A twisted-lobe Roots rotor and its design method, compressor and expander

A design method and rotor technology, applied in the direction of machine/engine, rotary piston machine, design optimization/simulation, etc., can solve the problems of single parameter, increase of twisted-blade Roots rotor profile, limited area utilization, etc. The effect of improving the area utilization coefficient, improving the thermodynamic performance, and solving the problems of miniaturization and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

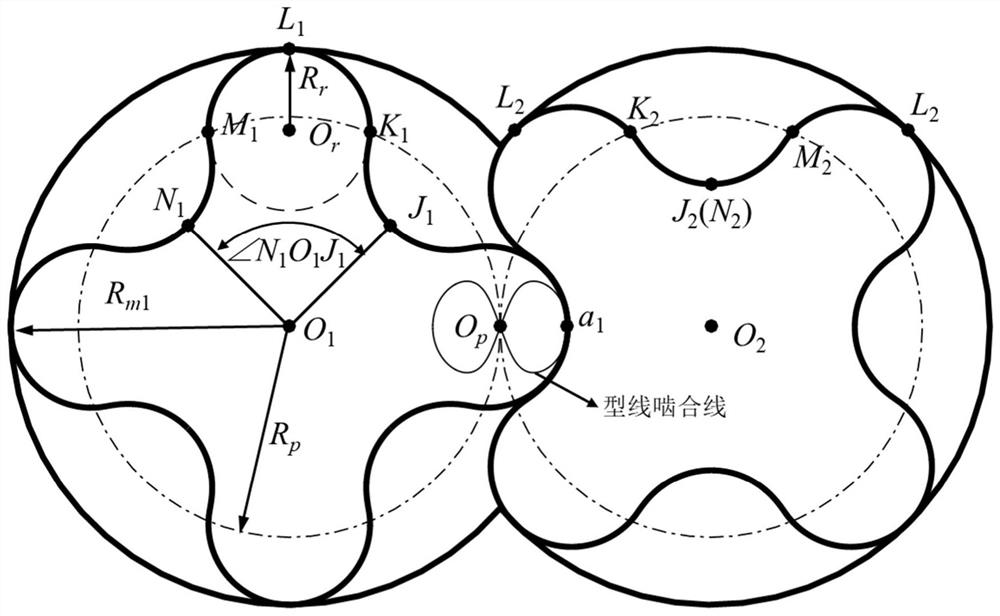

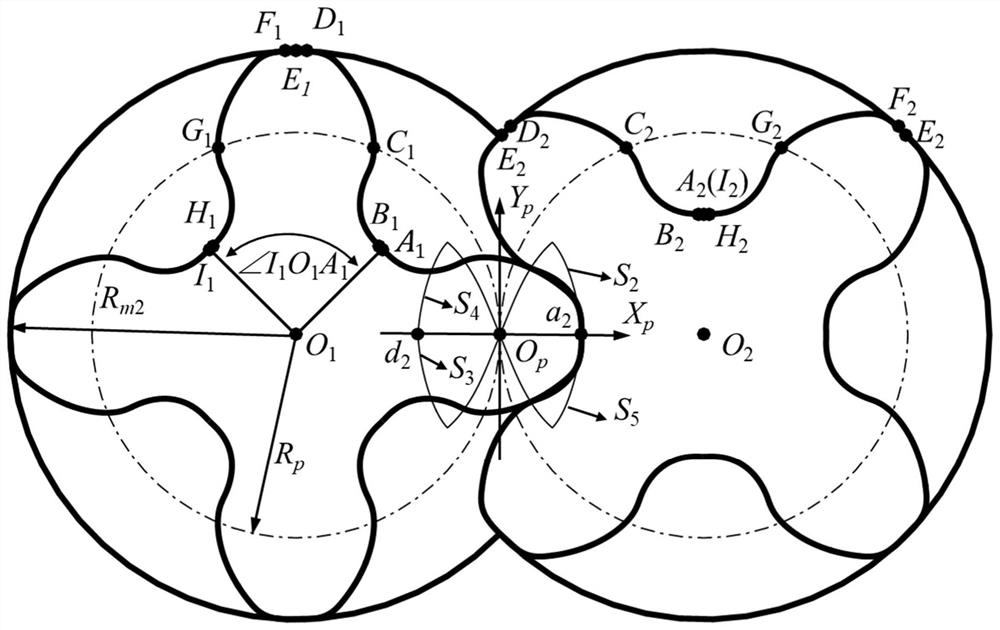

[0068] A design method for a twisted-lobe Roots rotor, comprising the following steps:

