Float collar and rubber plug interlocking device and application method

A technology of interlocking device and rubber plug, which is used in earth-moving drilling, wellbore/well components, sealing/packing, etc., which can solve the problems of increasing the workload of drilling plugs of the well team and affecting the cementing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

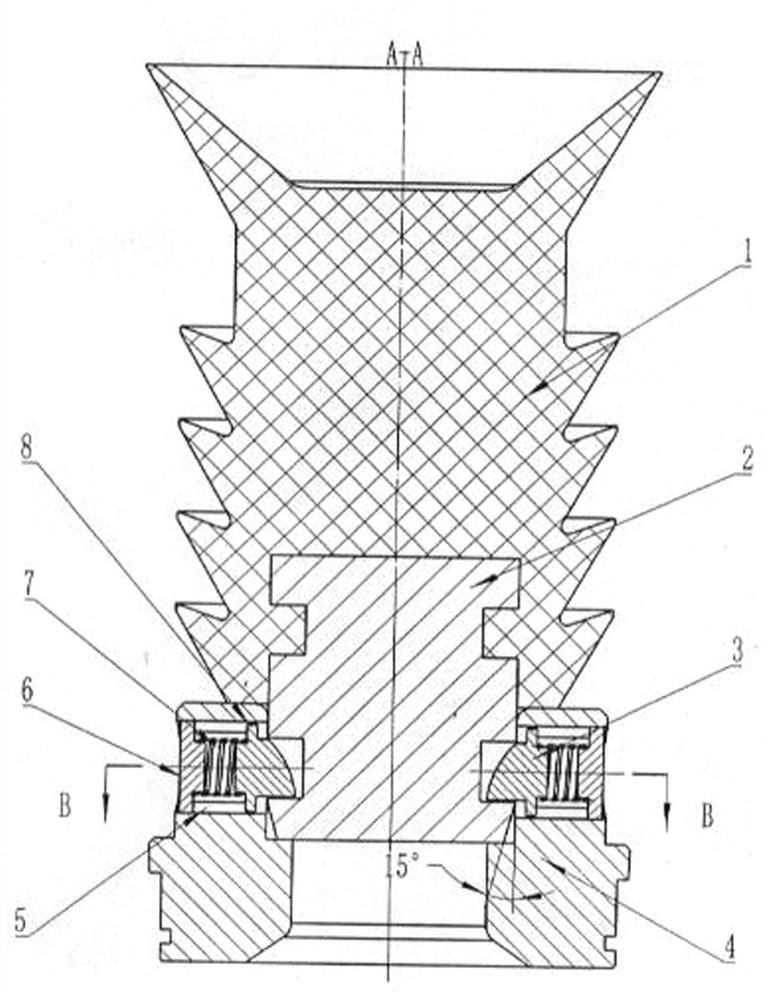

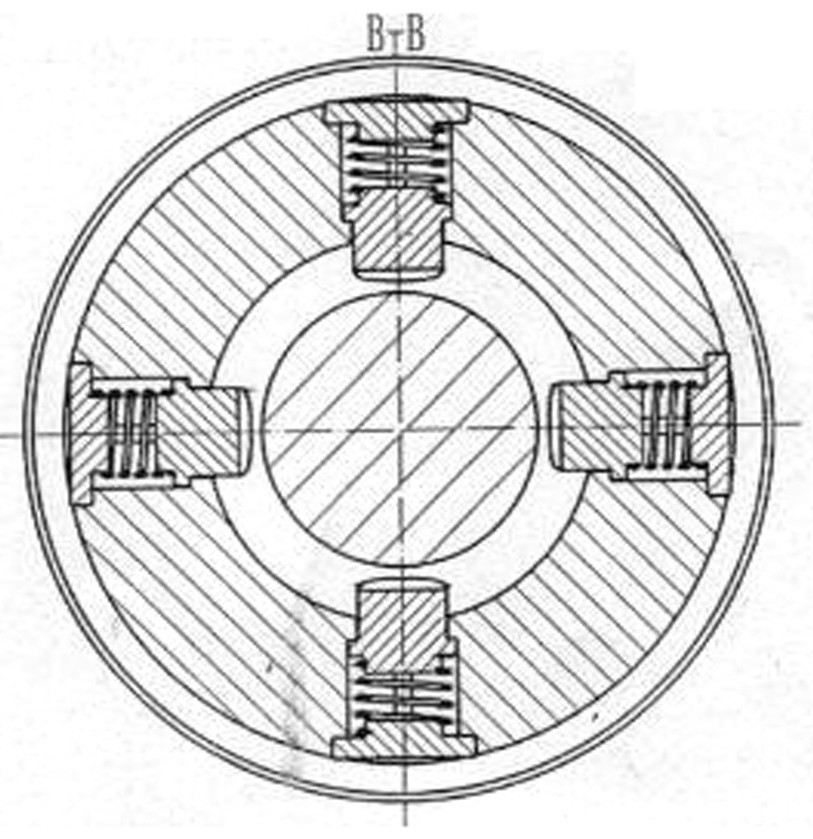

[0012] Embodiment 1. The present invention includes a rubber plug 1, a lock groove body 2, a lock pin 3, a spoiler 4, a guide groove 5, a blocking plate 6, a spring 7, and a guide key 8. The lower part of the rubber plug 1 is provided with aluminum The lock groove body 2, the lock groove body 2 is concentric with the rubber plug 1 and vulcanized at high temperature as a whole; the upper part of the spoiler 4 is provided with four retractable lock pins 3, and the guide groove 5 is set in the installation hole of the lock pin 3 , the guide key 8 is set on the lock pin 3, and the lock pin 3 does