Hammer assembling device

An assembly device and hammer technology, applied in the direction of climate sustainability, final product manufacturing, manufacturing tools, etc., can solve the problems of high effort, low safety, easy to smash hands, etc., to prevent deviation, safety high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

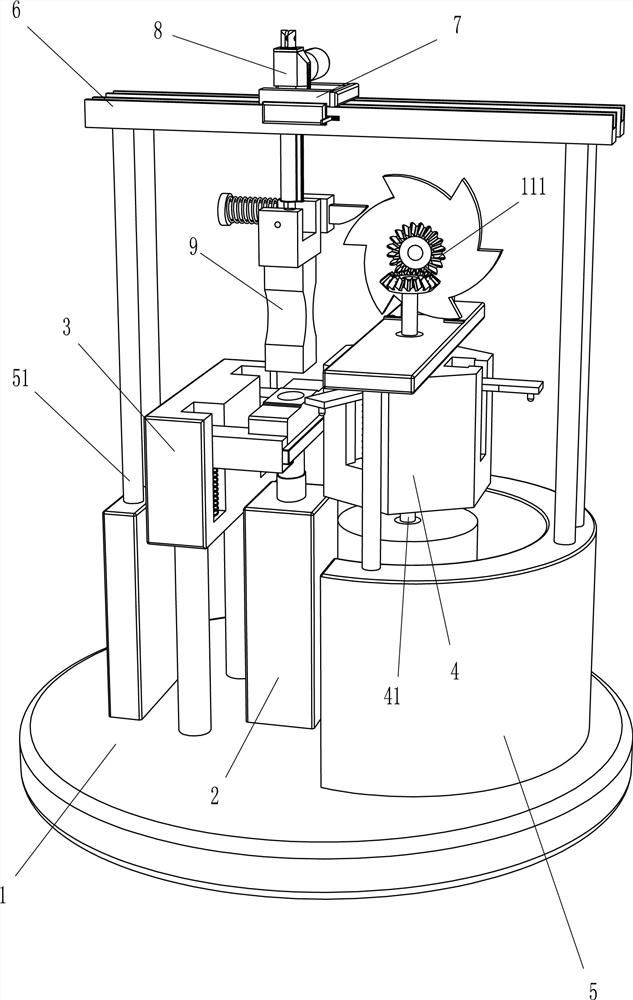

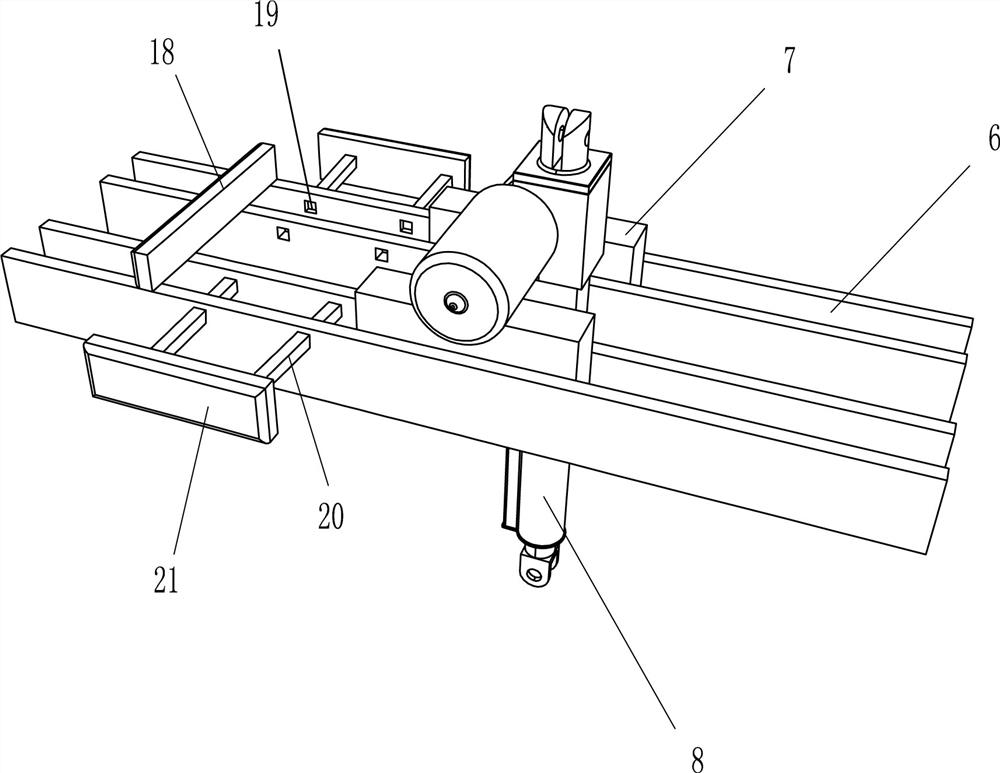

[0023] A hammer assembly device such as Figure 1-4 As shown, it includes a bottom plate 1, a placement cylinder 2, a clamping mechanism 3, an auxiliary nail placement mechanism 4, an arc seat 5, a bracket 51, a slide rail 6, a slider 7, a cylinder 8 and a hammer 9, and the top of the bottom plate 1 A placement tube 2 is arranged in the middle, a clamping mechanism 3 is provided on the left side of the top of the base plate 1, a nail auxiliary placement mechanism 4 is provided on the right side of the top base plate 1, an arc-shaped seat 5 is provided on the right side of the top of the base plate 1, and the top of the arc-shaped seat 5 and The left side of the top of the bottom plate 1 is provided with a bracket 51, two slide rails 6 are arranged on the two brackets 51, a slider 7 is slidably arranged on the slide rail 6, a cylinder 8 is arranged between the two sliders 7, and the telescopic rod of the cylinder 8 Percussion hammer 9 is arranged on.

