Closed collection and ecological treatment system suitable for organic garbage in multi-storey and high-rise building

A technology for ecological treatment and organic waste, applied in construction, organic fertilizers, indoor sanitary pipeline installations, etc., can solve the problems of manual sorting, heavy cleaning and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

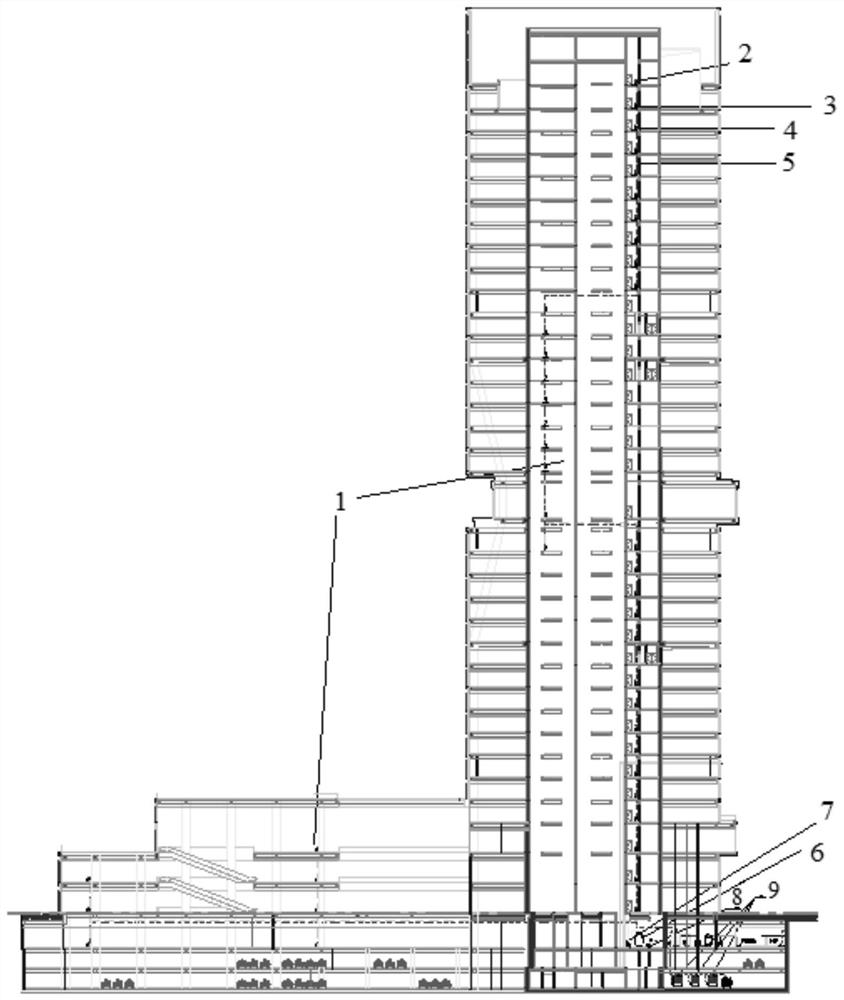

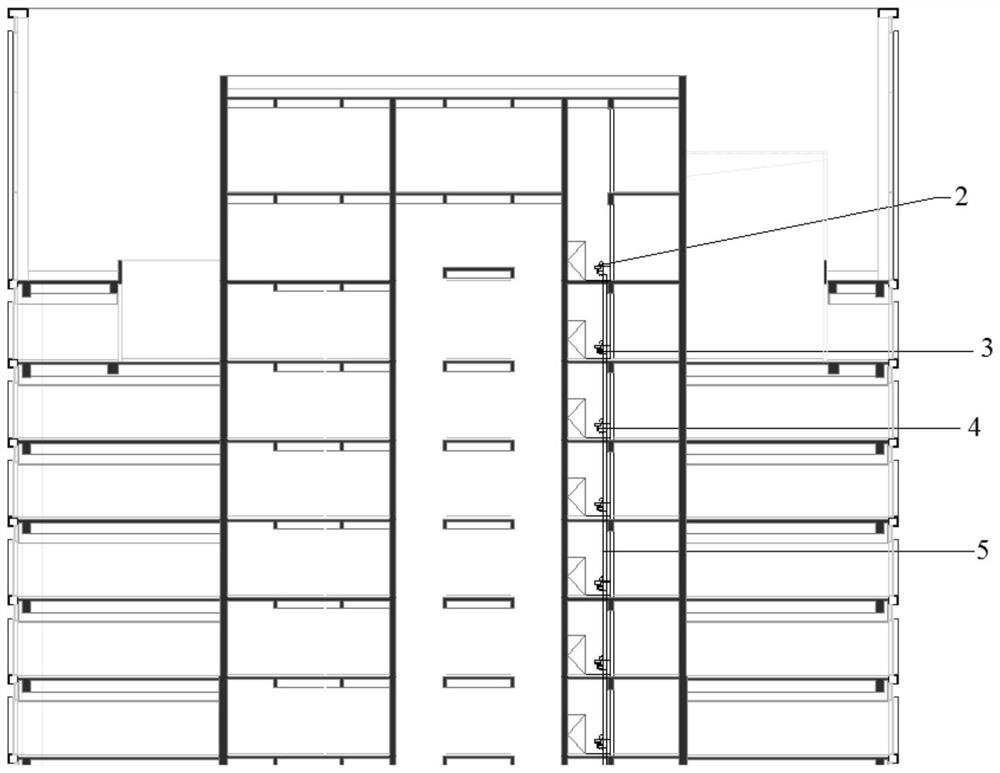

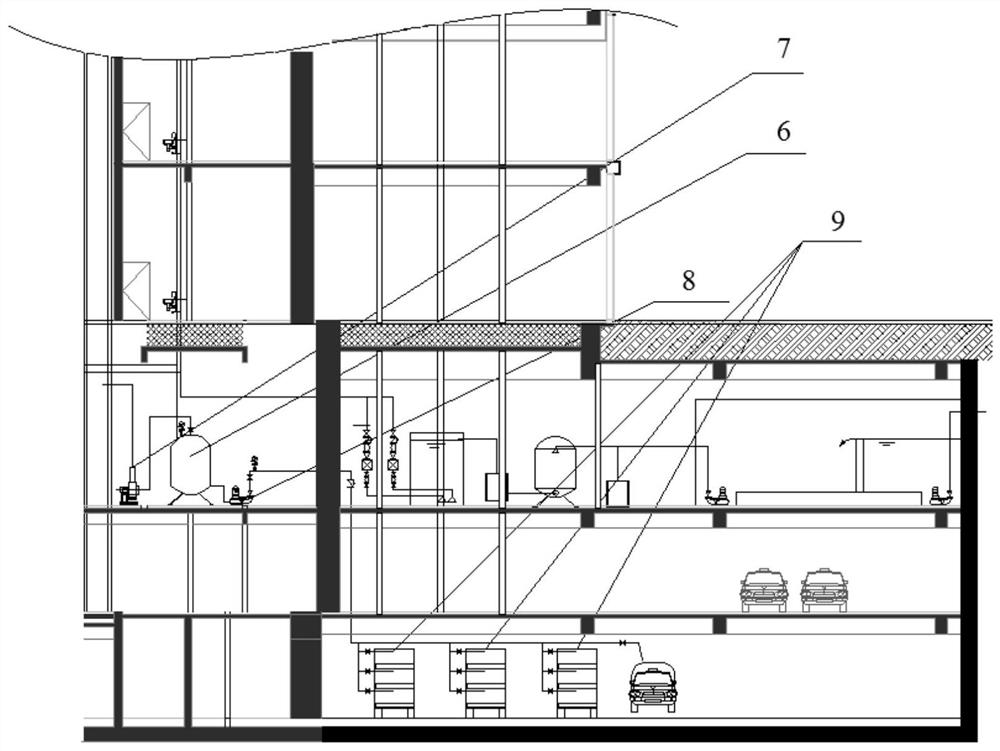

[0041] This embodiment proposes a closed collection and ecological treatment system suitable for organic waste in multi-storey and high-rise buildings. For its structure, see Figure 1-Figure 3 As shown, it includes a collection water tank 2, a pulverizer 3, a vacuum collection mechanism and an ecological treatment mechanism arranged in the building main body 1, wherein the feed port of the pulverizer 3 is connected to the bottom outlet of the collection water tank 2, and the discharge of the pulverizer 3 The outlet is connected to the feed end of the vacuum collection mechanism, and the discharge end of the vacuum collection mechanism is also connected to the ecological treatment mechanism.

[0042] see you again figure 1 As shown, the collection water tank 2 is funnel-shaped, and the collection water tank 2 of this shape can more conveniently collect the wet garbage dumped. The outlet at the bottom of the collection tank 2 is connected to the feed port of the pulverizer 3 t...

Embodiment 2

[0048] On the basis of embodiment 1, this embodiment further adopts the following design:

[0049] see you again Figure 4 As shown, an inclined baffle 11 is installed in the feed pipe 10, and one end of the baffle 11 is rotatably connected with the inner wall of one side of the feed pipe 10 through a pin, and the other end can be against the opposite side of the feed pipe 10. The inner wall is also provided with a torsion spring between the pin shaft and the baffle 11. The setting of the torsion spring can ensure that the baffle 11 is free when the baffle 11 is not under pressure or when the pressure does not exceed the torsion provided by the torsion spring. The end can be against the inner wall of the feeding channel, and then a simple sealing is performed on the feeding channel, so as to prevent the smell from the poured wet garbage from returning to the inside of the building main body 1 through the feeding pipe 10, so as to better realize the Closed collection of wet wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com