Combined heat exchanger and refrigerator

A technology of heat exchangers and refrigerators, which is applied in household refrigerators, refrigeration components, lighting and heating equipment, etc. It can solve the problems of refrigerant flow and refrigeration capacity cannot be adjusted, and achieve the effect of convenient defrosting and reducing the generation of frost layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

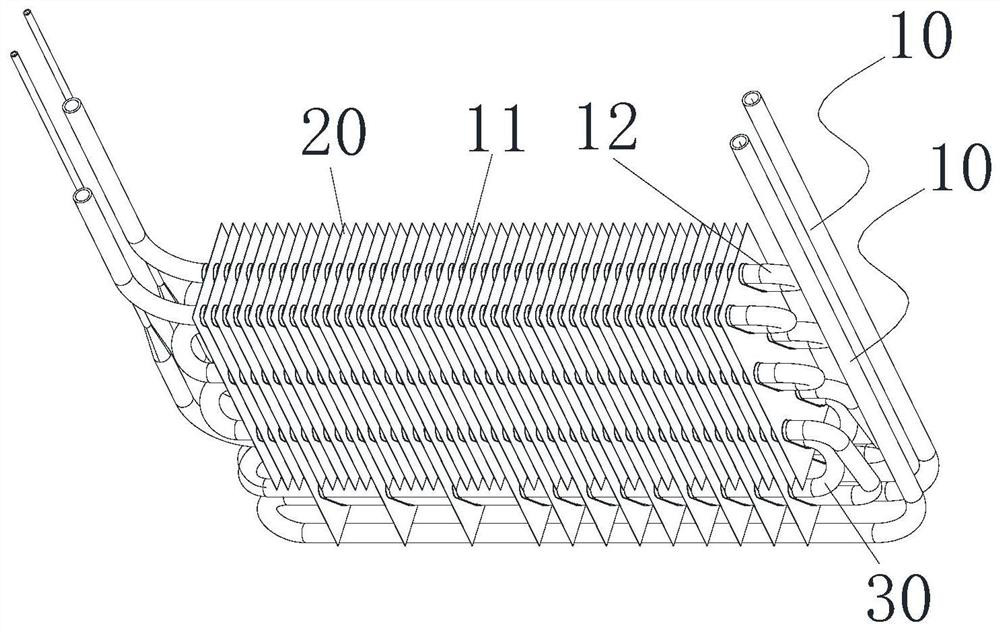

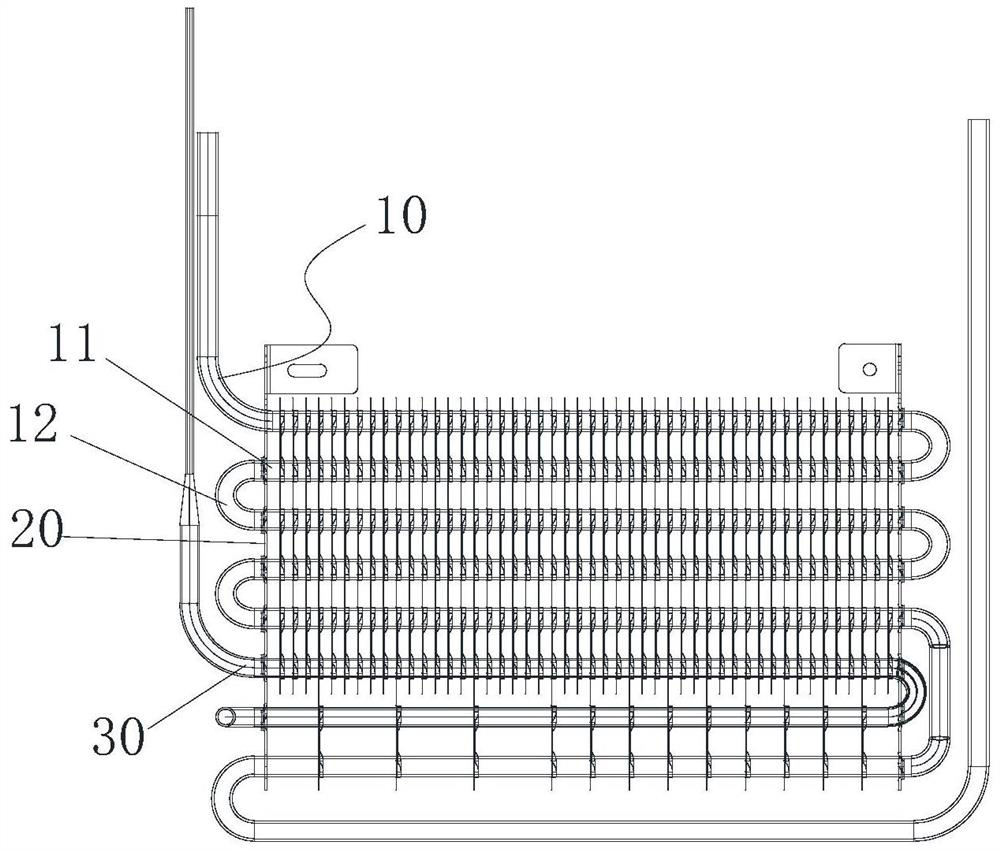

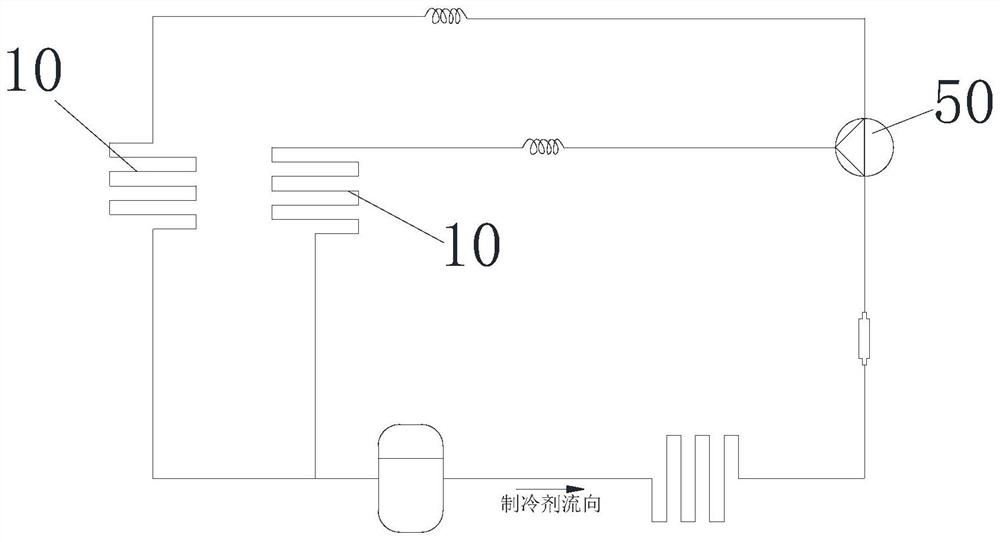

[0022] Such as figure 1 and figure 2 As shown, the present invention discloses a heat exchanger, including heat exchange coils 10 and cooling fins 20, heat exchange coils 10 are at least two groups, all heat exchange coils 10 are stacked, each group of heat exchange discs The tube 10 is an independent heat exchange pipeline; the cooling fins 20 are installed on the heat exchange coil 10 . The heat exchanger of the present invention is provided with multiple sets of heat exchange coils 10, and each set of heat exchange coils 10 is an independent heat exchange pipeline. Therefore, different heat exchange coils 10 can be controlled to exchange heat independently according to specific conditions. Or heat exchange at the same time, so as to adjust the cooling capacity, reduce the generation of frost layer, facilitate defrosting, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com