Low-quality waste heat recycling system

A waste heat recovery and low-quality technology, which is applied in the field of industrial waste heat utilization, can solve the problems of poor oxidation resistance, high temperature resistance, smaller blade rotation force, and lower energy utilization rate, and achieve stable work, stable air output, and area utilization. The effect of increasing the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

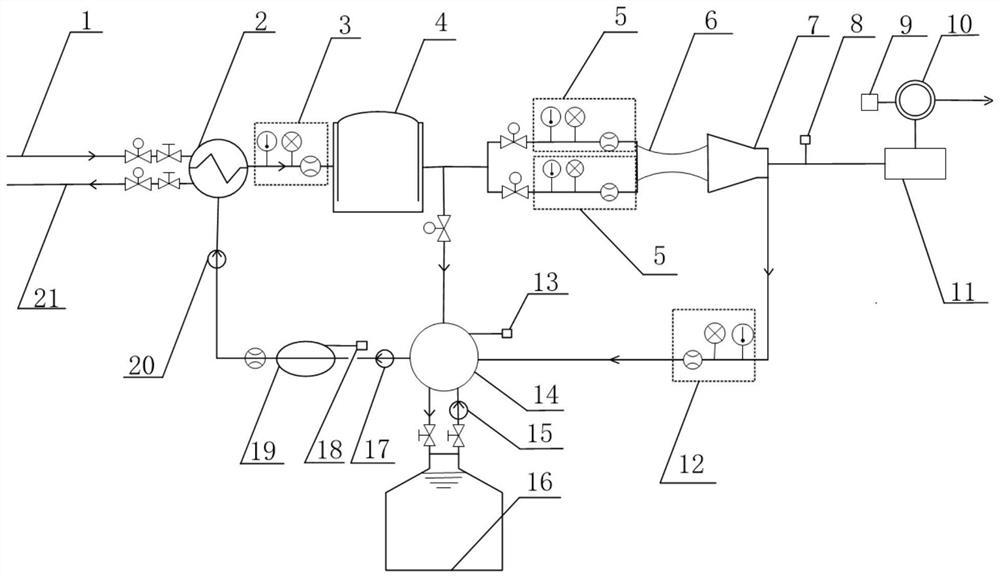

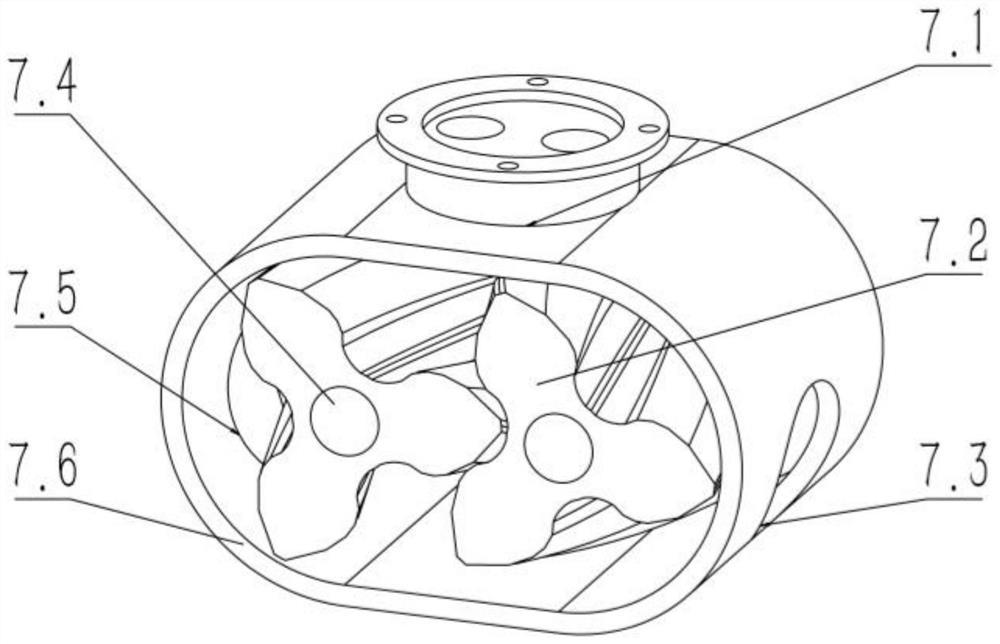

[0022] The present invention provides a low-quality waste heat recovery and utilization system (referred to as the system, see Figure 1-2 ), characterized in that the system includes a waste heat recovery system and a circulation system;

[0023] The waste heat recovery system includes a waste heat intake pipeline 1, a heat pipe steam generator 2 and a waste heat outlet pipeline 21; An electric valve and a shut-off valve are provided, and the other end is connected to the waste heat inlet of the heat pipe steam generator 2, and the liquid working medium in the heat pipe steam generator 2 is vaporized into working medium steam by using the heat of the waste heat gas; the waste heat outlet pipeline One end of 21 is a waste heat outlet, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com