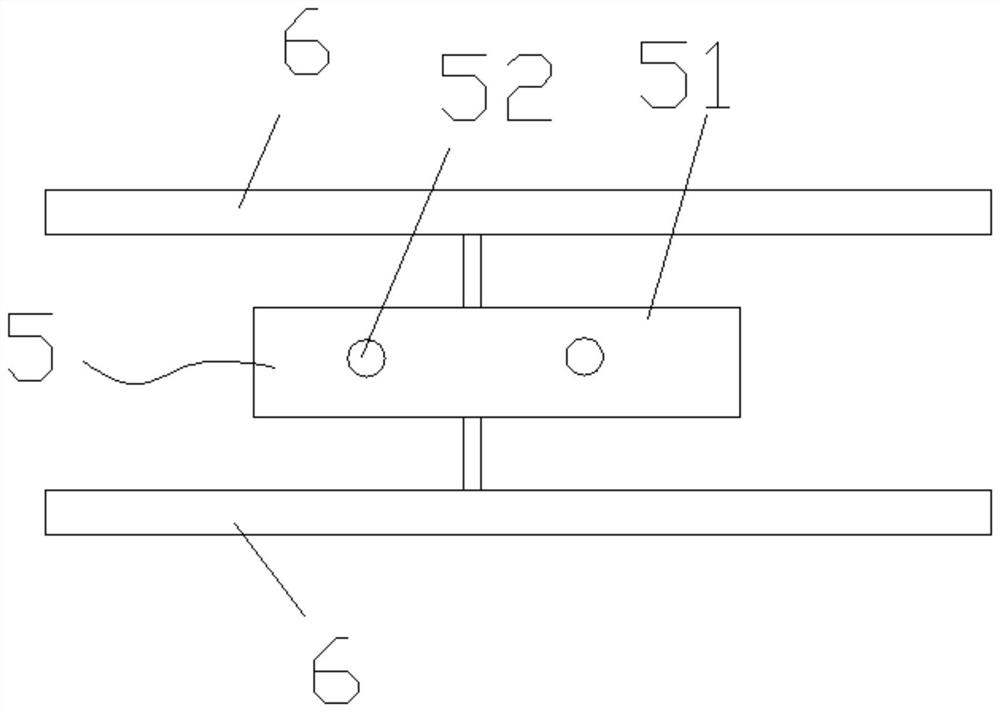

[0024] A cutting mechanism 3 and a transport mechanism 5 arranged up and down are arranged between the supporting legs 6 of the frame body.

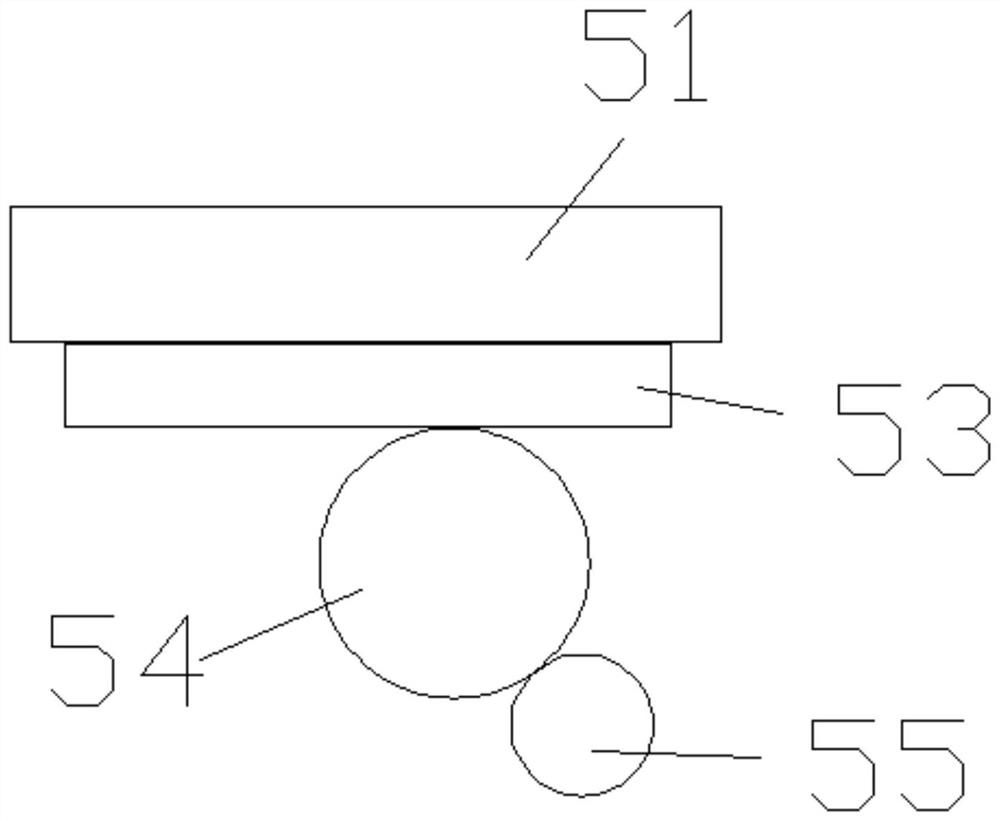

[0025] The transportation mechanism 5 includes a guide plate 51 on which an aluminum plate is placed, and a purging pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com