[0024] The clamping mech...

Embodiment 2

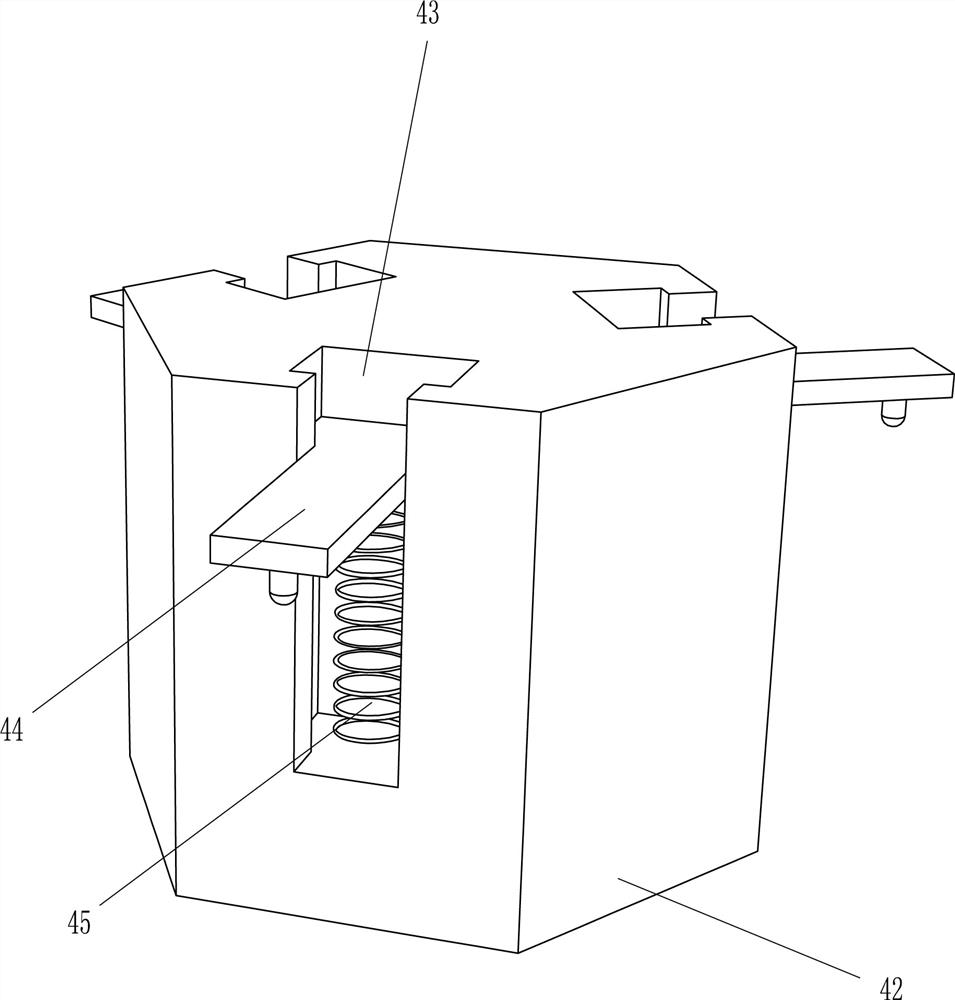

[0028] On the basis of Example 1, such as figure 1 , 2 As shown in and 5, it also includes an N-shaped frame 10, a rotating shaft 11, a bevel gear 111, a hexagonal ratchet 12, a hexagonal block 13, a shrapnel 14, a guide sleeve 15, a wedge-shaped block 16 and a third elastic member 17, arc-shaped The top of the seat 5 is provided with an N-shaped frame 10, and the vertical direction is provided with a rotating shaft 11 in the middle of the top of the hexagonal column 42. The rotating shaft 11 passes through the N-shaped frame 10, and the N-shaped frame 10 is horizontally rotatable. 10. A hexagonal ratchet 12 and a hexagonal block 13 are arranged on the rotating shaft 11 in the horizontal direction. Bevel gears 111 are arranged on the two rotating shafts 11. The two bevel gears 111 mesh with each other. The top of the N-shaped frame 10 is symmetrically provided with shrapnel 14, shrapnel 14 In close contact with the two side walls of the hexagonal block 13, a guide sleeve 15 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com