not rotate in the radial direction, thereby ensuring that the arc surface of the lock pin 3 is always upward and improving reliability; after four sets of lock pins 3 and springs 7 are installed in the hole, the blocking plate 6 Weld it on the spoiler 4 to form a new spoiler assembly, and then install the spoiler assembly into the floating hoop.

Embodiment 2

[0013] Embodiment 2, the upper part of the inner hole of the spoiler 4 is provided with R4 rounded corners, and the outer circle of the lower part of the lock tank body 2 is provided with a 15° conical surface, which is convenient for entering the spoiler 4 .

Embodiment 3

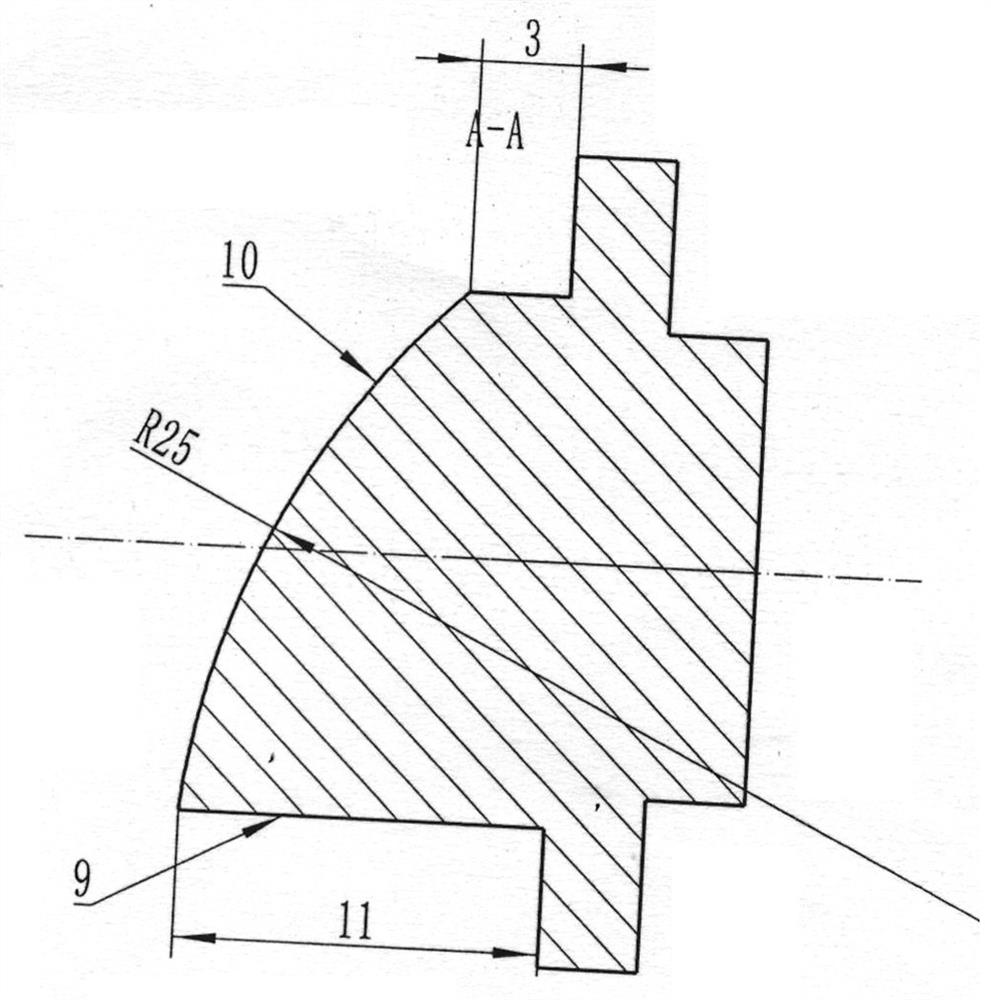

[0014] Embodiment 3, the upper part of the lock pin 3 is an R25 arc surface 10, which is convenient for the rubber plug lock groove body 2 to enter, and the lower part of the lock pin 3 is a straight face 9, which can prevent the lock pin 3 from retracting when the lower pressure increases, resulting in interlock failure Phenomenon.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap