Multi-blade roots pump rotor molded line

A rotor profile and rotor technology, which is applied to pumps, pump components, rotary piston pumps, etc., can solve the problems of profile design limitations and inability to use, and achieve a wide range of parameter values, high area utilization coefficient, flow rate, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

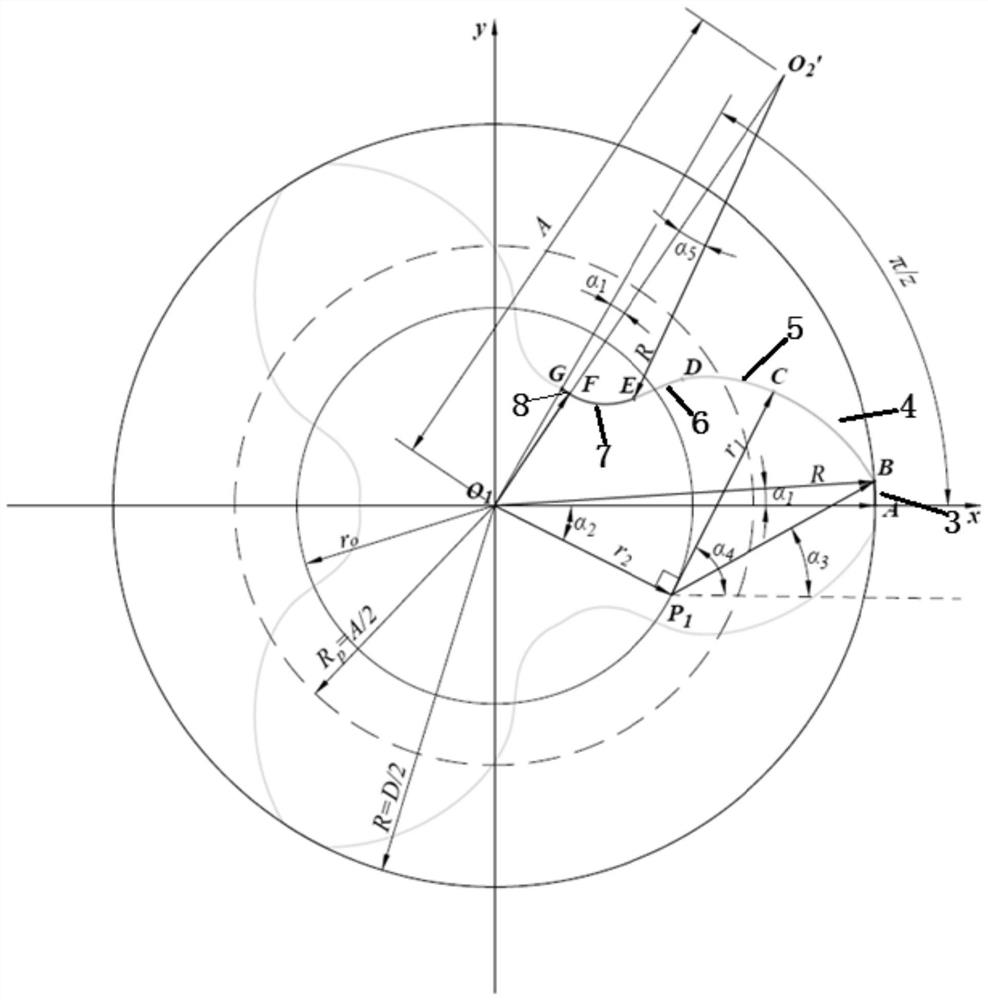

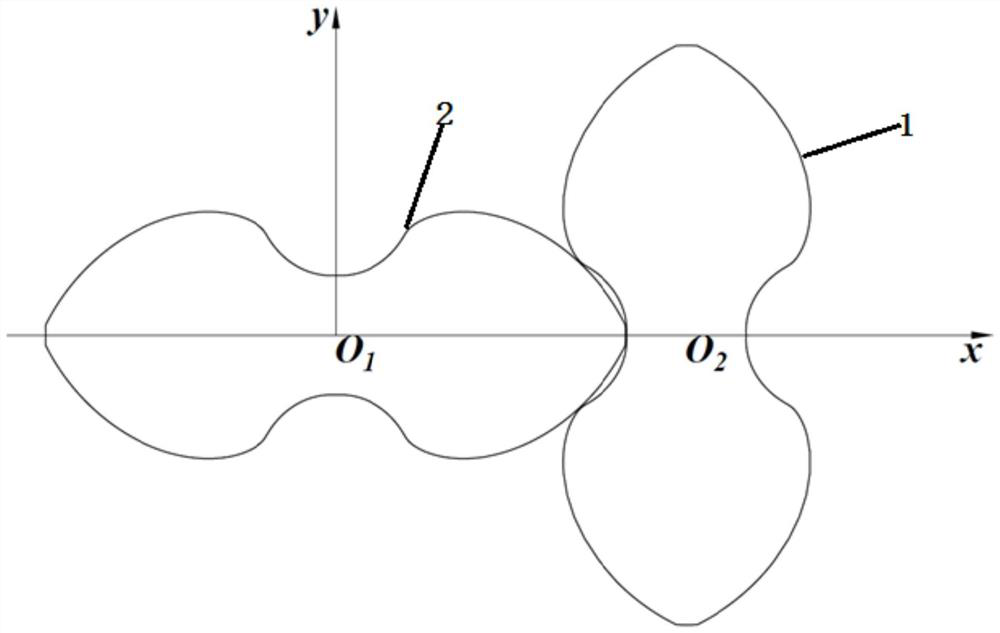

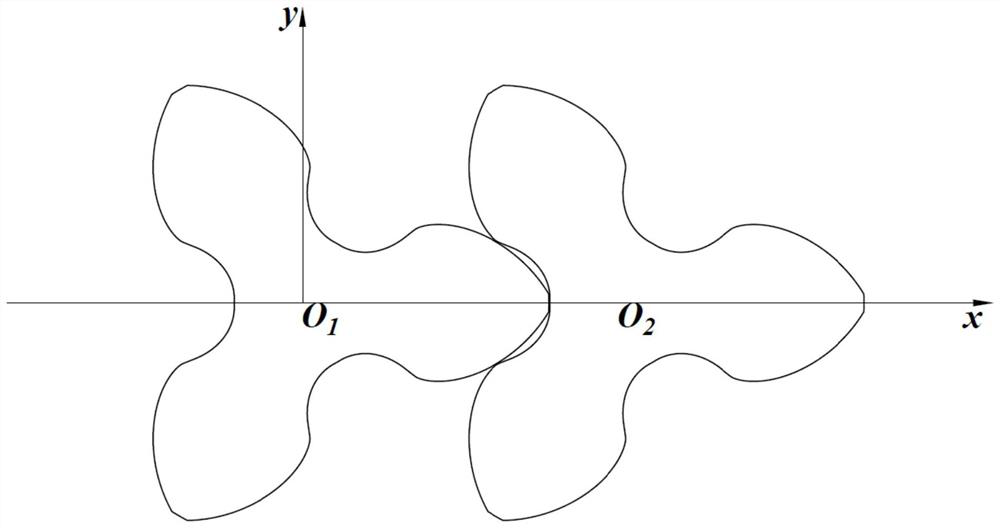

[0050] This embodiment relates to a multi-lobe Roots pump rotor profile, such as Figure 1-8 shown. The multi-lobe Roots pump described in the present application includes two completely consistent shapes and center-symmetrical main and driven rotors about their own rotor centers, and the rotor is z (z≥2 and z∈N * ) leaf type, no eccentric quality. The rotor profile consists of sequentially connected tooth tops and tooth roots. In this embodiment, the structure from the addendum to the dedendum of a single rotor will be described with reference to the drawings. The profiles of the rotor include arcs, arc envelopes, rolling arcs, point meshing cycloids, and involutes.

[0051] Among them, from the top of the tooth to the root of the tooth, there are tooth top to roll circular arc AB section, circular arc BC section, involute CD section, circular arc envelope DE section, point meshing cycloid EF section, and tooth root to roll circular The arc FG segment consists of these si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com