[0069] 1) Determine pitch circle radius R p , the target aspect ratio and the number of teeth n. In this example, Take 1.4.

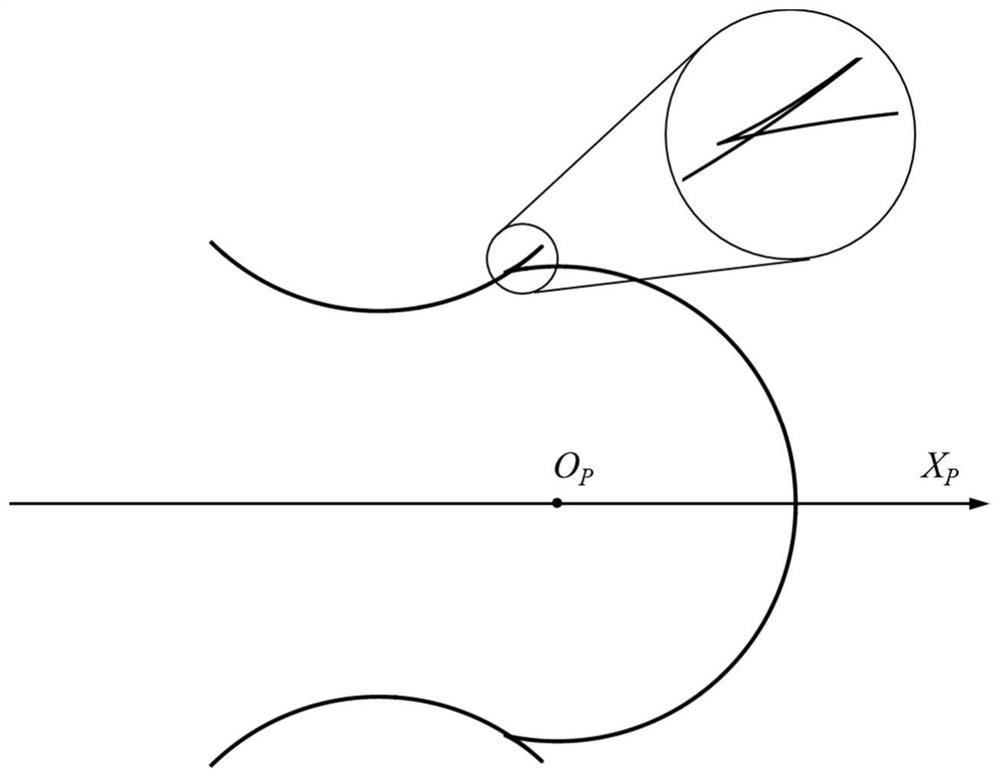

[0070] 2) Generate meshing line bus S 1 , S 1 is the arc segment L of the original arc type line 1 m 1 Corresponding meshing lines, such as Figure 4 shown. S 1 aspect ratio satisfy is the maximum diameter-to-spacing ratio when the tooth curve just does not produce undercutting phenomenon, when n=4, It can be seen that the original arc profile cannot reach the target diameter-to-spacing ratio requirements. in this example Take 1.32. Let the tangent point of the yin and yang rotor pitch circle be O p , in the coordinate system X p o p Y p Medium, L 1 m 1 Segment corresponding to meshing line S 1 parametric equation for:

[0071]

[0072] in, is the arc segment L 1 m 1 The tooth curve equation, is the corresponding meshing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com