A quick cutting device for packaging production

A rapid cutting and packaging film technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of increasing production costs, cutting blade damage, and destroying packaging bags, etc., to reduce incomplete cutting and increase production Efficiency and the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

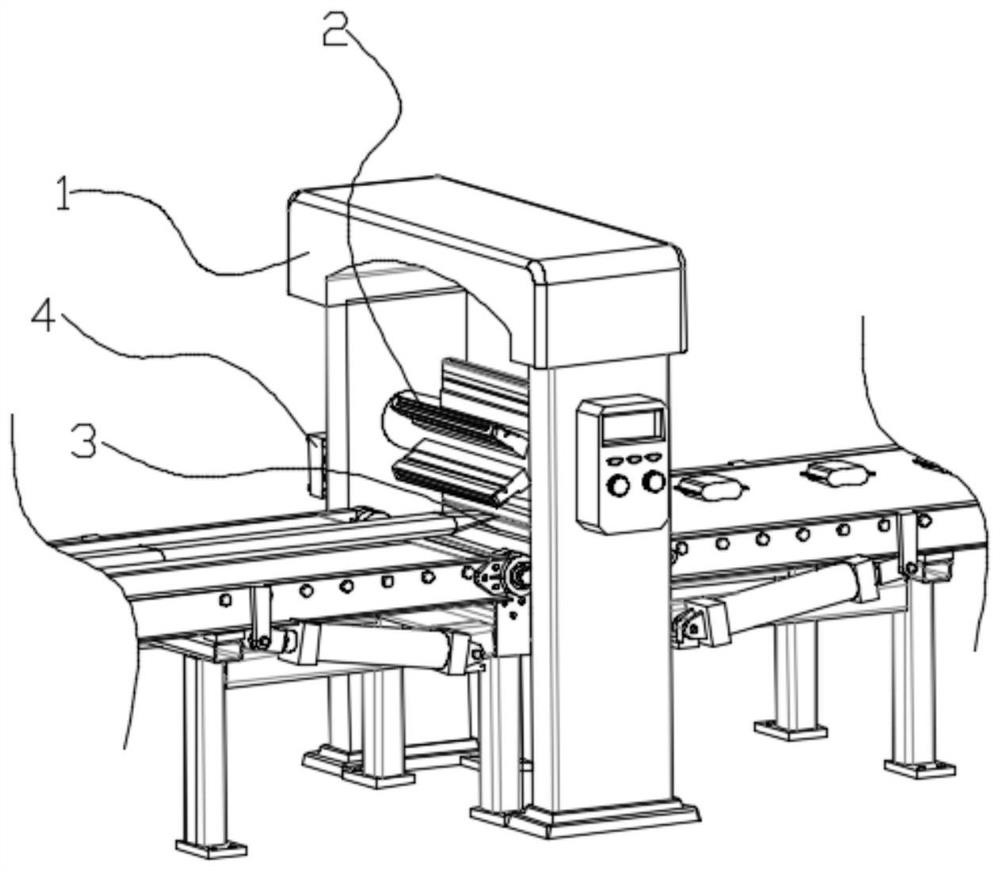

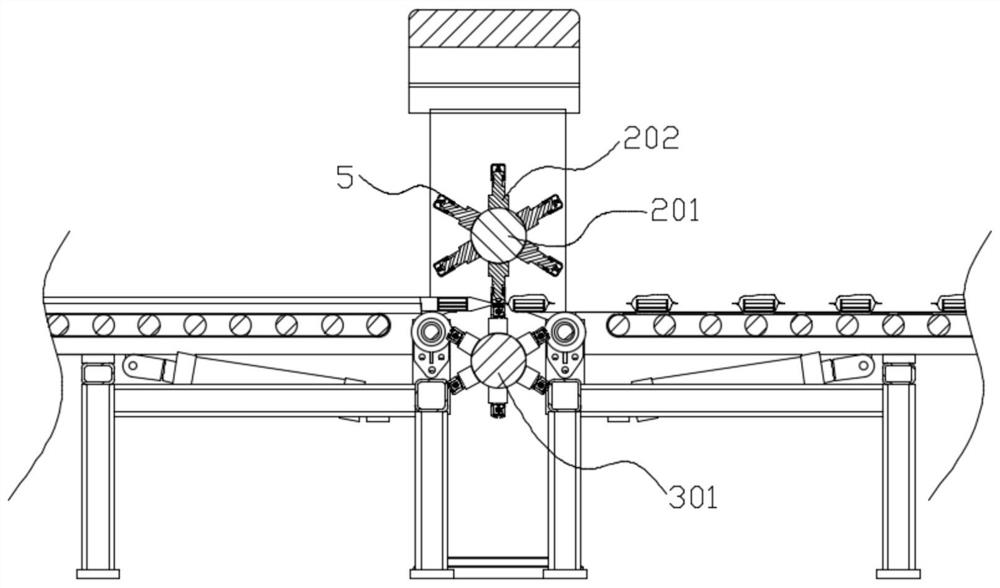

[0046] see figure 1 , in an embodiment of the present invention, a quick cutting device for packaging production, which includes: a frame 1, a cutting assembly 2 and a heating device 3, the cutting assembly 2 is rotatably connected to the middle of the frame 1, and is used to The drum packaging film of the product is cut into multiple independent packaging bags;

