Mesh-screen-type dustpan and production and preparation process thereof

A preparation process and dustpan technology, which is applied in the field of screen-type dustpan and its production and preparation process, can solve the problems of low aesthetics, affecting the effect of screening materials, and reducing the tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described below with reference to the accompanying drawings.

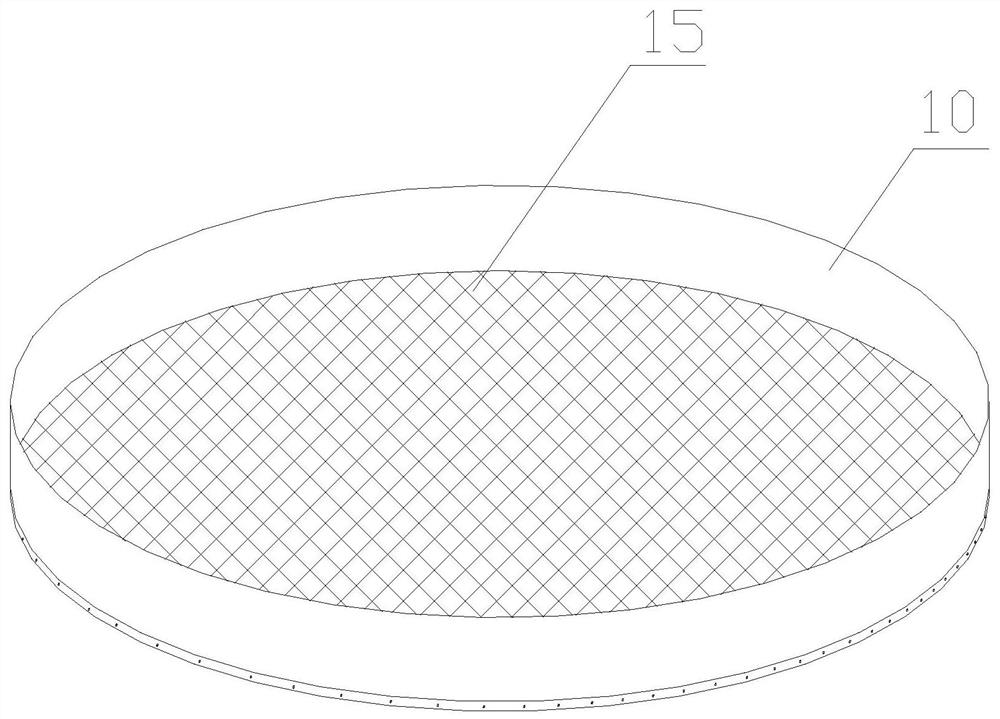

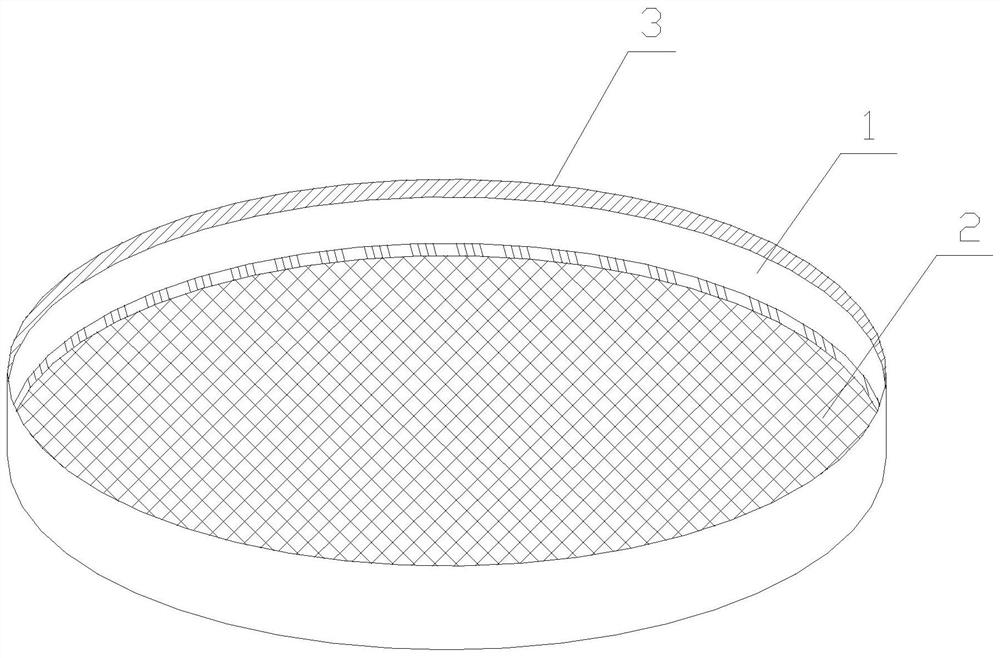

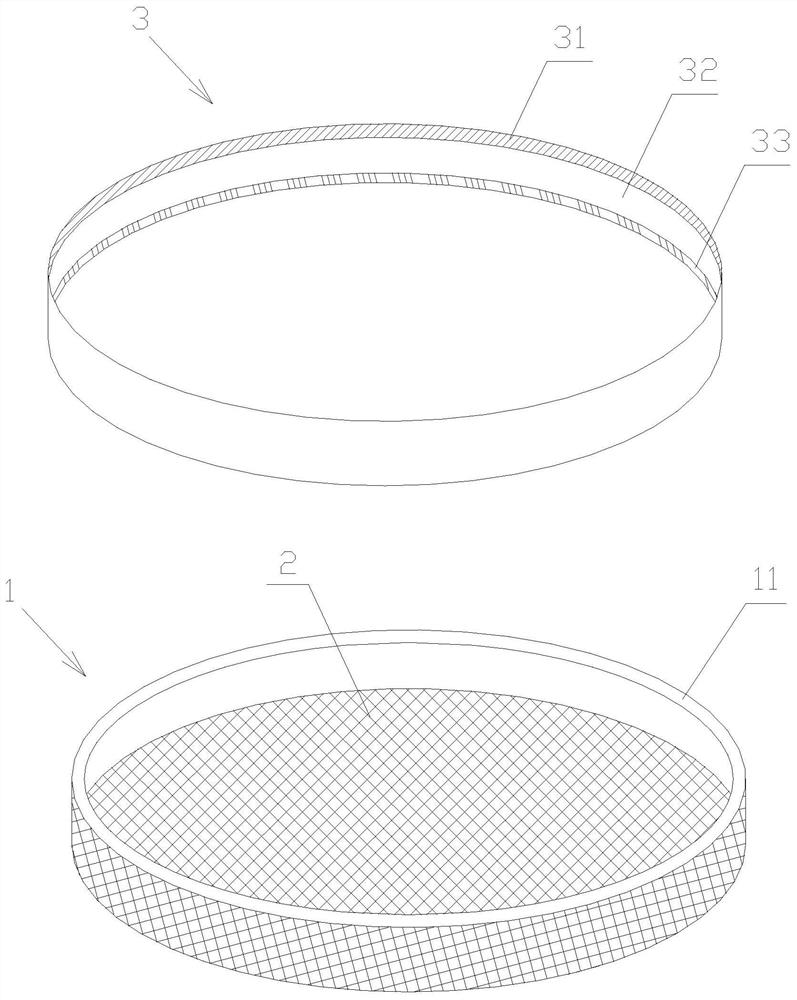

[0035] Such as Figure 2 to Figure 9 As shown, a mesh-type dustpan includes an intermediate ring 1, a screen 2 and an outer ring cover 3. The upper and lower side walls of the intermediate ring 1 are respectively recessed to form an upper inner groove 11 and a lower inner groove. The inner groove 12, the screen 2 is tightly covered on the middle ring 1, and is welded and fixed with the outer wall of the middle ring 1; the upper and lower parts of the outer ring cover 3 are respectively bent inward Provided that an upper bending groove 31 and a lower bending groove 32 are formed, an open embedding cavity 33 is formed in the middle of the outer ring cover 3, and the middle ring 1 is movably embedded in the outer ring cover 3. In the cavity 33, and the upper inner groove 11 of the intermediate ring 1 is adapted to be movably embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com