Improved I-shaped aluminum connecting structure for aluminum alloy building

A connection structure, I-shaped aluminum technology, applied in the direction of connection components, rod connection, mechanical equipment, etc., can solve the problems of complex manufacturing process of three-dimensional connection plate, troublesome construction and installation, etc., to improve building construction efficiency, strengthen resistance strength, The effect of environmental safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

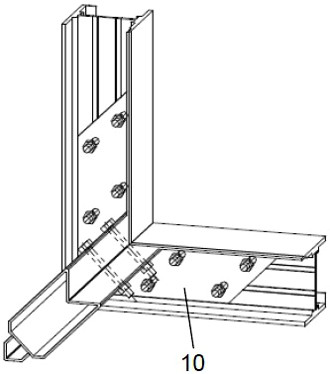

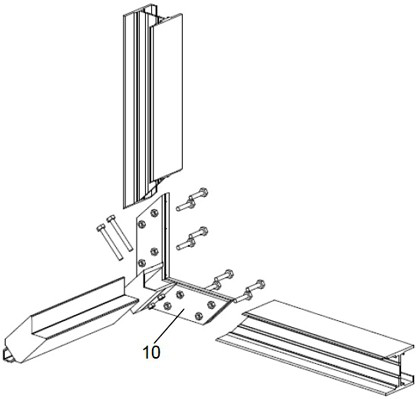

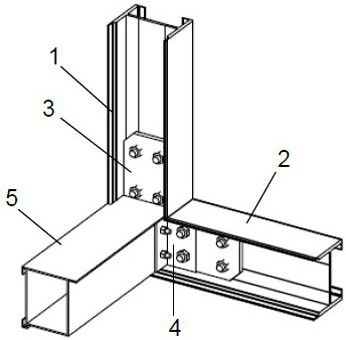

[0035] see Figure 3 to Figure 6 , the present invention provides an improved aluminum alloy building I-shaped aluminum connection structure, which is mainly composed of two or more I-shaped aluminum components, a triangular connecting plate 3, an overlapping plate 4, a bottom beam 5 and a fixed connecting piece, wherein the I-shaped aluminum There are a first I-shaped aluminum component 1 and a second I-shaped aluminum component 2 in the shaped aluminum component.

[0036] Such as image 3 and Figure 4 As shown, the vertical lower end of the first I-shaped aluminum member 1 has an oblique cut as the connection end, and the horizontal inner end of the second I-shaped aluminum member 2 has an oblique cut as the connection end.

[0037] The triangular connecting plate 3 is provided with an upwardly extending connecting portion and a laterally extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com