[0047] The heating device 3 is arranged directly below the cutting assembly 2 and is rotatably connected to the frame 1 for heating and sealing the packaging film before cutting;

[0048] The left and right sides of the frame 1 are provided with conveyor belts, the left side of the frame 1 is the feed end, the right end is the discharge end, and the two conveyor belts operate independently of each other;

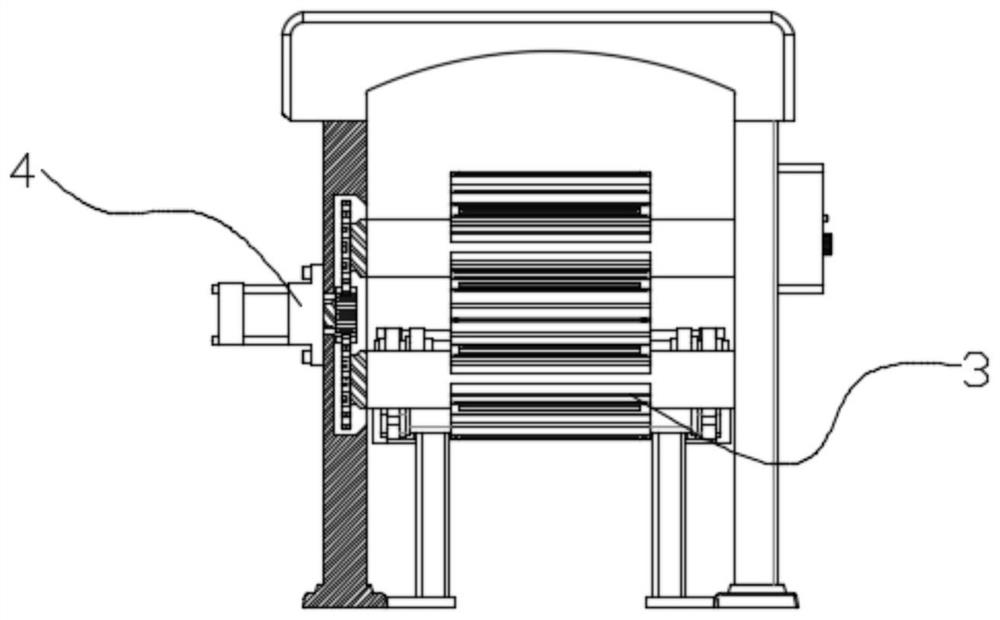

[0049] The cutting assembly 2 and the heating device 3 are respectively arranged on the upper and lower sides of the conveyor belt, and are all driven by a driving motor 4 through gears. The rotation directions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com