Water tank mounting structure

A technology for installing structures and water tanks, which can be used in cooking utensils, household utensils, applications, etc., and can solve problems such as large space occupation, easy damage, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiment represented by accompanying drawing:

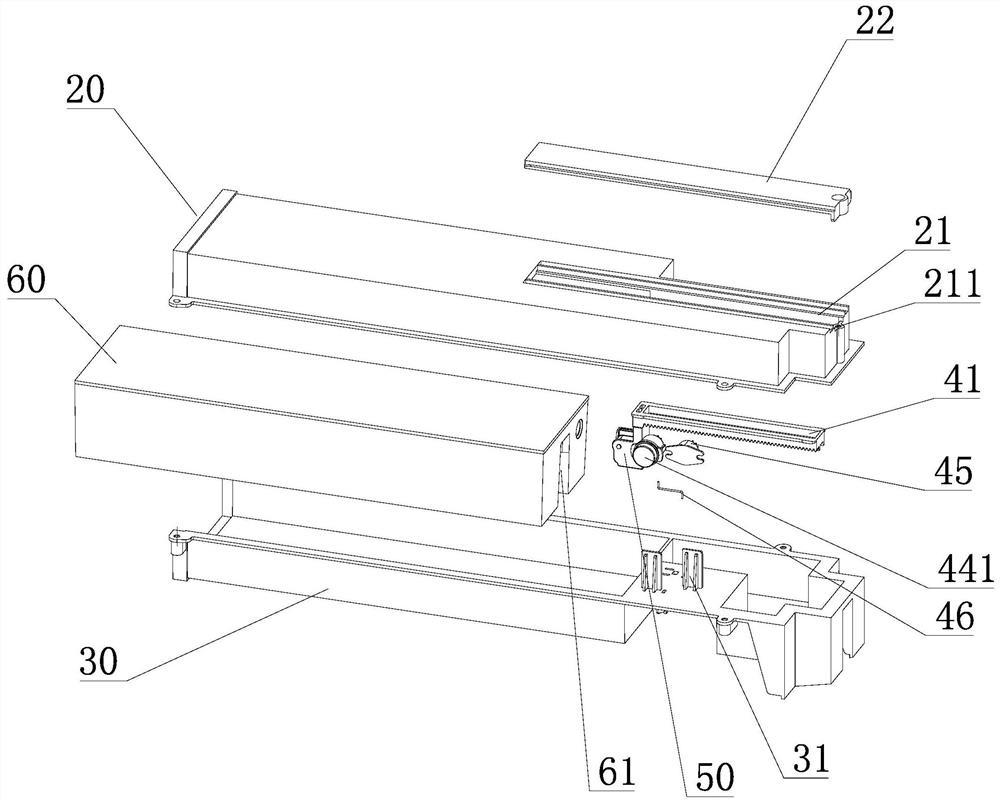

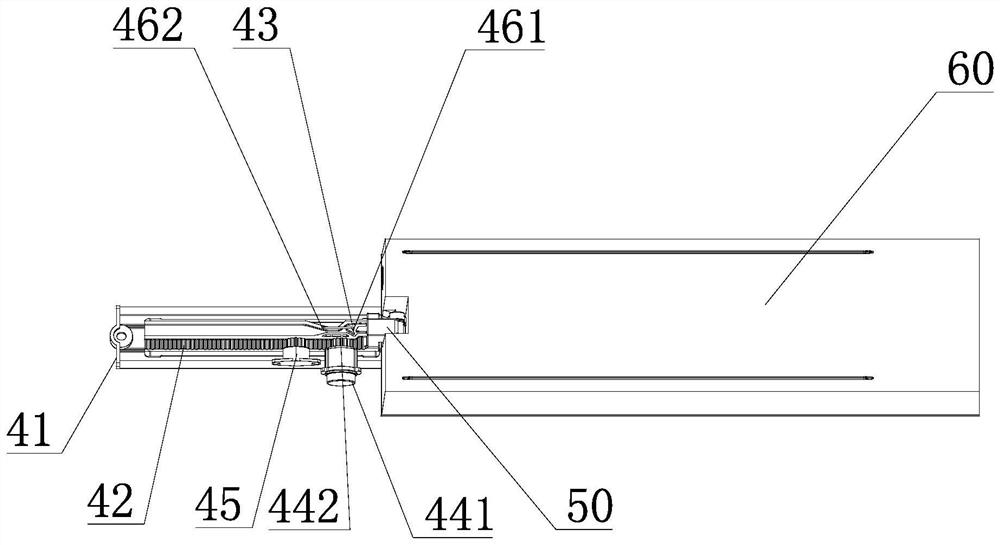

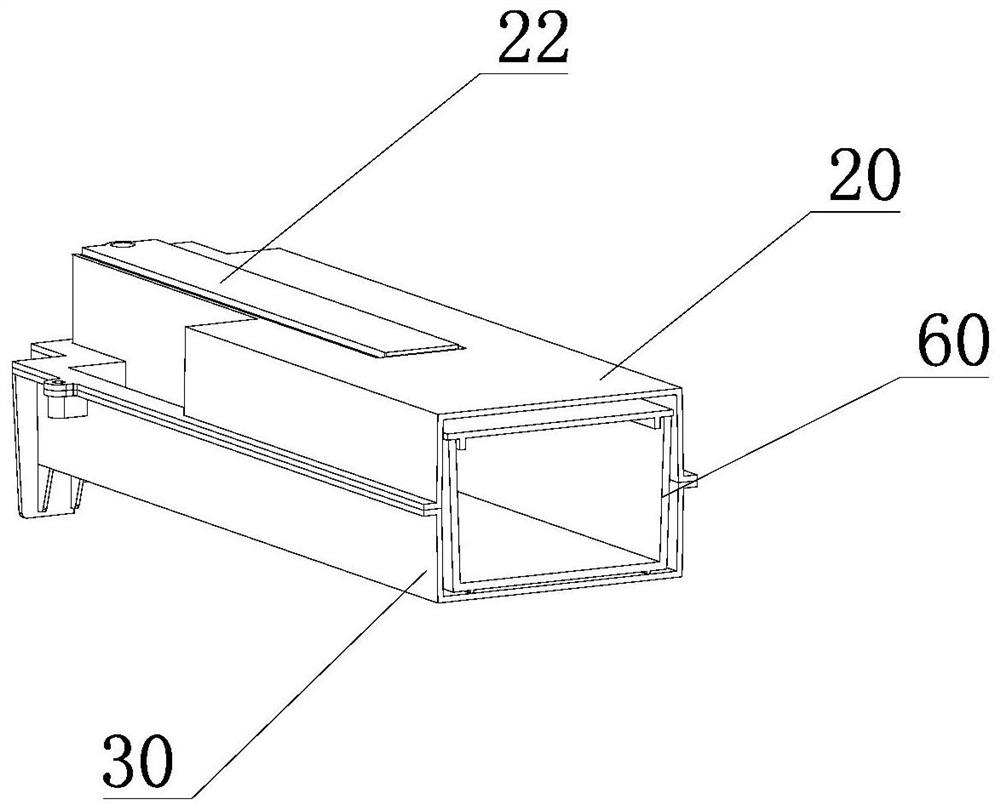

[0030] Such as Figure 1-12As shown, the present embodiment discloses a water tank installation structure, which is mainly used in a steamer, which includes a water tank 60 and a mounting seat. The mounting seat is composed of an upper cover 20 and a base 30. The cavity of the water tank 60, the water tank 60 is movably installed in the cavity, and can slide along the horizontal direction; the upper part of the mounting seat is provided with a locking pop-up mechanism, and the locking pop-up mechanism is stored in the process of the water tank 60 moving forward and locking. force, and release the force in the process of unlocking the water tank 60 to provide pop-up power for the water tank 60; the locking pop-up mechanism is provided with a connecting mechanism 50, and the water tank 60 can be connected with the connecting mechanism 50 in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com